Polypropylene Homopolymer: Properties, Uses, and Sourcing in Global Trade

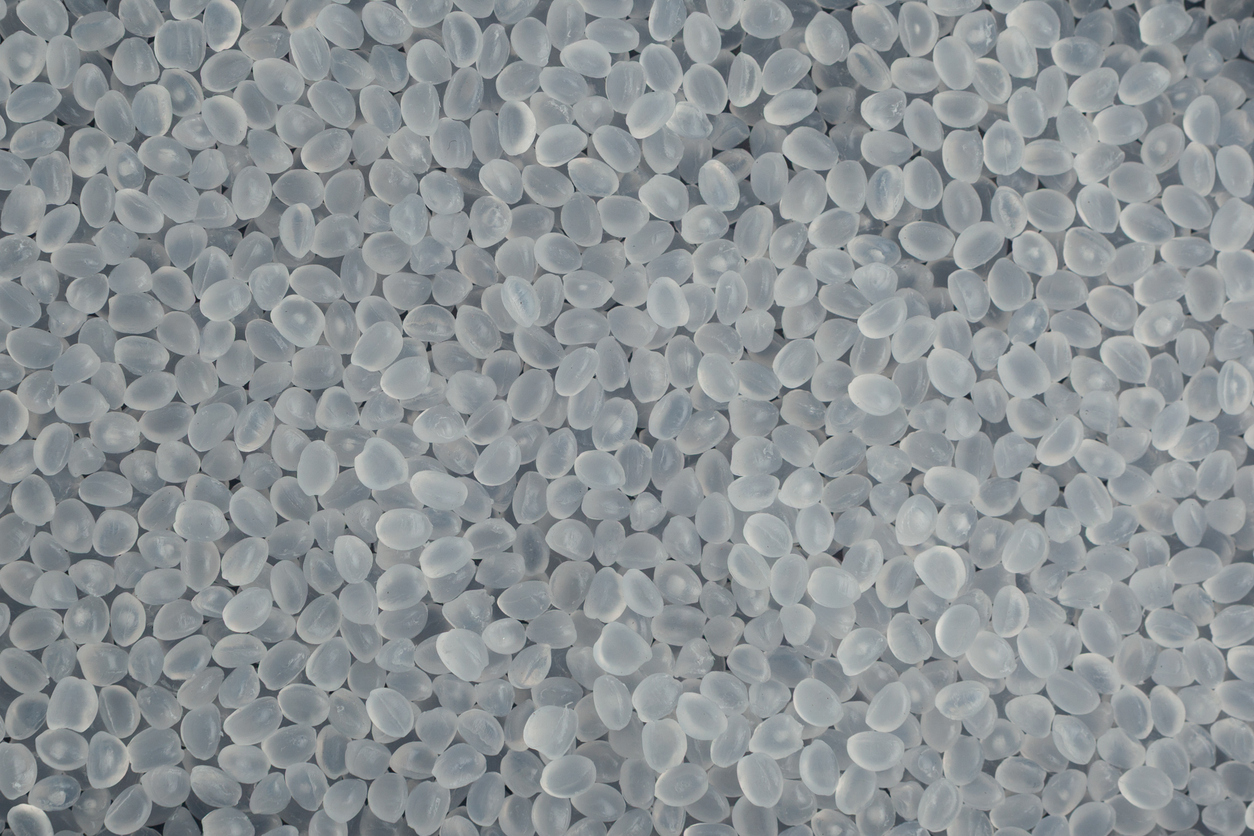

Polypropylene homopolymer is one of the most widely used thermoplastic polymers in global manufacturing and trade. Known for its strength, rigidity, and chemical resistance, it plays a critical role across industries such as packaging, automotive, construction, textiles, and FMCG production.

For importers, manufacturers, and distributors operating in African and international markets, understanding polypropylene homopolymer—and sourcing it reliably—is essential for maintaining product quality and cost efficiency. Wigmore Trading supports businesses by supplying and sourcing high-quality polymer materials tailored to industrial needs.

What Is Polypropylene Homopolymer?

Polypropylene homopolymer (PP homopolymer) is produced by polymerizing propylene monomers alone, without copolymers. This results in a material with a high degree of crystallinity, giving it superior stiffness, tensile strength, and thermal resistance compared to polypropylene copolymers.

Its consistent molecular structure makes it particularly suitable for applications where rigidity, surface finish, and dimensional stability are required.

Key Properties of Polypropylene Homopolymer

Polypropylene homopolymer is valued for a combination of mechanical and chemical properties that make it versatile across industries.

High stiffness and strength

PP homopolymer offers excellent rigidity, making it ideal for products that must retain shape under stress, such as containers and molded parts.

Chemical resistance

It resists acids, alkalis, and many organic solvents, making it suitable for chemical packaging and industrial components.

Low moisture absorption

This property supports dimensional stability and prevents degradation in humid environments—an advantage in tropical and coastal regions.

Good thermal resistance

With a higher melting point than many plastics, polypropylene homopolymer performs well in applications exposed to heat.

Lightweight and cost-effective

Its low density reduces transportation costs while maintaining durability, an important factor for bulk trade and export.

Common Applications Across Industries

Polypropylene homopolymer is used across multiple sectors due to its performance consistency and ease of processing.

Packaging and FMCG

It is widely used in rigid packaging such as food containers, caps, closures, thin-wall packaging, and household product packaging. Its food-safe grades make it suitable for edible goods.

Automotive and industrial components

Manufacturers use PP homopolymer for dashboards, battery cases, trims, and technical parts requiring stiffness and heat resistance.

Textiles and fibers

In the textile sector, it is processed into fibers for carpets, ropes, sacks, and woven packaging materials.

Construction materials

Applications include pipes, fittings, sheets, and molded construction components that require durability and chemical resistance.

Consumer goods

Products such as storage boxes, chairs, appliances, and reusable containers often rely on polypropylene homopolymer.

Challenges in Sourcing Polypropylene Homopolymer

Despite its popularity, sourcing polypropylene homopolymer presents several challenges for buyers, especially in emerging and fast-growing markets.

Quality consistency

Variations in melt flow index, purity, or additives can affect processing efficiency and final product quality.

Supply chain disruptions

Global petrochemical supply chains are sensitive to energy prices, shipping constraints, and geopolitical factors.

Regulatory and compliance requirements

Different industries require specific certifications, particularly for food-contact or medical-grade polypropylene.

Logistics and storage

Improper handling can lead to contamination, moisture exposure, or degradation before use.

How Wigmore Trading Supports Polypropylene Homopolymer Supply

Wigmore Trading helps manufacturers, importers, and distributors overcome these challenges by offering reliable sourcing and logistics solutions for polypropylene homopolymer.

The company works with trusted global producers to supply consistent-grade polypropylene suitable for injection molding, extrusion, and fiber applications. Wigmore Trading can assist with bulk procurement, quality verification, and documentation to meet regional and international standards.

With strong experience in African trade corridors and international shipping, Wigmore Trading helps businesses manage lead times, customs processes, and last-mile delivery. This ensures uninterrupted production cycles and predictable costs.

For businesses expanding into new markets or scaling manufacturing capacity, Wigmore Trading can help identify suitable polypropylene homopolymer grades based on performance requirements and budget considerations.

Polypropylene Homopolymer in African and Emerging Markets

Demand for polypropylene homopolymer continues to rise across Africa due to growth in FMCG manufacturing, packaging, construction, and automotive assembly. Governments and private investors are also encouraging local manufacturing, increasing the need for reliable raw material imports.

Access to consistent polymer supply allows manufacturers to reduce reliance on finished goods imports and improve competitiveness. Wigmore Trading supports this shift by connecting African buyers with dependable global suppliers while navigating regional trade regulations.

Choosing the Right Supplier Matters

Selecting the right polypropylene homopolymer supplier directly impacts product quality, waste reduction, and long-term profitability. Buyers should prioritize suppliers that offer traceability, technical support, and logistics expertise.

Wigmore Trading can help businesses source polypropylene homopolymer efficiently and with confidence.

Get in touch with our team to learn more about how we support polymer sourcing and international trade solutions.

Comments are closed.