Automotive Parts Import from China to UK: A Step-by-Step Business Guide

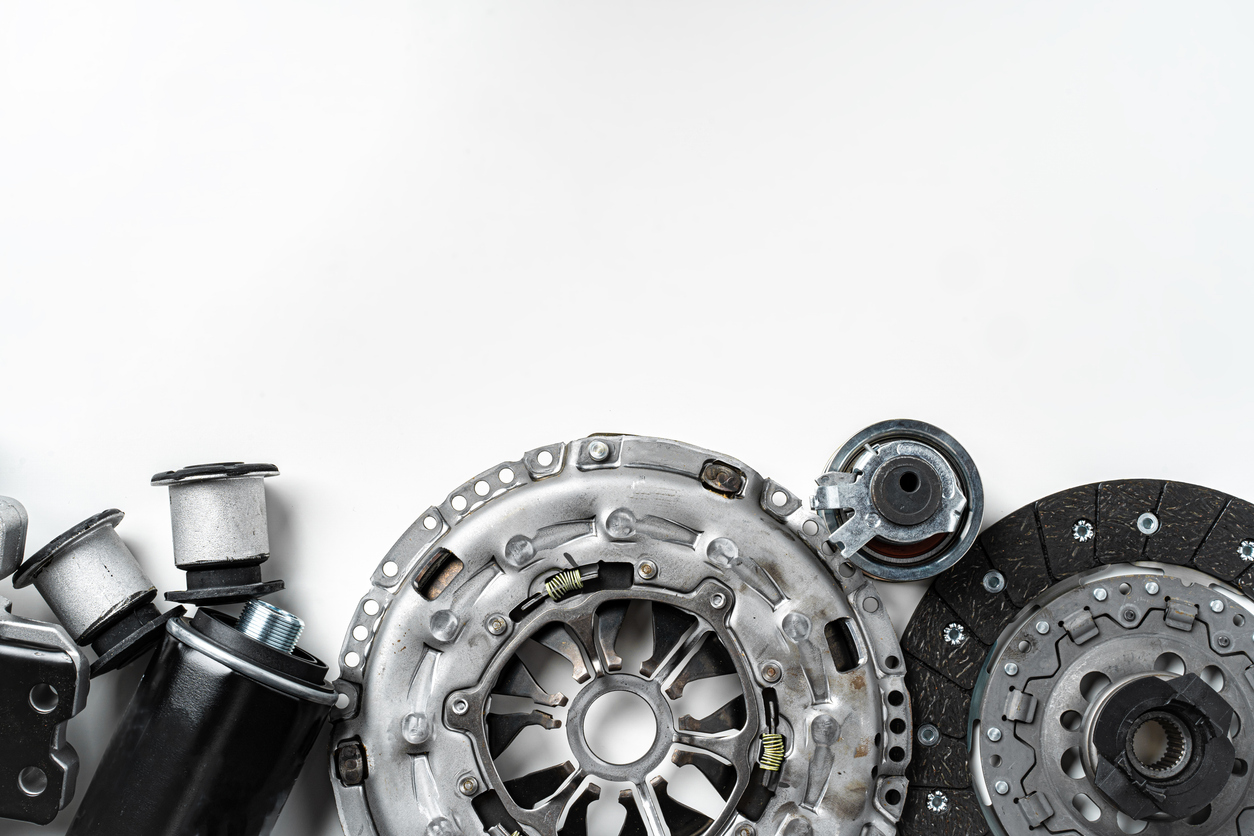

The UK automotive sector relies heavily on global supply chains, and China has become one of the most important sourcing destinations for components and spare parts. From engine components and braking systems to electronic modules and body panels, Chinese manufacturers supply a wide range of automotive products at competitive prices.

For businesses considering automotive parts import from China to UK, success depends on more than price advantages. It requires a clear understanding of supplier verification, regulatory compliance, shipping logistics, and customs procedures. This guide outlines the key considerations for importers looking to build a reliable and compliant supply chain.

Why China Is a Key Source for Automotive Parts

China is one of the world’s largest producers of automotive components. Its manufacturing ecosystem includes OEM suppliers, aftermarket specialists, and high-volume producers serving global brands. UK importers benefit from:

-

Broad product availability across mechanical and electronic categories

-

Competitive production costs

-

Scalable manufacturing capacity

-

Established export infrastructure

However, cost savings alone do not guarantee profitability. Quality control, regulatory compliance, and efficient logistics management are critical to ensuring that imported parts meet UK standards and reach customers on time.

Understanding UK Regulations for Automotive Parts Import from China to UK

Automotive components are subject to strict regulatory standards in the UK. Before placing orders, importers must confirm that products comply with all applicable requirements.

Key compliance considerations include:

Product Safety and Standards

Certain automotive parts require UKCA marking (or CE marking where applicable), particularly safety-critical components such as braking systems, lighting equipment, and seat belts. Technical documentation and conformity assessments must be available.

REACH Compliance

Parts containing chemicals or treated materials may fall under UK REACH regulations. Importers must ensure that restricted substances are not present above permitted thresholds.

Intellectual Property Protection

Counterfeit automotive parts are a known risk. Importing branded components without authorization can lead to seizure at customs and legal penalties. Supplier due diligence is essential.

Customs Classification and Duties

Automotive parts must be correctly classified under the UK Global Tariff using the appropriate HS code. Incorrect classification can lead to delays, penalties, or unexpected duty charges.

Working with an experienced trade partner helps reduce regulatory risks and ensures documentation is complete before shipment.

Supplier Verification and Quality Control

One of the most important steps in automotive parts import from China to UK is selecting the right supplier. While many Chinese manufacturers operate to international standards, quality can vary significantly between suppliers.

Importers should conduct:

-

Factory audits or third-party inspections

-

Sample testing prior to bulk production

-

Verification of certifications and export licenses

-

Clear technical specification agreements

Quality control inspections at the pre-shipment stage help prevent defective or non-compliant parts from entering the UK market. This is particularly important for safety-critical components, where failure can damage brand reputation and lead to liability issues.

Wigmore Trading supports businesses by identifying reliable suppliers, coordinating inspections, and ensuring production aligns with UK market requirements.

Shipping and Logistics Considerations

Shipping automotive parts from China to the UK requires careful planning. The choice between sea freight, air freight, or rail depends on product type, urgency, and budget.

Sea freight is generally the most cost-effective option for bulk shipments, especially heavy components such as suspension systems or engine parts. Air freight may be appropriate for urgent or high-value electronic components but significantly increases costs.

Importers must also decide on Incoterms. Many suppliers quote on FOB (Free on Board) terms, but businesses should clearly understand where responsibility and risk transfer.

Additional logistics considerations include:

-

Proper packaging to prevent damage during transit

-

Cargo insurance coverage

-

Port congestion and seasonal delays

-

Post-Brexit customs procedures

Wigmore Trading helps coordinate freight forwarding, manage customs documentation, and streamline clearance processes to minimise delays and unexpected costs.

Customs Clearance and Documentation

Accurate documentation is essential when importing automotive parts into the UK. Missing or incorrect paperwork can result in shipment holds or penalties.

Typical documentation includes:

-

Commercial invoice

-

Packing list

-

Bill of lading or airway bill

-

Certificate of origin (if required)

-

Conformity or compliance documentation

UK importers must hold an EORI number and ensure VAT and duty payments are correctly declared. Businesses may also benefit from postponed VAT accounting to improve cash flow.

Partnering with a knowledgeable logistics and trade specialist reduces the administrative burden and ensures compliance with evolving customs regulations.

Managing Risks in Automotive Parts Import from China to UK

While importing offers cost advantages, businesses should plan for potential risks:

Supply Chain Disruption

Global shipping volatility can affect transit times and freight costs. Diversifying suppliers or maintaining safety stock can mitigate disruption.

Quality Variability

Inconsistent quality can lead to warranty claims or customer dissatisfaction. Clear specifications and inspection protocols reduce this risk.

Currency Fluctuation

Exchange rate movements between GBP and RMB can affect margins. Forward contracts or pricing agreements can help manage exposure.

Regulatory Changes

UK trade and safety regulations continue to evolve. Staying informed is critical for long-term compliance.

An experienced trade partner provides visibility across sourcing, compliance, and logistics, helping businesses navigate these challenges efficiently.

Building a Sustainable Import Strategy

Automotive parts import from China to UK should not be treated as a one-off transaction. Long-term success depends on building structured supplier relationships, maintaining quality standards, and creating resilient logistics systems.

Businesses that invest in due diligence, compliance management, and transparent supply chain processes are better positioned to compete in the UK aftermarket and distribution sectors.

Wigmore Trading works with importers, wholesalers, and distributors to simplify international sourcing. From supplier identification and quality control to freight coordination and customs clearance, the right support ensures smoother operations and reduced risk.

Conclusion

Automotive parts import from China to UK presents significant opportunities for cost savings and product diversification. However, successful importing requires more than competitive pricing. It demands careful supplier selection, strict regulatory compliance, efficient logistics planning, and proactive risk management.

With the right processes in place, UK businesses can build reliable supply chains that support growth and maintain high product standards.

Wigmore Trading can help. Contact Wigmore Trading today to streamline your sourcing.

Comments are closed.