Nigerian Electrical Cables: How Much Do They Cost?

Nigerian Electrical Cables: How Much Do They Cost?

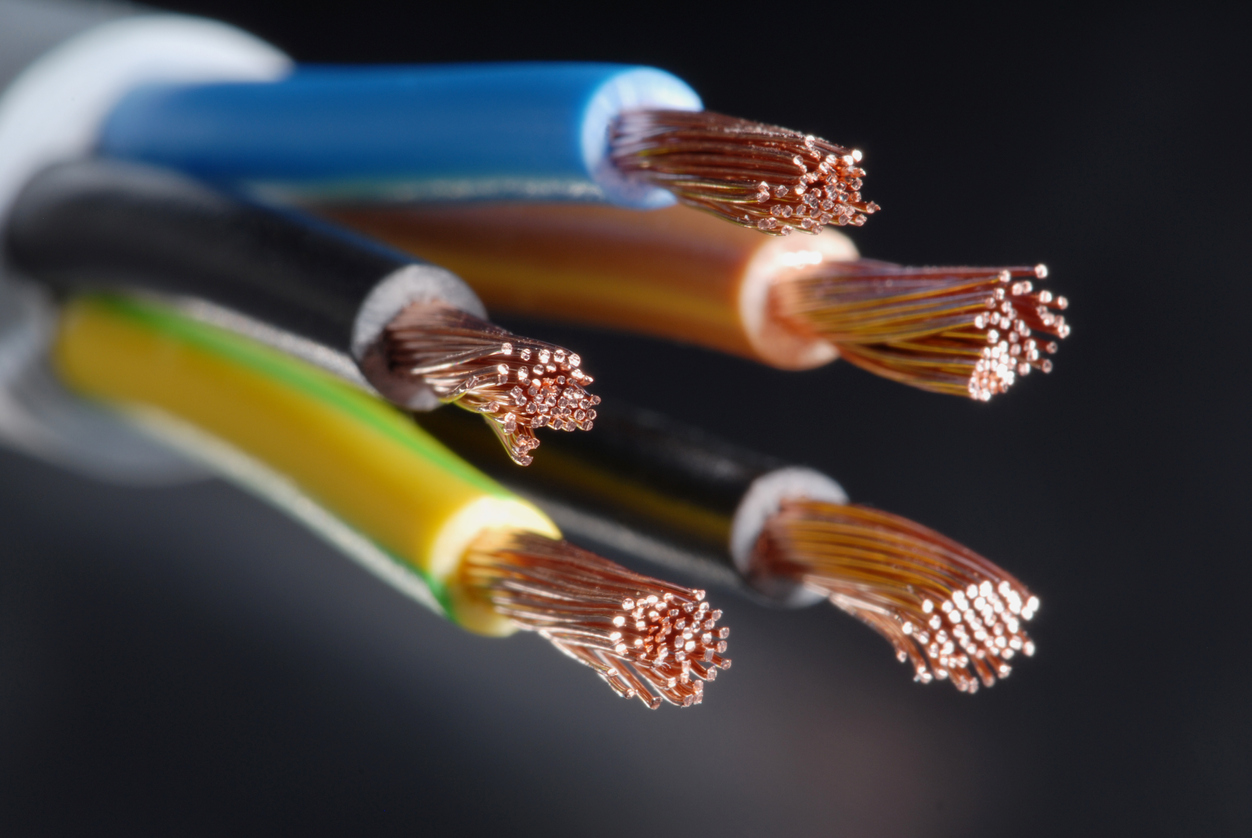

When it comes to electrical cables, there are two main types you’re bound to run into: solid and stranded. Both of these cable types have their advantages and disadvantages, which can make them costlier or cheaper than they should be depending on the situation. Let’s take a closer look at the cost of both cable types in Nigeria.

Solid Core Electrical Cables

As the name suggests, solid core cables are made up of a solid core wire wrapped in a sheath made of plastic or PVC. This provides increased flexibility to the wire, which is essential for tight bends and less strain on the cable itself. Solid core wires are available in a variety of colours, which makes them easy to recognise inside an electrical installation. The cost of solid core electrical cables isn’t too different from that of stranded core cables, but there are a few important factors to take into account. First of all, the larger the diameter of the cable you need, the more expensive it is going to get. The cost of solid core copper cable goes up with the size of the wire you need, and the rate at which you use it. Therefore, if you need to install a high-power two-way power circuit, you can expect to pay $500 per 1km of cable. If you need to run a single single-pole circuit, the cost goes up to $150 per 1km of cable.

Stranded Core Electrical cables

Stranded core electrical cables are made up of many thin strands of wire wound tightly together inside a coloured sheath. As opposed to solid core cables, stranded core wires are easy to pull apart, which is useful if you need to make tight bends in your electrical installation. The main difference between the cost of stranded and solid core wires is the coating process. While solid core wires are usually bare copper, stranded core wires are usually covered in PVC. This makes the process more complicated, so expect to pay about 10% more for stranded core wires than for solid core cables of the same size. Apart for that, the cost of stranded core wire is also affected by the number of strands in the cable. Strands come in four different sizes: 10, 12, 14 and 16AWG. 10AWG and 12AWG are the most cost-effective, as they offer sufficient power to run a low- or mid-power circuit without the risk of overheating. 14 and 16AWG are more expensive and are only used in high-power applications. If you need to run a high-power circuit, you would have to use solid core cable, which comes at a premium.

Solid Armour Electrical Cable

Solid armour cables are similar to solid core wires in the solid core type, but have the added benefit of being armoured. This means that the cable is covered in a layer of Kevlar, which makes it much harder for it to get damaged. Armoured cables usually come in one of three types: solid, armoured and hybrid. Solid armour cables are basically solid core cables with a Kevlar sheath, while hybrid cables are Kevlar-coated solid core wires. The main difference between the cost of armoured and solid core cables comes down to how armoured the cable is. Hybrid cables are coated with either a hybrid or a combination of hybrid and Kevlar, which affects the price. Hybrid cables are more expensive than solid or armoured cables.

What’s the difference between electrical cables?

– Solid core cables are cheaper than stranded core ones and bare copper wires are used in them. – Stranded core cables are cheaper than solid core ones as the sheath is made from plastic/vinyl. – Solid armour cables are cables that are covered in Kevlar to make them durable. – Hybrid cables are cables that have either a hybrid or hybrid/Kevlar sheath and are coated in one of the two. – Solid core wires are used to feed low- and mid-power circuits and are used with 4, 6 and 8AWG. – Stranded core wires are used for high-power circuits and are used with 12, 14 and 16AWG. – Solid core wires are used for indoor circuits and are often used in industrial applications. – Stranded core wires are used for outdoor circuits and are often used in residential applications.

Repairs and Maintenance of Electrical Cables

Repair and maintenance costs of electrical cables are relatively low as compared to the cost of installing new cables. This is because the wires inside an electrical cable are accessible and can be replaced without having to cut through the walls inside a building. However, the lifespan of an electrical cable is comparatively short as compared to a copper wire. This means that cables have to be repaired more often and need to be replaced sooner than copper wires. The life expectancy of electrical wires depends on the type of cable you’re using. Coated cables, such as armoured and hybrid cables, have a shorter life expectancy than bare copper cables. Solid core cables also have a relatively short lifespan as compared to stranded core ones as the coating is made from PVC. Solid core cables have to be repaired sooner due to the corrosion and damage on the wires. Stranded core cables also have to be repaired sooner due to the number of strands. Hybrid and armoured cables have a life expectancy of about 20 to 30 years.

Stranded Armour Electrical Cable

Armoured cables have been around for a long time, but they are rarely used today. The main reason for this is that armoured cables are expensive as compared to solid core ones, which makes it impractical to use more than one every 10kms in a circuit. Solid Armour electrical cable is a combination of solid core and armoured core wires. Like solid core cables, the armoured core wires are bare copper and the solid core wires are covered in PVC. The main difference between armoured and solid core cables comes down to the cost. Hybrid cables are armoured equivalents of solid core cables but coated with a hybrid sheath, while hybrid/Kevlar cables are hybrid equivalents of stranded core cables with a Kevlar sheath. Hybrid/Kevlar cables are more expensive than hybrid cables. Hybrid/Kevlar cables also have a life expectancy of about 20 to 30 years as compared to armoured cables, which only have a life expectancy of about 5 to 10 years.

Conclusion

When it comes to electrical cables, it’s important to know the difference between solid core, stranded core, armoured core and hybrid cables. This will help you choose the appropriate cable for each application. However, the cost of each type of cable depends on the application, so you’ll need to do your research before you make a purchase. If you’re looking to buy new cables, remember that you can also rent new cables from a cable manufacturer or electrical contractor.

LEAVE A COMMENT

You must be logged in to post a comment.