Exploring the Benefits of Polyurethane Raw in Various Industries

Exploring the Benefits of Polyurethane Raw in Various Industries

Are you curious about the extraordinary capabilities of polyurethane raw material? Look no further! In today’s blog post, we will delve into the fascinating world of this versatile substance and uncover its countless benefits across a multitude of industries. From enhancing product durability to revolutionizing manufacturing processes, join us as we embark on an exploration of how polyurethane raw material is making waves in various sectors. Get ready to be amazed by the endless possibilities that lie within this remarkable compound – it’s time to discover why polyurethane is taking industries by storm!

Introduction to Polyurethane Raw

Polyurethane raw materials are highly versatile and widely used in various industries, from construction to automotive to furniture manufacturing. It is a synthetic material that has been developed over the years to meet the growing demand for durable, high-performance materials.

In simple terms, polyurethane raw is a polymer composed of organic units joined by carbamate (urethane) links. It can be produced in different forms such as liquid, foam, or solid depending on its intended use. This flexibility makes it an ideal choice for many applications as it can be customized to meet specific requirements.

One of the key benefits of using polyurethane raw is its exceptional strength and durability. It has a strong molecular structure that makes it resistant to wear and tear, making it suitable for high-traffic areas and heavy-duty applications. This strength also makes it an excellent alternative to traditional materials like wood or metal as it can withstand harsh weather conditions and extreme temperatures.

Another advantage of polyurethane raw is its versatility in terms of physical properties. By adjusting the formulation during production, manufacturers can create different types of polyurethane with varying levels of hardness, elasticity, density, and other characteristics. This allows them to cater to a wide range of industries and applications – from soft foams used in mattresses and cushions to hard plastics used in automotive parts.

What is Polyurethane?

Polyurethane is a versatile polymer that has gained immense popularity in various industries due to its numerous benefits and applications. It is a type of plastic that can be either rigid or flexible, depending on how it is formulated. The chemical reaction between polyols and diisocyanates forms this synthetic resin, which can then be molded into different shapes and forms.

One of the most notable properties of polyurethane is its exceptional strength and durability. This makes it an ideal material for applications where toughness and resistance to wear are essential, such as in the construction industry. Polyurethane raw materials are used in producing coatings, adhesives, sealants, and foam products for building insulation, flooring, roofing, pipes, and more.

Apart from its robustness, polyurethane also offers excellent thermal insulation properties. It has a low thermal conductivity rate compared to other materials like wood or metal, making it an efficient choice for insulating homes and commercial buildings. This energy-saving feature not only reduces heating costs but also minimizes environmental impact by lowering carbon emissions.

In addition to being strong and thermally efficient, another significant advantage of using polyurethane raw materials is their flexibility. Polyurethane can be molded into various shapes without breaking or losing its original form. This unique characteristic makes it highly suitable for manufacturing customizable products such as automobile parts, furniture cushions, and medical equipment.

The Manufacturing Process of Polyurethane Raw

Polyurethane raw materials are essential components in the production of a wide range of products, from insulation materials to car parts. This versatile material has become increasingly popular in various industries due to its unique properties and benefits. But have you ever wondered how this material is created? In this section, we will take a closer look at the manufacturing process of polyurethane raw materials.

1. Obtaining Raw Materials

The first step in the manufacturing process of polyurethane raw is obtaining the necessary ingredients. The two main components are polyols and diisocyanates, which are derived from crude oil or natural gas. Other additives such as blowing agents, cross-linkers, and catalysts may also be needed depending on the specific type of polyurethane being produced.

2. Blending Polyols and Diisocyanates

Once all the necessary raw materials are obtained, they are then blended together using specialized mixing equipment under strict temperature and pressure conditions. This process is known as polymerization and results in a liquid form known as a prepolymer.

3. Adding Additives

Next, additional additives such as blowing agents or catalysts may be added to enhance specific properties of the polyurethane raw material. For example, blowing agents help create foam while catalysts control the rate of curing.

Properties and Characteristics of Polyurethane Raw

Properties and Characteristics of Polyurethane Raw:

Polyurethane raw materials are versatile compounds that have been used in a wide range of industries for years. They offer unique properties and characteristics that make them highly desirable for various applications. In this section, we will explore the key features and advantages of polyurethane raw materials.

1. Strong and Durable:

One of the most notable properties of polyurethane raw is its strength and durability. The chemical structure of polyurethane allows it to withstand high levels of stress, making it ideal for applications that require heavy-duty performance. It can resist impacts, abrasion, and wear, making it suitable for use in harsh environments.

2. Flexibility:

Polyurethane raw has exceptional flexibility, which makes it an excellent choice for applications where movement or bending is required. It can easily be molded into different shapes without losing its strength or structural integrity. This property also makes it an ideal material for cushioning and shock absorption purposes.

3. Chemical Resistance:

Polyurethane raw has excellent resistance to chemicals such as oils, solvents, acids, and alkalis. This property makes it highly suitable for use in industries where exposure to these substances is common, such as automotive manufacturing or food processing.

4. Thermal Insulation:

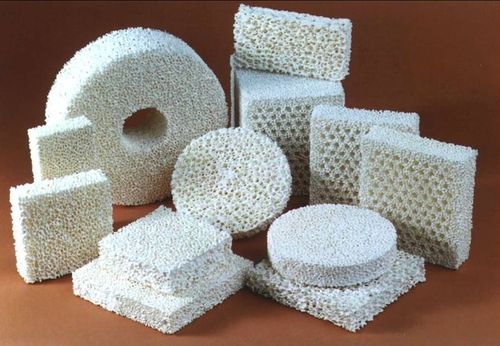

The cellular structure of polyurethane raw provides excellent thermal insulation properties. It has a low thermal conductivity which means it can effectively prevent heat transfer between two surfaces, making it an ideal material for insulation purposes.

Applications of Polyurethane Raw in Different Industries

Polyurethane raw material is a versatile and highly durable substance that has become increasingly popular in various industries. Its unique properties make it suitable for a wide range of applications, from household products to heavy-duty industrial use. In this section, we will explore the numerous ways polyurethane raw material is utilized in different industries.

1. Construction Industry:

One of the main uses of polyurethane raw material in the construction industry is as insulation for buildings. Polyurethane foam can be sprayed or injected into walls, roofs, and floors, providing excellent thermal insulation and preventing air leakage. This helps to reduce energy costs and make buildings more environmentally friendly.

Polyurethane coatings are also widely used in construction projects due to their resistance to water, chemicals, and extreme temperatures. They provide a protective layer on surfaces such as concrete, wood, metal, and even roofing materials. This makes them ideal for roofing systems, waterproofing basements or tanks, protecting bridges and other structures from corrosion.

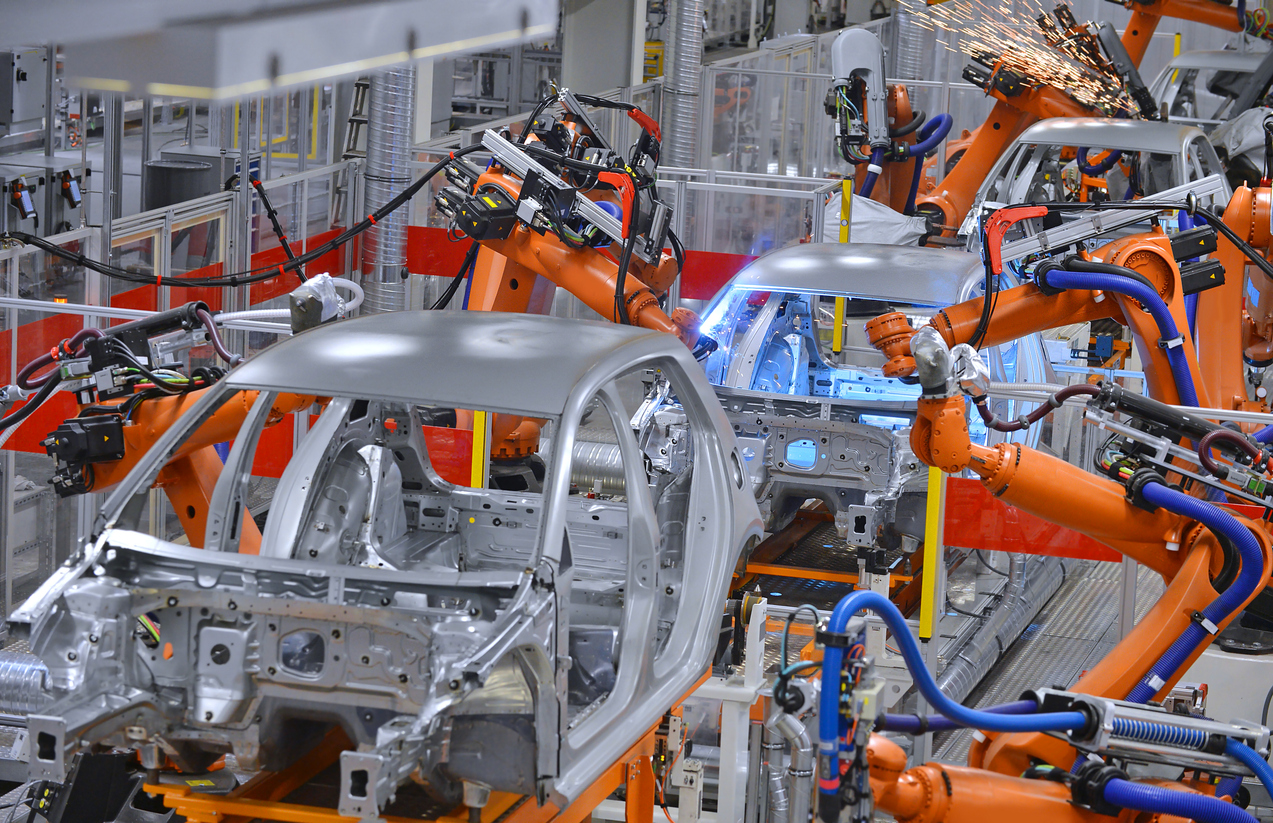

2. Automotive Industry:

The automotive industry has been using polyurethane raw material for decades due to its lightweight yet strong nature. It is commonly used in car interiors for seats, dashboards, armrests because it provides comfort and durability while being resistant to stains and wear-and-tear.

– Automotive

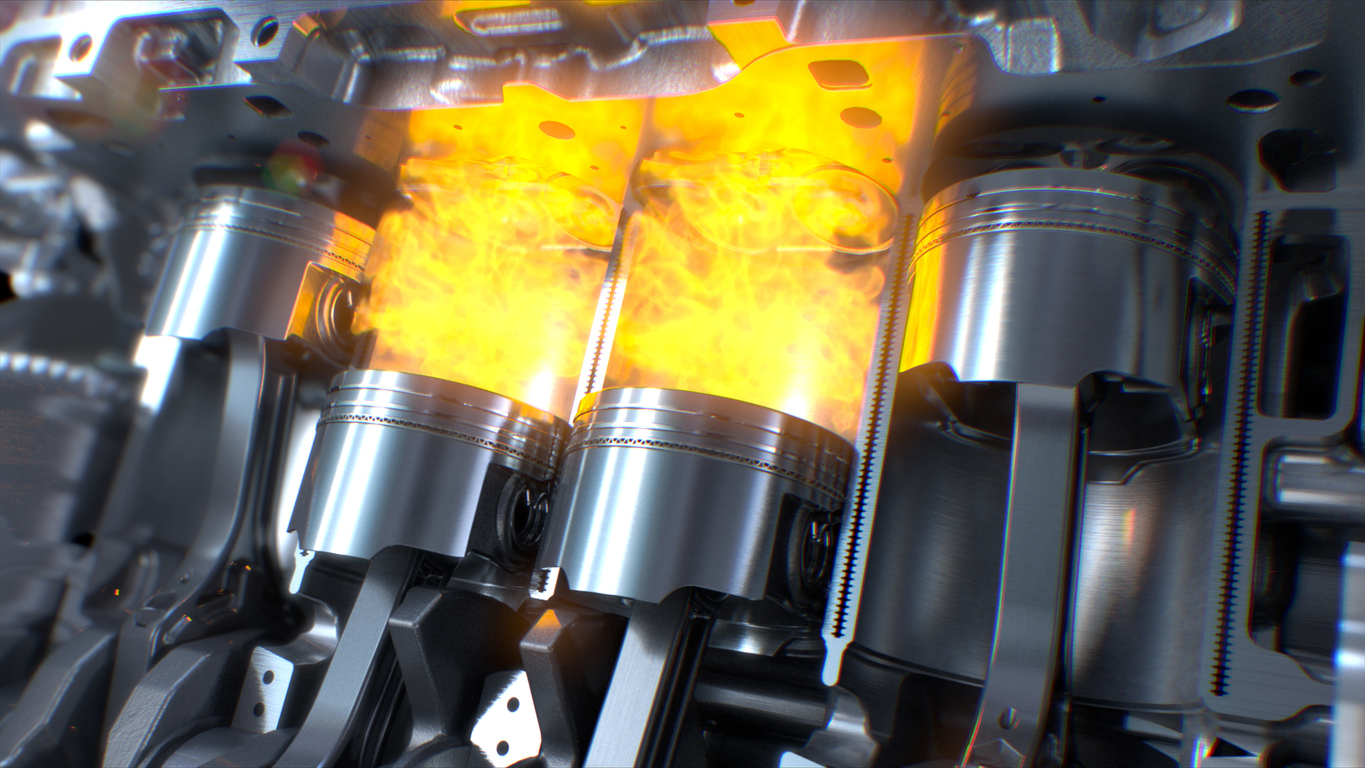

Automotive industry is one of the major industries that heavily rely on polyurethane raw materials for a wide range of applications. From manufacturing to repair and maintenance, polyurethane has been proven to be an essential component in the production of high-quality vehicles.

One of the primary uses of polyurethane in the automotive industry is in the production of car parts. Polyurethane foam, with its lightweight and durable properties, is widely used in the manufacturing of car seats, headrests, armrests and other interior components. This not only adds to the comfort of passengers but also helps reduce overall vehicle weight, improving fuel efficiency.

In addition to interior components, polyurethane is also utilized in making exterior parts such as bumpers, spoilers and body panels. Its impact resistance and ability to withstand extreme weather conditions make it a preferred choice for these applications. Furthermore, using polyurethane instead of traditional metal or plastic materials reduces vehicle weight which results in better handling and improved performance.

Another important use of polyurethane in automobiles is for sealing applications. The material’s excellent sealing properties make it ideal for creating gaskets that can effectively prevent leaks from occurring between different engine parts such as valves, pumps and cylinders. This ensures smooth operation and extends engine life.

– Construction

Polyurethane, a versatile material with a wide range of applications, is becoming increasingly popular in various industries. One of the key reasons behind its popularity is its use in construction. In this section, we will explore the benefits of polyurethane raw materials in the construction industry.

1. Durability and Strength:

One of the primary advantages of using polyurethane raw materials in construction is its exceptional durability and strength. Polyurethane has high tensile strength and can withstand heavy loads without cracking or breaking. This makes it an ideal choice for building foundations, structural supports, and even roofing materials.

2. Lightweight:

Despite its incredible strength, polyurethane is surprisingly lightweight compared to other building materials such as concrete or steel. Its light weight makes it easier to handle during the construction process, reducing labor costs and time significantly.

3. Versatility:

Polyurethane raw material can be molded into any shape or form, making it highly versatile for construction purposes. It can be used to create intricate designs and patterns that would be difficult to achieve with other materials like wood or metal.

4. Thermal Insulation:

Polyurethane has excellent thermal insulation properties which make it a popular choice for building insulation. It helps regulate temperature inside buildings by preventing heat loss during winters and keeping interiors cool during summers. This results in reduced energy consumption and cost savings on heating/cooling bills.

– Furniture

Furniture has been an integral part of human civilization for centuries, with its use dating back to ancient times. Over the years, furniture has evolved from being simple and functional to becoming a statement piece in interior design. With the advancements in technology and materials, furniture production has also seen significant changes. One such material that has revolutionized the furniture industry is polyurethane raw.

Polyurethane raw, or simply PU raw, is a versatile polymer that can be molded into different shapes and forms, making it a perfect choice for furniture production. It offers numerous benefits over other materials commonly used in the industry, such as wood and plastic. Let’s explore some of the key advantages of using polyurethane raw in furniture manufacturing.

1. Durability:

One of the primary benefits of using polyurethane raw in furniture production is its durability. Unlike traditional materials like wood or plastic, which are susceptible to wear and tear over time, PU raw is highly resistant to scratches, dents, and stains. This makes it an ideal option for high-traffic areas such as offices or homes with children and pets.

2. Versatility:

PU raw can be easily molded into any shape or design without compromising its strength or quality. This means that designers have endless possibilities when it comes to creating unique and innovative pieces of furniture with polyurethane raw. From modern and sleek designs to intricate patterns and textures, this material allows for maximum customization options.

– Packaging

Packaging plays a crucial role in the transportation and storage of goods, ensuring their protection from damage and contamination. With the rise of e-commerce and global trade, the demand for efficient and durable packaging solutions has increased significantly. This is where polyurethane raw materials come into play.

Polyurethane (PU) is a versatile polymer that can be molded into various forms, making it an ideal material for packaging applications. It offers several benefits over traditional packaging materials like paper, cardboard, or plastic. Let’s delve deeper into how PU raw materials are revolutionizing the packaging industry across different sectors.

1. Lightweight yet Durable Packaging:

One of the primary advantages of using PU in packaging is its lightweight nature combined with exceptional strength. Compared to traditional materials like wood or metal, PU foam-based packages are significantly lighter while providing the same level of structural integrity. This makes them easier and more cost-effective to transport and handle.

Moreover, polyurethane foam also has excellent shock-absorbing properties, making it suitable for fragile items such as electronics or glassware. Its high resilience ensures that even if there is an impact during transit, the product inside remains safe from any damage.

2. Customizable Solutions:

PU can be easily molded into different shapes and sizes, allowing manufacturers to create custom-made packages based on their specific requirements. Whether it’s a small delicate item or a large industrial component, PU can be tailored to fit any shape without compromising on its durability.

– Footwear and Apparel

Polyurethane is a versatile material that has found its way into various industries, including footwear and apparel. This synthetic polymer offers a wide range of benefits that make it the go-to choice for manufacturers in these industries. From improved performance to enhanced comfort, polyurethane raw has revolutionized the production of footwear and apparel.

One of the primary advantages of using polyurethane raw in footwear and apparel is its durability. Polyurethane is known for its strong molecular structure, making it highly resistant to wear and tear. This means that products made from this material can withstand prolonged use without losing their shape or quality. In the case of footwear, this translates to longer-lasting shoes that can withstand different terrains and weather conditions.

Additionally, polyurethane raw offers excellent flexibility, which is crucial in both footwear and apparel design. This material can be molded into various shapes without compromising its strength, allowing manufacturers to create innovative designs that are both functional and aesthetically appealing. Shoes made with polyurethane soles provide better traction and stability, making them suitable for sports activities or everyday wear.

Another significant benefit of using polyurethane raw in footwear and apparel is its lightweight nature. Compared to other materials like rubber or leather, polyurethane weighs significantly less while still maintaining its strength. This makes it an ideal choice for athletic shoes where weight matters when it comes to performance.

Advantages of Using Polyurethane Raw

Polyurethane raw, also known as polyol and isocyanate, is a versatile material that has become increasingly popular in various industries. This type of raw material is used in the production of a wide range of products such as furniture, automotive parts, and insulation materials. In this section, we will explore the numerous advantages that using polyurethane raw can bring to different industries.

1. Lightweight yet Durable:

One of the main advantages of using polyurethane raw is its lightweight nature while still providing exceptional durability. This makes it an ideal material for applications where weight is a crucial factor such as in the automotive industry or for portable equipment. Despite being lightweight, polyurethane has high tensile strength and can withstand heavy loads without cracking or breaking.

2. Versatile:

Another significant advantage of using polyurethane raw is its versatility. Polyurethane can be tailored to meet specific requirements by adjusting its chemical composition during the manufacturing process. This allows for the production of different types and grades of polyurethane suitable for various applications. Whether it’s soft and flexible or rigid and tough, there’s a type of polyurethane to suit every need.

3. Excellent Insulation Properties:

Polyurethane raw has excellent thermal insulation properties, making it an ideal choice for insulating buildings, refrigeration units, and pipes. Its low thermal conductivity helps reduce heat loss or gain depending on the application, resulting in energy savings and improved efficiency.

Challenges and Solutions in Working with Polyurethane Raw

Polyurethane raw materials have become increasingly popular in various industries due to their versatility, durability, and cost-effectiveness. However, working with polyurethane raw materials can also present some challenges that need to be addressed for successful use and application. In this section, we will discuss the common challenges faced when working with polyurethane raw materials and explore possible solutions to overcome them.

1. Handling Hazardous Materials:

Polyurethane raw materials are hazardous substances that require careful handling to ensure the safety of workers. The liquid components of polyurethane contain isocyanates, which can cause skin irritation and respiratory problems if proper precautions are not taken. Moreover, these chemicals may emit harmful vapors during the curing process.

Solution: To address this challenge, it is essential to follow strict safety protocols while handling polyurethane raw materials. These may include wearing protective gear such as gloves, goggles, and masks when working with the material. Additionally, providing proper ventilation in workspaces can help minimize exposure to harmful fumes.

2. Short Pot Life:

Pot life refers to the time duration during which a material remains usable after mixing its components together. One major challenge faced when working with polyurethane raw materials is their short pot life compared to other resins or adhesives.

Environmental Impact of Polyurethane Raw

Polyurethane raw materials have gained widespread use in various industries due to their versatile properties, but it is important to consider the environmental impact of using these materials. The production and usage of polyurethane raw can have both positive and negative effects on the environment, which need to be carefully evaluated.

One of the main concerns when it comes to the environmental impact of polyurethane raw is its manufacturing process. Polyurethane is typically produced through a chemical reaction between two components – a diisocyanate compound and a polyol compound. This process requires high energy consumption and emits greenhouse gases, contributing to air pollution and climate change. In addition, the production process also generates hazardous byproducts such as volatile organic compounds (VOCs) which can harm human health and ecosystems.

Another major concern with polyurethane raw materials is their disposal at the end of their lifespan. Polyurethane products are not easily biodegradable and therefore pose a threat to landfills where they take up valuable space for hundreds of years. Incineration of these products also releases toxic fumes into the atmosphere, further contributing to air pollution.

However, despite these negative impacts, there are also several positive environmental aspects related to polyurethane raw materials. One notable benefit is its durability – products made from this material have longer lifespans compared to other alternatives such as wood or metal. This means that they do not need frequent replacement, reducing waste generation in the long run.

Comments are closed.