Ethylene Oxide Manufacturers: How to Source Safely and Reliably for Industrial Use

Ethylene oxide (EO) is one of the world’s most important chemical intermediates, used to produce thousands of downstream products across manufacturing, FMCG, pharmaceuticals, textiles, packaging, and industrial processing. If your business depends on ethylene glycol, surfactants, detergents, or specialty chemicals, then your supply chain is indirectly tied to ethylene oxide producers.

However, sourcing ethylene oxide is not as simple as buying a standard commodity chemical. EO is highly flammable, toxic, and tightly regulated, which makes supplier selection, compliance, and logistics critical. In this guide, we explain how ethylene oxide is produced, who the major ethylene oxide manufacturers are, and what buyers in Africa and global trade markets should consider when sourcing EO-based products.

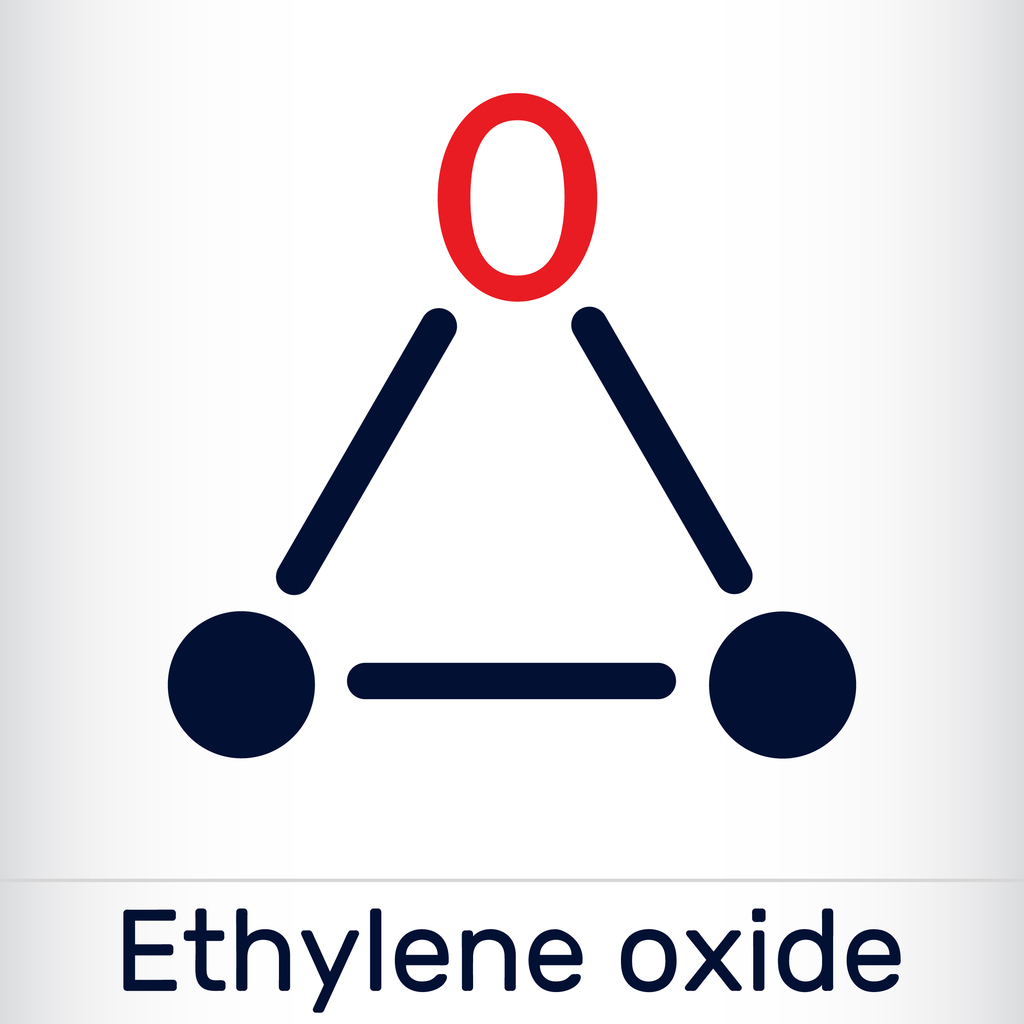

What Is Ethylene Oxide (EO)?

Ethylene oxide is a reactive organic compound mainly produced via the direct catalytic oxidation of ethylene, typically using silver-based catalysts in industrial reactors. This is the dominant commercial process because it is efficient and scalable for mass production.

EO is rarely consumed directly by end-users. Instead, it is converted into derivatives such as:

-

Ethylene glycol (antifreeze, polyester, PET plastics)

-

Ethoxylates and surfactants (detergents, cosmetics, industrial cleaners)

-

Ethanolamines (gas treatment, agrochemicals, personal care products)

-

Sterilants, especially for medical device sterilization applications

Industry estimates show that most EO is used to produce ethylene glycols, making EO essential to polyester and packaging supply chains.

Why Ethylene Oxide Supply Is Highly Sensitive

Ethylene oxide requires strict handling because health and environmental agencies classify it as hazardous. Many authorities identify EO as a substance that must be handled with strong exposure controls due to its health risks.

Because of these risks, EO production and distribution involve significant regulation, specialized packaging requirements, and strict import/export documentation. This affects availability, shipping lead times, and price stability.

Leading Ethylene Oxide Manufacturers (Global Producers)

Ethylene oxide is produced mainly by large integrated petrochemical companies that have access to ethylene feedstock and downstream conversion capacity. Some of the best-known global producers include:

-

Dow

-

BASF

-

Shell

-

SABIC

-

Sinopec (China Petrochemical Corporation)

These manufacturers typically operate EO plants within broader petrochemical complexes, producing both EO and its derivatives (especially ethylene glycol and glycol ethers).

Why this matters for African importers and industrial buyers

Most EO buyers in Africa don’t import ethylene oxide directly due to transport restrictions. Instead, they import EO derivatives such as:

-

Monoethylene glycol (MEG)

-

Diethylene glycol (DEG)

-

Ethoxylates

-

Industrial surfactants

-

Ethanolamines

That means your supply stability depends not only on EO producers, but also on traders and distributors who can source from multiple global plants and manage compliant shipping.

How to Choose the Right Ethylene Oxide Supplier or Distributor

Whether you buy ethylene oxide derivatives for manufacturing or distribution, supplier qualification is key. Here’s what to evaluate:

1. Product purity and specification

EO derivatives are used in sensitive applications (textiles, pharmaceuticals, cleaning products, packaging). Choose suppliers that provide:

-

COA (Certificate of Analysis)

-

SDS (Safety Data Sheet)

-

Clear spec sheets and consistent batch quality

2. Regulatory compliance

Because EO is hazardous, compliance is essential. Your supplier should support:

-

Proper HS codes and export/import papers

-

IMDG/ADR handling for sea/road freight (for regulated cargo where required)

-

Documentation aligned with local requirements

3. Supply reliability and diversification

Supply disruptions happen due to plant maintenance, regional closures, or capacity changes—especially in Europe and Asia’s petrochemical sector.

Working with a sourcing partner that can pull from multiple regions helps reduce risk.

4. Logistics capability into Africa

Many EO derivatives need careful storage, temperature control, and safe warehousing. A strong supplier should offer:

-

Bulk or drum/container options

-

Consolidation services

-

Port-to-door logistics support

-

Support for customs clearance (especially in West Africa)

Common Challenges When Importing EO-Based Chemicals Into Africa

Importers and manufacturers in Nigeria, Ghana, Kenya, South Africa, and other African markets often face:

-

Delays in documentation approval

-

Limited availability of compliant shipping lanes

-

Higher freight costs for regulated chemicals

-

Inconsistent quality from non-verified sources

Practical solutions

To avoid these issues:

- Buy from established producers or verified distributors

- Work with sourcing partners experienced in Africa-bound shipments

- Ensure paperwork is ready before shipment leaves origin

- Build buffer stock for essential inputs like MEG or surfactants

This is where Wigmore Trading can help—by sourcing ethylene oxide derivatives from reputable global supply networks and supporting logistics and compliance for African importers.

How Wigmore Trading Supports EO-Based Chemical Sourcing

Wigmore Trading works with manufacturers, wholesalers, and industrial buyers to source essential petrochemical inputs, including EO derivatives used in:

-

FMCG manufacturing (detergents, cleaners, cosmetics)

-

Textile and packaging industries

-

Industrial chemicals distribution

-

Food-grade and pharmaceutical supply chains (where applicable)

By combining procurement expertise with logistics support, Wigmore Trading can help streamline sourcing and reduce supply disruptions—especially for African markets where compliant chemical importation can be complex.

Contact Wigmore Trading today to streamline your sourcing and get reliable access to ethylene oxide-based industrial chemicals.

Comments are closed.