From Mine to Market: Understanding the Supply Chain of Jamaican Aluminium Ore

From Mine to Market: Understanding the Supply Chain of Jamaican Aluminium Ore

Jamaica, known for its vibrant culture, stunning beaches, and reggae music, has long been a source of fascination. However, there is much more to this Caribbean island than meets the eye. Deep within its lush landscapes lies a hidden treasure – aluminium ore. But have you ever wondered what goes on behind the scenes before that shiny metal finds its way into your everyday life? Join us as we embark on an enlightening journey through the supply chain of Jamaican aluminium ore – from mine to market. Get ready to uncover the secrets of this fascinating industry and gain a newfound appreciation for the incredible efforts involved in bringing this valuable resource from Jamaica’s soil to global markets.

Introduction to Jamaican Aluminium Ore

The Jamaican aluminium ore supply chain is a long and complicated one. It starts with the mining of bauxite in the country’s interior, which is then transported to alumina refineries where it is processed into alumina. The alumina is then shipped to aluminium smelters around the world where it is made into aluminium metal.

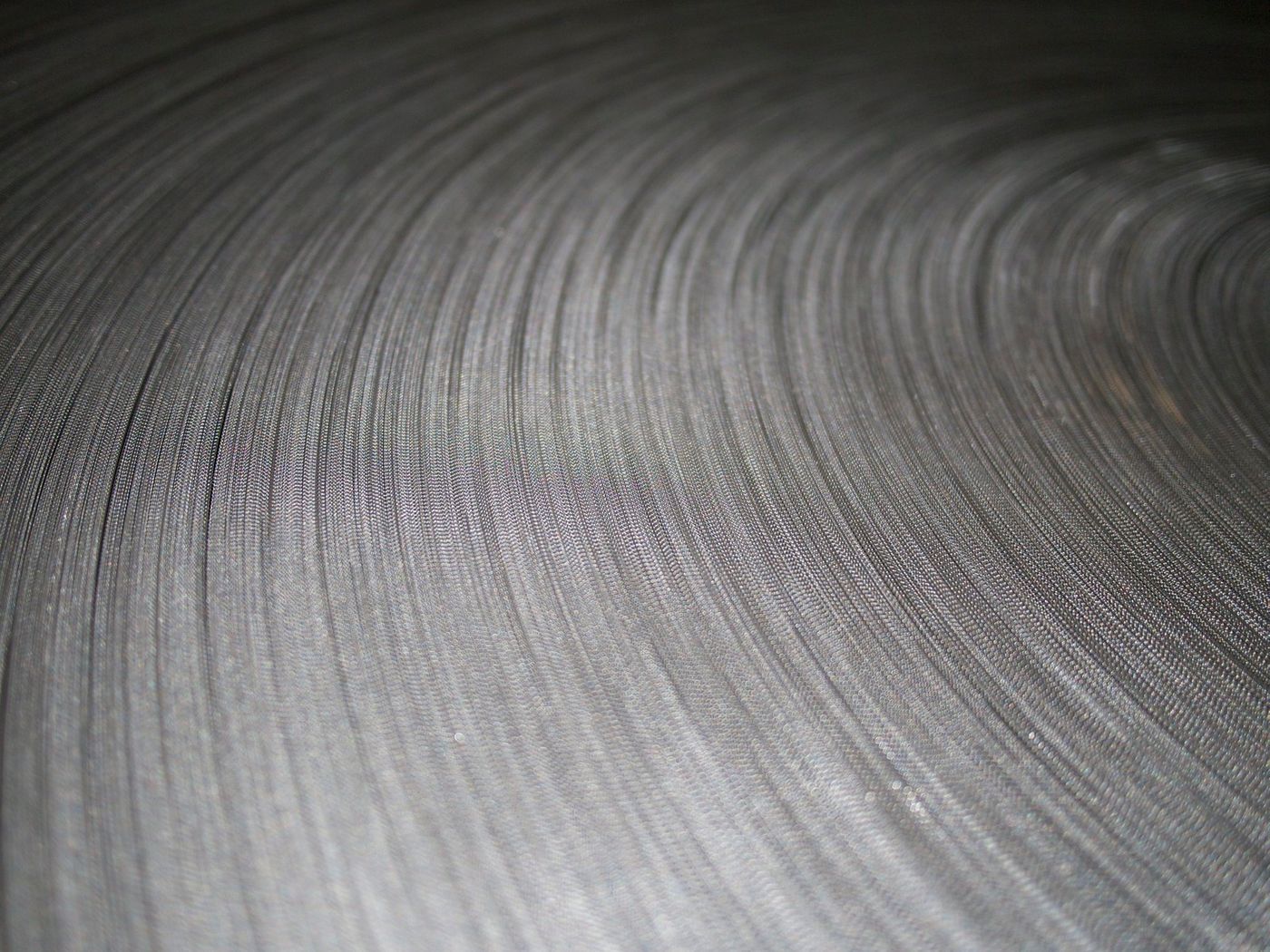

Jamaica has been producing bauxite since the 1940s, and today it is one of the world’s leading producers of the ore. The country has a number of large bauxite mines, most notably in the parishes of St. Ann and Manchester. Mining operations are typically conducted by open-pit methods, with heavy machinery stripping away the overburden to expose the underlying bauxite deposits.

Once mined, the bauxite is transported to an alumina refinery where it is processed into alumina (aluminium oxide). Jamaica has two major alumina refineries, both located in Clarendon Parish. One refinery is operated by Jamalco, a joint venture between Alcoa and the Government of Jamaica, while the other is operated by Alumina Partners of Jamaica (APJ).

After processing, the alumina is shipped out of Jamaica to aluminium smelters around the world where it is made into aluminium metal. Jamaica does not have its own aluminium smelter so all of its alumina must be exported for processing. The majority of Jamaican alumina ends up going to smel

Mining and Processing of Aluminium Ore in Jamaica

Jamaica is rich in bauxite, the ore from which aluminium is extracted. Bauxite mining and processing is a complex and energy-intensive process, which requires significant investment in infrastructure and technology. The Jamaican government has been working to attract foreign investment in the bauxite sector and to develop the country’s mining and processing capabilities.

Jamaica’s bauxite resources are estimated at 2.7 billion tonnes, making it one of the largest reserves of the mineral in the world. The island has a long history of bauxite mining, dating back to the early 20th century when production first began on a small scale. Jamaica’s bauxite deposits are relatively high quality, with low levels of impurities such as silica and iron oxide. This makes Jamaican bauxite ideal for use in alumina refineries, which convert the bauxite into alumina, the feedstock for aluminium smelters.

There are currently two active bauxite mines in Jamaica, both of which are owned by international companies. Noranda Aluminum Holding Corporation operates the St. Ann mine, while Century Aluminum Company owns and operates the Ewarton mine. Noranda is also constructing a new port facility at Port Rhoades, which will be used to ship bauxite from its mines to export markets.

Jamaica’s alumina refineries are located at Jamalco, which is jointly owned by Noble Group and Clarendon Al

Transporting Aluminium Ore from Mine to Market

Transporting aluminium ore from mine to market is a complex process that involves a number of steps. The first step is to extract the ore from the ground. This is typically done using large machines such as excavators or bulldozers. Once the ore has been extracted, it needs to be transported to a processing plant. This can be done by rail, road, or sea.

The next step is to process the ore at the plant. This involves crushing the ore and separating out the aluminium metal. The metal is then smelted and cast into ingots or rods. These ingots or rods are then transported to factories where they are used to produce aluminium products.

The final step in the process is to get the aluminium products to consumers. This can be done through a number of channels including retailers, wholesalers, and online stores.

Regulations Governing the Export of Aluminium Ore from Jamaica

The Ministry of Transport and Mining in Jamaica has put in place a number of regulations to govern the export of aluminium ore from the country. These include a requirement for all exports to be declared to the ministry, as well as a number of other documentation requirements.

In addition, the ministry has also put in place a system of quotas for exports, which are based on the amount of ore mined in Jamaica each year. This is to ensure that the country does not become reliant on exports of aluminium ore, and to ensure that there is enough ore available for domestic use.

Benefits of Exporting Jamaican Aluminium Ore

Aluminium ore is an important export commodity for Jamaica. The country has a long history of mining and exporting aluminium ore, dating back to the early 20th century. Today, Jamaican aluminium ore is still exported to countries all over the world, providing a valuable source of income for the country.

Aluminium ore is used in a variety of industries, including the automotive and construction industries. It is also used in the production of a number of consumer goods, such as aluminium cans and foil. Exporting Jamaican aluminium ore provides many benefits for the country, including:

1. generating foreign currency revenue;

2. supporting the local mining industry;

3. creating jobs; and

4. contributing to economic growth.

Challenges of Exporting Jamaican Aluminium Ore

The high cost of energy is one of the main challenges facing Jamaican aluminium ore exporters. The country has to import all of its oil and gas, which makes energy very expensive. This increases the cost of producing aluminium ore and makes it difficult for Jamaican companies to compete with other countries in the global market.

Jamaica also lacks the infrastructure needed to support a large-scale mining operation. There are no deep-sea ports or railroads, which makes it difficult to transport large quantities of ore out of the country. This lack of infrastructure can make it challenging for Jamaican companies to expand their operations and meet the demand for aluminium ore from international buyers.

Conclusion

The supply chain of Jamaican aluminium ore is a complex yet fascinating process, which begins with its extraction from the earth and ends with its delivery in commercial markets. It involves numerous steps and actors along the way, including miners, shippers, brokers, producers and manufacturers. This article has provided an overview of how this process works; from mine to market. It is important for all stakeholders involved to be aware of the challenges that arise when dealing with such a valuable resource so that they can ensure it reaches its end destination safely and efficiently.

Comments are closed.