Ethylene Oxide SDS: Safety, Handling, and Compliance in Trade

Ethylene oxide is a widely used industrial chemical, particularly in sterilization, pharmaceuticals, FMCG manufacturing, and chemical processing. Because it is classified as hazardous, having a clear and accurate ethylene oxide SDS (Safety Data Sheet) is essential for businesses involved in importing, exporting, storing, or using this substance. For companies operating across African and international supply chains, compliance is not optional—it is critical for safety, legal approval, and smooth logistics.

Wigmore Trading supports businesses by sourcing compliant chemicals, facilitating documentation, and ensuring regulatory alignment across borders.

What Is an Ethylene Oxide SDS?

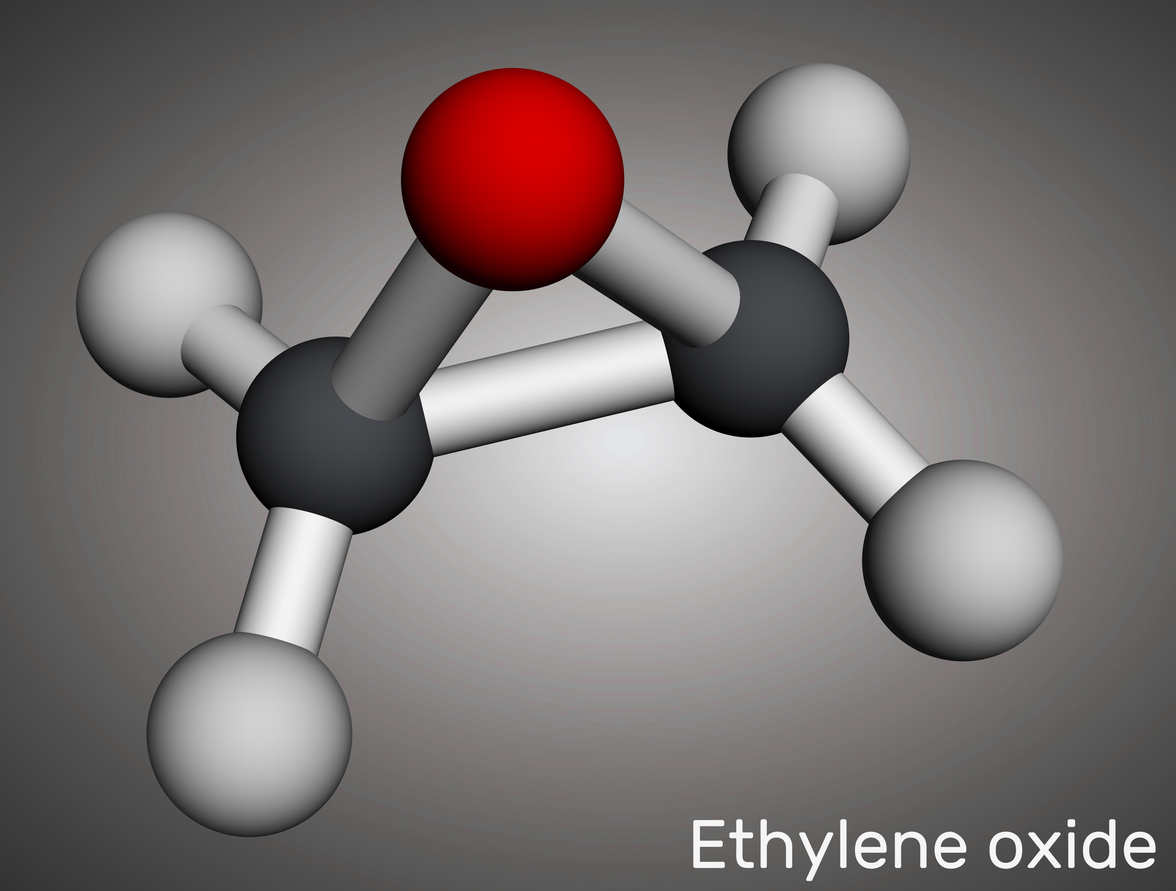

An ethylene oxide SDS is an official document that outlines the chemical’s properties, hazards, safe handling procedures, and emergency measures. It is required by regulators, customs authorities, logistics providers, and workplace safety agencies.

A standard ethylene oxide SDS includes:

-

Chemical identification and composition

-

Hazard classification (flammable, toxic, carcinogenic)

-

Handling and storage guidelines

-

Exposure controls and personal protective equipment (PPE)

-

Transport and disposal instructions

For importers and distributors, an up-to-date SDS ensures shipments are not delayed or rejected due to non-compliance.

Why Ethylene Oxide SDS Compliance Matters

Ethylene oxide is highly flammable and poses health risks if mishandled. Regulatory bodies such as OSHA, REACH, and GHS require strict documentation and labeling.

Without a valid ethylene oxide SDS, businesses may face:

-

Shipment holds at ports

-

Regulatory penalties or fines

-

Increased workplace accident risks

-

Loss of insurance or supplier approvals

Wigmore Trading can help businesses source ethylene oxide with the correct SDS documentation, reducing compliance risks throughout the supply chain.

Safe Handling and Storage Guidelines

According to most ethylene oxide SDS documents, safe handling requires:

-

Storage in cool, well-ventilated areas

-

Explosion-proof equipment and grounding

-

Continuous monitoring for leaks or exposure

-

Use of certified PPE such as gloves and respirators

For African markets where infrastructure standards vary, these requirements are especially important. Wigmore Trading works with trusted suppliers and logistics partners to ensure safe packaging, transport, and storage conditions that meet international standards.

Ethylene Oxide SDS for Import and Export Operations

When trading ethylene oxide across borders, the SDS plays a key role in:

-

Customs clearance

-

Freight forwarding approval

-

Warehouse acceptance

-

Regulatory inspections

Different countries may require localized SDS formats or language translations. Wigmore Trading helps businesses navigate these variations, ensuring that ethylene oxide SDS documents align with destination-country regulations and international trade requirements.

Common Challenges with Ethylene Oxide SDS Documentation

Many importers face issues such as:

-

Outdated SDS versions

-

Incomplete hazard classifications

-

Non-GHS-compliant formatting

-

Mismatch between SDS and shipping labels

These issues can disrupt supply chains and increase costs. Wigmore Trading can help by coordinating with manufacturers, verifying documentation accuracy, and ensuring consistency across invoices, packing lists, and SDS files.

How Wigmore Trading Supports Ethylene Oxide Sourcing

Wigmore Trading supports chemical buyers, distributors, and manufacturers by:

-

Sourcing ethylene oxide from reputable suppliers

-

Providing accurate, compliant ethylene oxide SDS documentation

-

Supporting safe logistics and cross-border compliance

-

Assisting FMCG, pharmaceutical, and industrial clients across Africa

Rather than navigating regulatory complexity alone, businesses can rely on Wigmore Trading’s experience in chemical sourcing and trade facilitation.

Final Thoughts

An accurate and compliant ethylene oxide SDS is essential for safety, regulatory approval, and efficient trade operations. From handling and storage to customs clearance, the SDS underpins every stage of the supply chain. Wigmore Trading can help businesses reduce risk, maintain compliance, and streamline chemical sourcing across African and global markets.

Contact Wigmore Trading today to streamline your sourcing and compliance process.

Comments are closed.