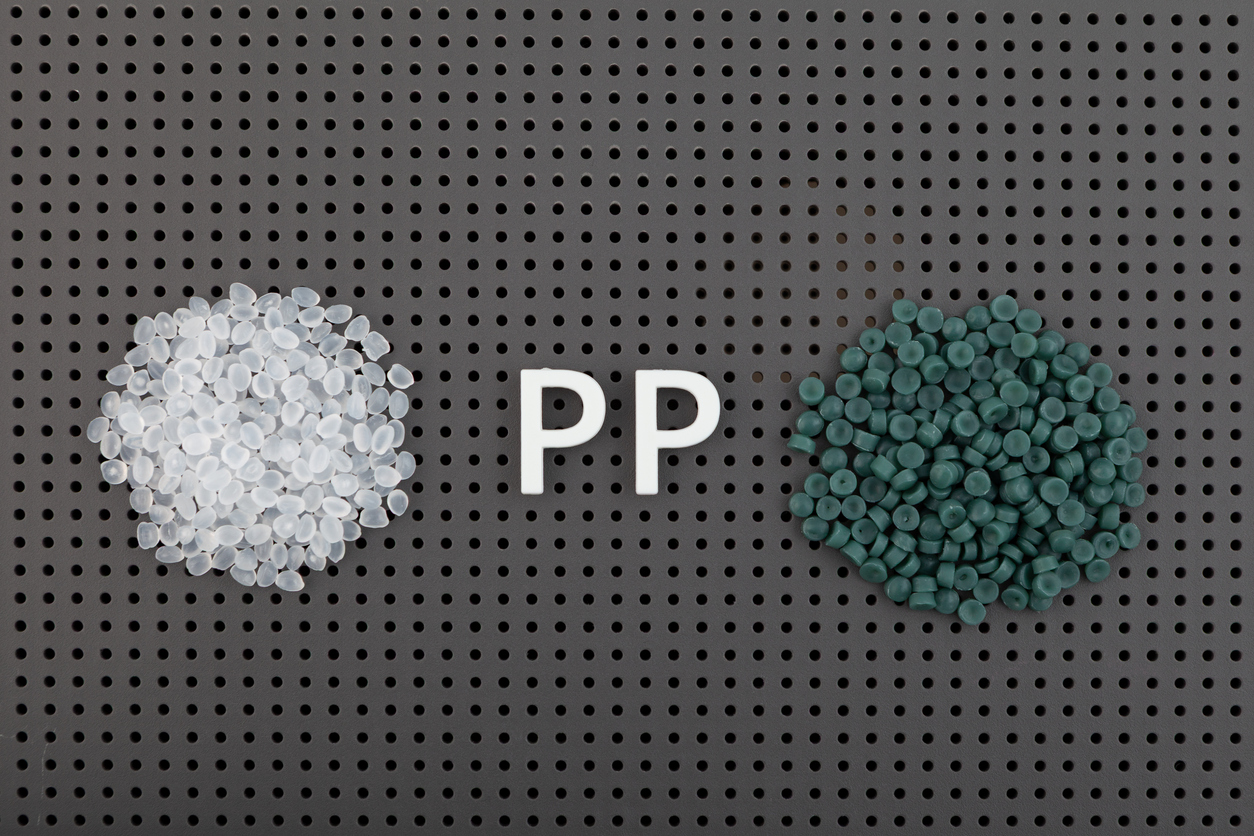

PP Random Copolymer: What It Is, Where It’s Used, and How to Source It Reliably

PP random copolymer (also called polypropylene random copolymer, PP-R, or PP-RC) is one of the most practical polypropylene grades for manufacturers who need a balance of clarity, toughness, and easy processing. It’s widely used across FMCG packaging, housewares, medical packaging, and PP-R piping systems—especially where consistent quality and repeatable conversion performance matter.

For importers and converters in Africa, the bigger challenge is often not “what is PP random copolymer?”—it’s how to buy the right grade, validate compliance, and land it on time without costly surprises. That’s where an experienced sourcing partner like Wigmore Trading can help.

What is PP random copolymer?

PP random copolymer is a polypropylene resin produced by polymerizing propylene with small amounts of comonomers (commonly ethylene, and sometimes butene) introduced randomly along the polymer chain. This structure typically improves optical properties and processing behavior versus standard PP homopolymer, making it a strong fit for transparent or glossy products and certain pressure-pipe applications.

You may also see related variants such as:

-

PP-R: common naming for random copolymer used in piping and fittings, often aligned to plumbing standards.

-

PP-RCT: a temperature-resistant PP random copolymer used where higher temperature performance is required.

Key properties that make PP random copolymer popular

Compared with PP homopolymer, random copolymers are widely associated with:

-

Improved clarity / reduced haze (better optical performance)

-

Better impact resistance (useful for packaging and consumer goods)

-

Lower heat-sealing temperature in some film applications due to a lower melting point trend versus homopolymer

-

Good chemical resistance typical of polypropylene

Common applications in manufacturing and African supply chains

1) High-clarity packaging and rigid containers

PP random copolymer is often selected for clear or glossy packaging, including rigid containers and certain film structures. For FMCG brands, better clarity can support shelf presentation while keeping resin costs and weight competitive.

2) Films (cast, BOPP, blown) and seal layers

Many converters use random copolymer grades for film applications, where a useful sealing window and appearance can matter. If you’re buying for film conversion, specify your process (BOPP vs cast vs blown) and the target MFI (melt flow index) range to avoid unstable output or sealing issues.

3) PP-R piping and fittings (hot/cold water distribution)

In building services and infrastructure, PP-R pipes and fittings are commonly made from polypropylene random copolymer. This is relevant for importers supplying construction and MEP contractors who need predictable performance and documentation.

4) Injection molding for housewares and consumer products

Random copolymer is frequently used for molded products that benefit from a balance of stiffness, toughness, and appearance, such as household storage and food-contact items (depending on grade compliance).

How to choose the right PP random copolymer grade

Buying “PP random copolymer” without a grade strategy is a common (and expensive) mistake. Use this checklist:

Match the grade to the process

-

Injection molding, blow molding, extrusion, film, thermoforming, or pipe compounds each need different flow and thermal behavior.

Define performance targets

-

Clarity/gloss requirements (packaging vs utility parts)

-

Impact performance at typical handling temperatures

-

Heat resistance needs (hot-fill, sterilization, or piping duty)

Check compliance requirements early

-

For piping, ask for documentation aligned to the standard/spec your market uses.

-

For food-contact or medical packaging, request the appropriate regulatory declarations for your destination market (and keep records for audits).

Avoid the “wrong PP type” trap

-

If the application is primarily high-impact structural, you may need impact copolymer rather than random copolymer.

Sourcing and import considerations (especially for Africa)

Even with the right grade, import performance depends on execution:

-

Consistent origin and producer: mixed lots can cause processing variability.

-

Documentation discipline: COA, MSDS, and compliance declarations should match the shipment and grade name.

-

Packaging and moisture protection: resin should arrive clean, sealed, and clearly labeled (important for converters feeding silos or hoppers).

-

Shipping and lead-time planning: choose incoterms and routing that reduce port dwell time and demurrage risk.

Wigmore Trading can help you source PP random copolymer resin with clearer grade matching, trade documentation support, and logistics coordination for African import routes.

How Wigmore Trading supports PP random copolymer buyers

Wigmore Trading works with businesses that need dependable polymer supply for packaging, FMCG distribution, construction materials, and industrial production. The team can support:

-

Grade selection based on your process and product requirements

-

Sourcing from reliable supply channels

-

Shipment planning, consolidation, and import coordination into African markets

If you’re comparing PP-R, PP-RCT, or packaging grades, contact Wigmore Trading today to streamline your sourcing.

Comments are closed.