Injection Moulding Polypropylene: Applications, Benefits, and Sourcing Considerations

Injection moulding polypropylene is one of the most widely used manufacturing processes in modern plastics production. Thanks to polypropylene’s durability, flexibility, and cost efficiency, it is a preferred material across industries such as FMCG, packaging, automotive, healthcare, and industrial manufacturing. For importers, wholesalers, and manufacturers operating in African and global markets, understanding how injection moulded polypropylene products are produced and sourced is essential for maintaining quality and controlling costs.

What Is Injection Moulding Polypropylene?

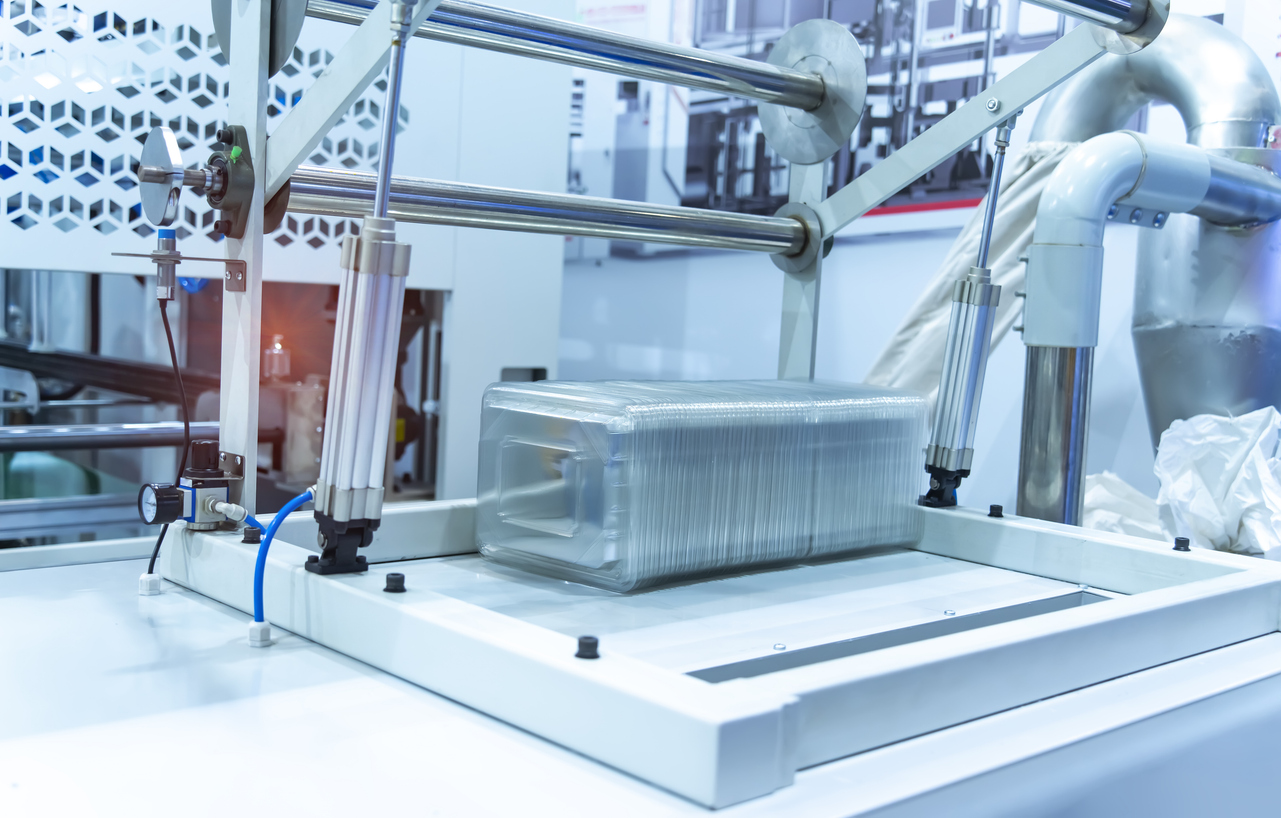

Injection moulding is a manufacturing process where molten polypropylene (PP) is injected into a mould cavity under pressure. Once cooled and solidified, the mould opens to release a finished plastic component with precise dimensions and consistent quality.

Polypropylene is especially suited to injection moulding because it flows well when heated, cools quickly, and retains strength after repeated use. This combination makes it ideal for high-volume production runs where uniformity and efficiency are critical.

Key Properties of Polypropylene for Injection Moulding

Polypropylene offers several properties that make it attractive for injection moulding applications:

-

High impact resistance and toughness

-

Lightweight yet structurally strong

-

Excellent chemical resistance

-

Low moisture absorption

-

Good fatigue resistance, ideal for hinged products

-

Cost-effective compared to many engineering plastics

These characteristics explain why injection moulding polypropylene is widely used for containers, caps, crates, automotive parts, medical disposables, and household goods.

Common Applications of Injection Moulded Polypropylene

Injection moulded polypropylene products are used across multiple sectors:

FMCG and Packaging

Food containers, bottle caps, closures, storage boxes, and reusable packaging solutions are commonly made from polypropylene due to food safety compatibility and durability.

Industrial and Logistics

Plastic pallets, bins, crates, and storage components benefit from PP’s strength-to-weight ratio and resistance to chemicals and moisture.

Automotive and Engineering

Interior trim components, battery casings, and under-the-hood parts rely on injection moulding polypropylene for heat resistance and dimensional stability.

Healthcare and Medical Supplies

Disposable syringes, specimen containers, and medical packaging frequently use polypropylene because it can withstand sterilization processes.

Wigmore Trading works with manufacturers and suppliers that produce a wide range of injection moulded polypropylene products suitable for these sectors, supporting businesses sourcing for African and international markets.

Advantages of Injection Moulding Polypropylene for Businesses

For manufacturers and distributors, injection moulding polypropylene offers several commercial advantages:

-

Scalability: Ideal for mass production with consistent quality

-

Cost efficiency: Lower material and processing costs per unit at scale

-

Design flexibility: Complex shapes, thin walls, and integrated features

-

Durability: Long product life reduces replacement and warranty issues

These benefits are particularly important for importers and wholesalers looking to supply competitive markets without compromising quality.

Challenges in Sourcing Injection Moulded Polypropylene Products

Despite its advantages, sourcing injection moulded polypropylene products can present challenges:

-

Inconsistent material grades affecting strength and finish

-

Variable mould quality leading to defects or dimensional inaccuracies

-

Limited transparency in supplier quality control processes

-

Logistics and customs delays, especially for cross-border trade

Businesses importing into Africa or exporting from Asia and Europe often face additional hurdles related to compliance, shipping reliability, and supplier vetting.

Practical Solutions for Reliable Sourcing

To overcome these challenges, businesses should focus on:

-

Working with suppliers that use certified polypropylene grades

-

Verifying moulding standards and production capabilities

-

Ensuring quality checks before shipment

-

Partnering with experienced trade and logistics specialists

Wigmore Trading can help by sourcing injection moulded polypropylene products from trusted manufacturers, managing supplier relationships, and coordinating logistics to ensure products arrive on time and meet specifications.

Why Work with Wigmore Trading?

Wigmore Trading supports businesses involved in import/export, wholesale distribution, and industrial supply across Africa and global markets. With experience in plastics sourcing, FMCG products, and industrial components, the company helps clients secure reliable injection moulded polypropylene products while reducing supply chain risk.

From supplier identification to shipping and customs coordination, Wigmore Trading offers practical support without unnecessary complexity.

Get in touch with our team to learn more about sourcing polypropylene injection moulded products for your business.

Comments are closed.