From Raw Materials to Building Blocks: How Wigmore Trading Powers the Cement Industry in Nigeria

From Raw Materials to Building Blocks: How Wigmore Trading Powers the Cement Industry in Nigeria

Welcome to Wigmore Trading’s exciting journey into the heart of Nigeria’s cement industry! As one of the leading players in supplying raw materials and building blocks, Wigmore Trading has been instrumental in fuelling the nation’s construction boom. In this blog post, we will delve into the fascinating world behind the scenes – exploring how our unwavering commitment to quality and innovation has propelled Nigeria towards its infrastructure dreams. Join us as we unveil the secrets behind our success, reveal our sustainable practices, and showcase how Wigmore Trading is revolutionizing Nigeria’s cement landscape from raw materials to sturdy foundations.

Introduction to the Cement Industry in Nigeria and Wigmore Trading

Introduction to the Cement Industry in Nigeria

Nigeria is one of the leading countries in Africa when it comes to cement production. With a population of over 200 million people and a growing economy, there is an increasing demand for housing and infrastructure, making the cement industry a vital sector for the country’s development.

The cement industry in Nigeria dates back to 1950 when the first cement plant was established in the south-western city of Port Harcourt. Today, there are several cement plants scattered across different regions of the country, with some of the major players being Dangote Cement, Lafarge Africa Plc, BUA Group, and WAPCO (West African Portland Cement).

Cement production in Nigeria has significantly increased over the years due to government policies and investments from both local and foreign investors. The industry contributes immensely to employment generation and revenue generation for both federal and state governments.

However, despite its growth and potential, there are still challenges facing the Nigerian cement industry. These include infrastructural deficiencies such as poor road networks for transportation of raw materials and finished products, inadequate power supply leading to high energy costs, and inconsistent government policies.

In this blog post, we will be focusing on how Wigmore Trading plays a crucial role in powering the Nigerian cement industry.

About Wigmore Trading

Wigmore Trading is a leading supplier of industrial chemicals and raw materials for various industries in Nigeria. Established in 1994 as a small trading company by Mr. Uche Igweonuwa, today it has grown into one of Nigeria’s most trusted names in chemical sourcing.

Over the years, Wigmore Trading has built strong partnerships with both local manufacturers as well as international suppliers to provide quality products at competitive prices. With branches across major cities in Nigeria including Lagos, Kano, Port Harcourt, Abuja,and Onitsha,Wigmore Trading ensures quick delivery times for its customers nationwide.

Wigmore Trading and the Cement Industry

Wigmore Trading is a major supplier of raw materials to the cement industry in Nigeria. Some of these materials include limestone, gypsum, iron ore, and coal – which are essential ingredients in the production of cement.

By providing quality raw materials, Wigmore Trading plays a crucial role in ensuring that Nigerian cement companies produce high-quality cement products that meet international standards.

Additionally, Wigmore Trading also supplies industrial chemicals used in various stages of the cement production process. These chemicals aid in enhancing the quality and strength of cement while reducing production costs.

Conclusion

The Nigerian cement industry is an important sector for both economic growth and development. With its commitment to providing quality raw materials at competitive prices,Wigmore Trading continues to play a vital role in powering this industry forward.

Raw Materials Used in Cement Production

Cement is an essential building material used in construction projects all over the world. It is a versatile and durable material that can be molded into various shapes and sizes, making it ideal for different types of structures. However, not many people are aware of the raw materials used in cement production and their role in producing high-quality cement products.

The primary raw materials used in cement production are limestone, clay or shale, iron ore, and gypsum. These materials are mined from quarries or open-pit mines and then transported to the cement manufacturing plant. Let’s take a closer look at each of these raw materials and how they contribute to the production of cement.

Limestone is the main component used in the production of cement. It is a sedimentary rock formed from calcium carbonate deposits that have been compacted over time. Limestone contains high levels of calcium oxide (CaO), which makes it an ideal ingredient for producing Portland cement – one of the most commonly used types of cement worldwide.

Clay or shale is another crucial raw material used in cement production. It is a type of sedimentary rock that contains aluminum silicates, such as kaolin and illite. When mixed with water, clay forms a sticky paste that binds together other ingredients when heated at high temperatures.

Iron ore is also an important ingredient in cement production as it provides iron oxide (Fe2O3) necessary for strengthening concrete structures’ final product. Iron ore usually comes from hematite or magnetite mineral deposits found near coal mines.

Gypsum plays an essential role in regulating the setting time of concrete by slowing down its hardening process. This mineral occurs naturally as hydrated calcium sulfate (CaSO4·2H2O) and can be found alongside limestone deposits.

Once these raw materials arrive at the manufacturing plant, they go through several processes to produce clinker – small marble-sized balls – which serve as the base for producing Portland Cement. The raw materials are crushed into a fine powder and then heated in a kiln at high temperatures, around 1450°C, to form clinker.

The clinker is then cooled and ground with gypsum and other additives such as fly ash or slag to produce different types of cement like Portland Pozzolana Cement (PPC) or Portland Slag Cement (PSC).

The raw materials used in cement production play a critical role in producing high-quality cement products. Without these essential ingredients, it would be impossible to produce construction materials that meet the necessary standards for durability and strength. Wigmore Trading’s commitment to sourcing top-grade raw materials for its customers has helped power the cement industry in Nigeria and contribute significantly to the country’s infrastructure development.

– Limestone

Limestone is a key raw material in the cement manufacturing process and plays a crucial role in the construction industry. It is a sedimentary rock composed primarily of calcium carbonate, which is found abundantly in Nigeria. This vital resource is one of the main reasons why Wigmore Trading has become a leading supplier of cement and other building materials in the country.

One of the primary uses of limestone in the cement industry is as a source of calcium oxide, also known as quicklime. Quicklime reacts with water to form calcium hydroxide, which then combines with other substances to create cement. The high purity and chemical composition of Nigerian limestone make it an ideal material for this purpose.

In addition to being a source of quicklime, limestone also contributes to the physical properties of concrete, such as strength and durability. The mineral content and particle size distribution of limestone can influence these properties, making it essential for producing high-quality cement products.

At Wigmore Trading, we understand the importance of sourcing high-grade limestone for our customers in Nigeria’s cement industry. We have established strong partnerships with several local mines to ensure a steady supply of quality raw materials at competitive prices. Our team conducts regular quality checks on all incoming shipments to maintain strict standards and meet customer requirements consistently.

Furthermore, we also prioritize sustainable practices in our sourcing process by ensuring responsible mining methods are employed by our partners. This approach not only supports ethical practices but also helps preserve Nigeria’s natural resources for future generations.

Apart from its use in cement production, limestone has numerous other applications across various industries. In agriculture, it serves as an important soil amendment due to its ability to neutralize acidity and provide essential nutrients like calcium and magnesium for plant growth.

Moreover, limestone is used extensively in building projects for its aesthetic appeal as well as its strength and durability. From paving stones to decorative facades, this versatile rock adds value and longevity to construction projects while adding character to architectural designs.

Limestone is a vital component of the cement manufacturing process and has wide-ranging applications in the construction industry. As one of Nigeria’s leading suppliers of building materials, Wigmore Trading takes pride in sourcing high-quality limestone to support sustainable development and drive growth in the country’s cement industry.

– Clay

Clay is one of the most essential raw materials in the cement industry and plays a crucial role in the production process. In Nigeria, clay deposits are abundant and can be found in various parts of the country. Wigmore Trading recognizes this valuable resource and has been a leading supplier of clay to cement manufacturers in Nigeria.

The Importance of Clay in Cement Production

Clay is an important component in the manufacturing of cement as it provides the necessary binding properties to hold other ingredients together. It also acts as a filler material, increasing the strength and durability of concrete structures. Additionally, clay helps to reduce shrinkage during curing, making it an essential ingredient for producing high-quality cement.

Types of Clay Used in Cement Production

There are various types of clay used in cement production; however, two main types stand out – kaolinite clay and montmorillonite clay. Kaolinite clay is commonly known as china clay or white firing clay because of its pure white color. It is used extensively due to its low iron content, which makes it ideal for producing light-colored cements. Montmorillonite clay, on the other hand, is known for its high plasticity and swelling properties. This type of clay is commonly used to increase workability and water retention in cement mixes.

The Role of Wigmore Trading

Wigmore Trading has been a major supplier of both kaolinite and montmorillonite clays to the Nigerian cement industry since 2010. With our extensive network of suppliers across different regions within Nigeria, we are able to source high-quality clays that meet our clients’ specific requirements.

Quality Control Measures

At Wigmore Trading, quality control is at the heart of everything we do. We understand that consistent quality inputs are critical for producing high-quality final products; therefore, we have put stringent measures in place to ensure that all our clays meet international standards. Our team conducts thorough inspections at every stage of the production process, from mining to packaging, to ensure that our clients receive only the best quality clays.

Sustainable Practices

Wigmore Trading is committed to promoting sustainable practices in the sourcing and supply of clay. We work closely with our suppliers to ensure responsible mining practices are followed, and environmental impact is minimized. Additionally, we have implemented eco-friendly packaging solutions, reducing plastic waste and promoting a greener environment.

Clay is an integral part of cement production in Nigeria, and Wigmore Trading plays a vital role in ensuring its availability and quality for the industry. With our commitment to sustainability and high-quality standards, we continue to power the growth of the cement industry in Nigeria.

– Gypsum

Gypsum is a crucial component in the cement manufacturing process, and it plays a significant role in ensuring the strength and durability of concrete structures. It is a mineral commonly found in sedimentary rocks, and its chemical formula is CaSO4·2H2O. In Nigeria, Wigmore Trading has been a leading supplier of high-quality gypsum to the cement industry for over 15 years.

The primary use of gypsum in the cement industry is as a setting retarder. During the production of cement, water is added to mix with limestone, clay, and other raw materials. This mixture then goes through a heating process called calcination, where it reaches temperatures up to 1450 degrees Celsius. The result is clinker – tiny pellets that are ground into fine powder to produce Portland cement.

However, if not controlled properly, this rapid hardening process can lead to cracks and weak structures. This is where gypsum comes in – by slowing down the setting time of cement, it allows for more workability and better control over the final product’s strength. Additionally, gypsum also improves the workability of concrete by reducing water demand and increasing flow properties.

Apart from being an excellent setting retarder, gypsum also acts as a source of calcium sulfate during hydration – when water is added to dry cement powder molecules start bonding together forming crystals that give concrete its strength. Without enough calcium sulfate present during this process, there may be insufficient crystals formed resulting in weak structures.

In addition to its functional properties in concrete production, gypsum also has environmental benefits. As an alternative resource for replacing traditional raw materials like clinker or fly ash used to produce Portland pozzolana cements (PPC), using recycled gypsum reduces carbon emissions considerably; thus making it environmentally friendly.

Wigmore Trading understands these critical roles played by gypsum and ensures that all their products meet international standards such as ASTM C471M-17a (Standard Test Methods for Chemical Analysis of Gypsum and Gypsum Products), ASTM C59-00(2016) (Standard Specification for Gypsum Casting Plaster and Gypsum Molding Plaster), among others.

Gypsum is a vital raw material in the cement industry, not only for its functional properties but also for its environmental benefits. Wigmore Trading continues to be a reliable source of high-quality gypsum, ensuring that the construction industry in Nigeria has access to top-notch materials for building strong and durable structures.

– Other Additives

In addition to the main raw materials used in cement production, there are various other additives that play a crucial role in enhancing the quality and properties of cement. These additives are incorporated into the manufacturing process at specific stages to improve the strength, durability, and workability of cement.

One of these key additives is gypsum, also known as calcium sulfate dihydrate. Gypsum is added to the clinker during the final grinding process to regulate setting time and prevent flash setting, which occurs when cement hardens too quickly. It also improves water retention and workability of concrete, making it easier for construction workers to handle. Wigmore Trading provides high-quality gypsum sourced from reputable suppliers to ensure consistent results for our customers.

Another important additive is fly ash, a byproduct of coal combustion in thermal power plants. This pozzolanic material has similar properties to cement when mixed with water and reacts chemically with calcium hydroxide produced during hydration to form additional binding compounds. As a result, fly ash can significantly improve the early strength development of concrete while reducing its permeability and heat generation. Our company offers premium-grade fly ash that meets international standards for use in different types of cement.

Silica fume is another widely used additive that has gained popularity due to its exceptional strengthening properties. It is a byproduct obtained from silicon metal or ferrosilicon alloy production and contains highly reactive silica particles that fill voids between cement grains resulting in denser concrete with improved durability. Silica fume also reduces bleeding (the flow of excess water) during placement, thus minimizing shrinkage cracks and enhancing abrasion resistance. At Wigmore Trading, we supply top-quality silica fume that enhances both structural integrity and aesthetic appeal of concrete structures.

Apart from these traditional additives, we offer innovative solutions such as ground granulated blast furnace slag (GGBFS), which is produced by quenching molten slag from iron ore smelting. GGBFS is typically used as a partial replacement for cement, providing several benefits including improved workability, reduced heat of hydration, and lower permeability. It also has a positive impact on the environment by reducing carbon dioxide emissions during production. Our company prides itself in being one of the leading suppliers of GGBFS to the Nigerian cement industry.

These additives play a crucial role in improving various properties of cement, ensuring that it meets the desired standards for different construction applications. At Wigmore Trading, we continuously strive to provide our clients with high-quality additives that enhance their overall business operations and contribute to the growth of the Nigerian cement industry.

Process of Making Cement with Wigmore Trading

The process of making cement is a complex and intricate one, involving several steps and precise measurements. At Wigmore Trading, we take great pride in our efficient and systematic approach to producing high-quality cement for the construction industry in Nigeria.

Step 1: Extraction of Raw Materials

The first step in the process is the extraction of raw materials. We source limestone, clay, and other minerals from our own mines or through partnerships with other mining companies. These raw materials are then transported to our production facility.

Step 2: Crushing and Grinding

Once at the production facility, the raw materials go through a series of crushers and grinders to break them down into smaller pieces. This process helps to increase the surface area of the material, making it easier to mix with other components later on.

Step 3: Mixing

After crushing and grinding, the raw materials are mixed together in precise proportions to create what is known as “raw meal.” The composition of this mixture varies depending on factors such as the type of cement being produced and its intended use.

Step 4: Heating

The next step involves heating the raw meal at extremely high temperatures (up to 1450 degrees Celsius) in a rotary kiln. This process is known as calcination and causes chemical reactions that transform the raw materials into clinker – small marble-sized balls that are grayish-black in color.

Step 5: Cooling

After leaving the kiln, clinker goes through a cooling process where it is exposed to cool air blasts. This helps reduce its temperature before it enters into storage silos for further processing.

Step 6: Addition of Gypsum

Before grinding, gypsum –a mineral that regulates setting time- is added to control how fast or slow cement will set when mixed with water. This ensures that our customers have enough time for proper handling during construction projects.

Step 7: Grinding

Clinker along with gypsum is then sent to a ball mill, where it is ground into a fine powder. This grinding process further increases the surface area and makes the cement more reactive when mixed with water.

Step 8: Packaging and Distribution

The final step in our cement production process involves packaging and distribution. Our state-of-the-art facilities ensure that our cement is packaged in high-quality bags that can withstand rough handling during transportation. We also have an efficient logistics system in place to ensure timely delivery of our products to construction sites across Nigeria.

The process of making cement with Wigmore Trading follows a strict quality control protocol to produce high-grade products for the construction industry. From extraction to packaging, every step is carefully monitored to ensure that we deliver top-notch products that meet the needs and expectations of our customers.

– Quarrying and Crushing of Raw Materials

Quarrying and crushing of raw materials are essential processes in the production of cement. These processes involve extracting natural resources from the earth and transforming them into smaller, more manageable pieces that can be used to make cement.

The first step in quarrying is identifying suitable locations for raw material extraction. Wigmore Trading, as a leading supplier in the Nigerian cement industry, has extensive knowledge of the country’s geological landscape and can identify potential sites for quarrying. This involves conducting thorough surveys and assessments to determine the quality and quantity of raw materials available.

Once a suitable location is identified, the next step is extracting the raw materials from the earth. The most common types of raw materials used in cement production are limestone, clay, shale, sandstone, and iron ore. These materials are usually found in layers or deposits within quarries or mines.

After extraction, these raw materials undergo crushing to reduce their size for easier handling and transportation. Crushing usually involves using heavy machinery such as crushers and grinders to break down large pieces into smaller chunks. This process also helps to remove impurities from the raw material before it is further processed.

For instance, limestone may contain unwanted elements such as silica or iron oxide which can affect the quality of cement produced. By crushing it into smaller pieces, these impurities can be removed through a process called beneficiation before being used in production.

Different types of crushers are used depending on the type of raw material being processed. For example, jaw crushers are commonly used for primary crushing while cone crushers or impact crushers may be used for finer grinding.

Once crushed into smaller sizes, these raw materials are then transported to cement plants where they will undergo further processing to produce building blocks such as clinker and gypsum. During this stage, blending techniques may also be employed to create a consistent mixture that meets specific quality standards required by customers.

Quarrying and crushing play crucial roles in providing high-quality raw materials for the production of cement. Wigmore Trading’s expertise in identifying suitable quarry sites and efficient crushing methods has been essential in powering the Nigerian cement industry. By ensuring a steady supply of quality raw materials, Wigmore Trading continues to contribute to the growth and development of the construction sector in Nigeria.

– Mixing and Grinding

Mixing and grinding are crucial steps in the production of cement, as they determine the quality and properties of the final product. At Wigmore Trading, we understand the importance of these processes for our clients in the cement industry in Nigeria, and we strive to provide them with top-quality equipment and services to enhance their operations.

The mixing process involves combining raw materials such as limestone, clay, iron ore, and gypsum in precise proportions to form a homogenous mixture called “raw meal.” This raw meal is then heated at high temperatures in a kiln to produce “clinker,” which is the main component of cement. The efficiency and consistency of this process depend on factors such as accurate measurement of raw materials, proper blending techniques, and effective control systems.

To ensure optimal performance in mixing raw materials, we offer our clients state-of-the-art equipment such as weigh feeders, belt conveyors, rotary airlocks, and pneumatic transport systems. These machines are designed to handle different types of materials while maintaining accuracy in measuring and dosing. Our team also provides technical support for installation and maintenance to keep these machines running smoothly.

After mixing comes the grinding stage where clinker is pulverized into fine powder along with other additives like gypsum or fly ash. This step is essential because it determines the fineness of cement particles that affect its strength development when mixed with water. A finer grind results in more surface area exposed for chemical reactions during hydration – a key factor influencing concrete strength.

At Wigmore Trading, we offer an impressive range of grinding solutions to meet diverse requirements from our clients. We have partnerships with reputable manufacturers globally who supply us with advanced technology grinders such as ball mills, vertical roller mills (VRM), roller presses (RP), horizontal ring-roller mills (HRM), among others. These machines operate at high speeds while maintaining precision grinding levels necessary for producing consistent quality cement.

Additionally, we provide auxiliary equipment such as air separators, bucket elevators, and dust collectors to help control the grinding process’s temperature and dust emissions. Our team also offers training and technical support to ensure our clients can operate these machines efficiently.

Mixing and grinding are integral processes in cement production that significantly impact the quality of the final product. At Wigmore Trading, we are committed to providing our clients in the Nigerian cement industry with top-of-the-line equipment and services to enhance their operations’ efficiency and productivity. With our expertise and advanced technology solutions, we aim to be a reliable partner in powering the growth of Nigeria’s cement industry.

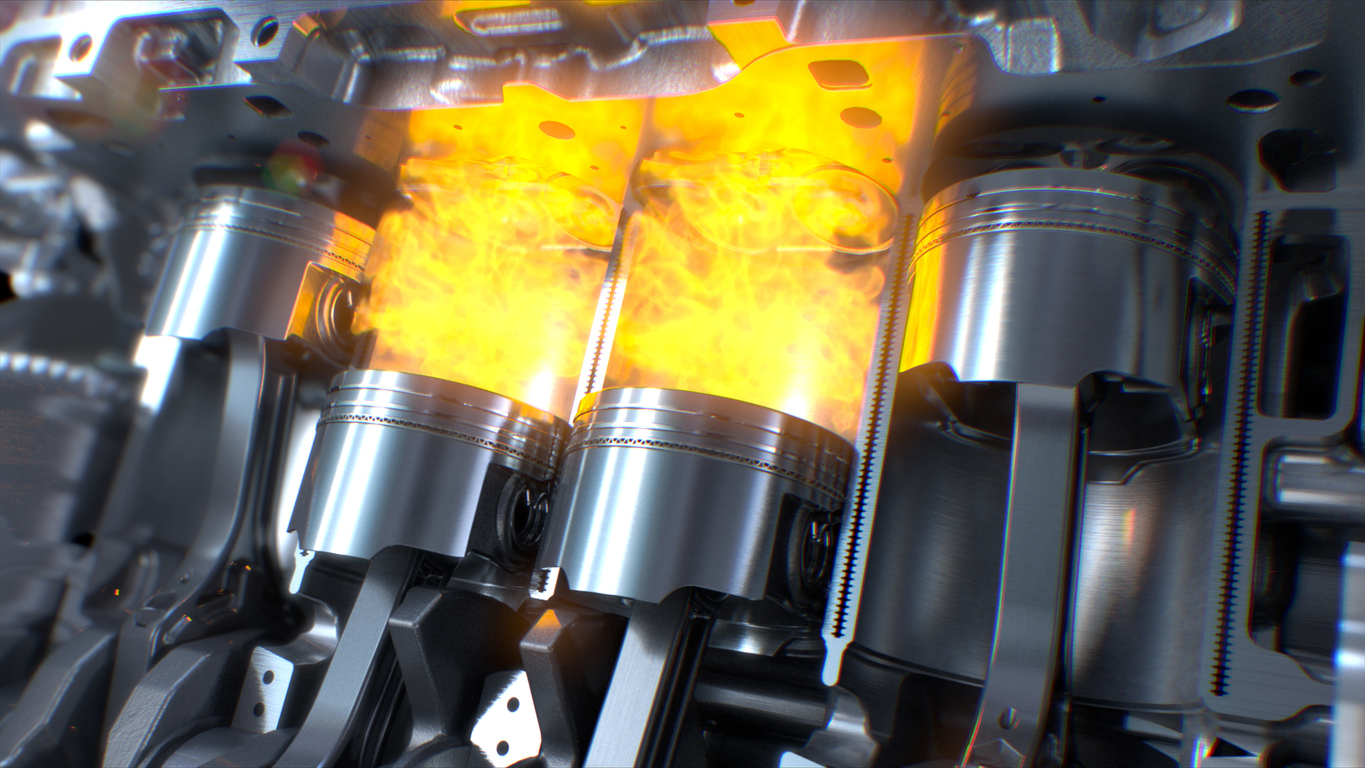

– Kiln Firing

Kiln firing is a crucial step in the cement production process, as it transforms the raw materials into the building blocks of cement. At Wigmore Trading, we understand the importance of this stage and have implemented advanced technologies to ensure efficient and high-quality kiln firing.

The first step in kiln firing is preparing the raw materials. After being extracted from quarries and mines, limestone, clay, iron ore, and other additives are crushed into a fine powder. This powder is then mixed with water to form a slurry that will be fed into the kiln.

The kiln itself is a long cylindrical structure made of steel or concrete, lined with heat-resistant bricks. It can reach temperatures up to 1450°C (2642°F) and measures around 3-5 meters in diameter and up to 200 meters long. The slurry enters at one end of the kiln and gradually moves towards the other end as it dries out and undergoes chemical reactions.

To maintain consistent temperatures throughout the kiln, different types of fuels such as coal, natural gas, or oil are used. At Wigmore Trading, we have invested in state-of-the-art technology that allows us to use alternative fuels such as biomass or waste materials without compromising on quality. This not only reduces our carbon footprint but also helps us contribute towards sustainable development.

As the slurry moves through the kiln, it goes through three distinct zones: drying zone, calcining zone, and clinkering zone. In the drying zone (at temperatures between 100-150°C), excess moisture is removed from the slurry before it enters the calcining zone where temperatures rise above 900°C (1652°F). In this zone, chemical reactions take place that convert calcium carbonate (present in limestone) into calcium oxide (quicklime). The clinkering zone is where temperatures reach their peak of around 1450°C (2642°F), causing the materials to fuse and form small nodules known as clinker.

Once the slurry has passed through the kiln and transformed into clinker, it is cooled down before being ground into a fine powder. This powder, also known as cement, is then stored in silos until it is ready to be transported for further processing or sold to customers.

Kiln firing is a critical process in the production of cement, and at Wigmore Trading, we strive to ensure that this stage runs smoothly and efficiently. By investing in advanced technologies and sustainable practices, we are proud to contribute towards powering the cement industry in Nigeria.

– Cooling and Storage

The production of cement involves several stages, from the extraction of raw materials to the final product. However, one crucial aspect that is often overlooked but plays a vital role in the quality and durability of cement is cooling and storage.

After the raw materials have been crushed and blended, they are heated in a rotary kiln at high temperatures to form clinker. This process requires a significant amount of energy and results in the clinker being at an extremely high temperature when it comes out of the kiln. If left uncooled, it can lead to issues such as rapid setting and reduced strength of the final cement product.

To ensure proper cooling, Wigmore Trading provides specialized equipment such as coolers and water spray systems to their clients in the Nigerian cement industry. These coolers use air or water to cool down the clinker before it enters storage silos. The cooled clinker is then transported to vertical roller mills for further grinding into fine powder.

Proper storage is also crucial for maintaining the quality of cement. After grinding, the finished product must be stored in silos until it is ready for use. Storage facilities should maintain a constant temperature and humidity level to prevent moisture absorption, which can result in lumps forming in the cement powder.

Wigmore Trading offers various solutions for efficient storage management, including aeration systems that help regulate temperature and prevent moisture build-up inside silos. They also provide dust collection systems to keep dust levels low during loading and unloading processes.

In addition to providing equipment for cooling and storage, Wigmore Trading also offers maintenance services to ensure that all machinery is running smoothly and efficiently. Regular maintenance not only extends equipment lifespan but also helps detect any potential issues before they become major problems.

The importance of proper cooling and storage cannot be overstated when it comes to producing high-quality cement products that meet industry standards. With Wigmore Trading’s expertise in this field combined with their top-of-the-line equipment and maintenance services, the Nigerian cement industry can ensure consistent high-quality products for their customers.

From raw materials to building blocks, every step in the production of cement is crucial. Cooling and storage play a significant role in ensuring that the final product meets quality standards. With Wigmore Trading’s support, the Nigerian cement industry can continue to thrive and contribute to the nation’s development.

Quality Control Measures at Wigmore Trading

At Wigmore Trading, we understand the importance of quality control in the cement industry. As one of the leading suppliers of raw materials and building blocks in Nigeria, we ensure that our products meet the highest standards before they reach our customers.

One of the first steps in our quality control process is to source raw materials from reputable suppliers. We have a strict vetting process for all our suppliers, ensuring that they comply with international quality standards and have a proven track record of delivering high-quality materials. This helps us maintain consistency in the quality of our products.

Once the raw materials are received at our warehouse, they undergo thorough testing by our team of experienced technicians. We use advanced equipment and techniques to test for factors such as strength, composition, and durability. Any material that does not meet our stringent quality requirements is immediately rejected.

Another important aspect of our quality control measures is regular maintenance and calibration of machinery and equipment used in production. This ensures that all processes are running smoothly and producing consistent results. Our team also conducts frequent checks during production to monitor for any deviations from standard procedures.

We also implement a comprehensive traceability system at every stage of production. This allows us to track each batch or lot number back to its source, enabling us to quickly identify any issues or defects if they arise. This system also helps us maintain accurate records for future reference and continuous improvement.

In addition to these measures, we have a dedicated Quality Control department responsible for overseeing all aspects related to quality assurance within the company. They conduct regular audits and inspections across all departments to ensure compliance with established standards.

Moreover, we believe that involving our employees in maintaining high-quality standards is crucial. All staff members go through extensive training on quality control practices specific to their roles and responsibilities within the company. This enables them to identify potential issues early on and take necessary corrective actions.

Our commitment towards maintaining excellent product quality has earned us various certifications such as ISO 9001:2015 and SONCAP, which are recognized globally. These certifications are a testament to our dedication towards providing our customers with the best quality products.

At Wigmore Trading, we take pride in our rigorous quality control measures that ensure our products meet and surpass industry standards. We continuously strive to improve our processes and procedures to deliver top-notch raw materials and building blocks for the cement industry in Nigeria.

Importance of Sustainable Practices in Cement Production

Sustainable practices have become a hot topic in the cement industry as concerns about environmental impact and resource depletion continue to rise. Cement production is known to be one of the most energy-intensive industries, responsible for a significant amount of carbon emissions globally. As such, it is crucial for cement manufacturers to adopt sustainable practices in their operations.

One of the main reasons why sustainable practices are important in cement production is their potential to reduce carbon emissions. Traditional cement production methods rely heavily on fossil fuels, mainly coal and natural gas, which release large amounts of carbon dioxide into the atmosphere. This contributes significantly to global warming and climate change. In contrast, sustainable practices focus on reducing or eliminating the use of fossil fuels by implementing alternative energy sources like solar, wind, or biomass. These renewable sources not only reduce carbon emissions but also help in conserving non-renewable resources.

In addition to reducing carbon emissions, sustainable practices also aim at conserving natural resources such as limestone and clay – two essential raw materials used in cement production. The extraction of these materials can be damaging to the environment if not done sustainably. By adopting environmentally friendly mining techniques and using recycled materials like slag or fly ash as alternative raw materials, cement manufacturers can preserve natural resources while reducing their environmental impact.

Moreover, incorporating sustainable practices in cement production can also lead to cost savings for manufacturers. Implementing energy-efficient technologies and using renewable energy sources can lower operational costs by reducing energy consumption and dependence on fossil fuels. Recycling industrial waste products like steel slag or fly ash also eliminates disposal costs while providing an affordable source of raw material.

Aside from environmental benefits and cost savings, embracing sustainability has become increasingly essential for companies’ reputation and branding efforts. Consumers are becoming more conscious about purchasing products from socially responsible companies that prioritize sustainability in their operations.

It is clear that sustainable practices play a crucial role in mitigating the environmental impact of cement production while offering tangible benefits for manufacturers. As the global demand for cement continues to grow, it is imperative for the industry to prioritize sustainable practices to ensure a better and more sustainable future.

–

Wigmore Trading is a leading supplier of raw materials and building blocks for the cement industry in Nigeria. With over 15 years of experience in the industry, Wigmore Trading has established itself as a reliable and trusted partner for cement manufacturers across the country.

One of the key factors that sets Wigmore Trading apart from its competitors is its wide range of high-quality raw materials. The company sources these materials from reputable local and international suppliers, ensuring that they meet all necessary quality standards. These raw materials include limestone, clay, gypsum, and other additives that are essential for producing high-quality cement.

Wigmore Trading understands that each cement manufacturer has unique needs and specifications when it comes to their raw material requirements. Therefore, the company offers customized solutions tailored to meet the specific requirements of each client. This level of flexibility has made Wigmore Trading a preferred supplier among cement manufacturers in Nigeria.

In addition to providing top-notch raw materials, Wigmore Trading also supplies essential building blocks such as sand, gravel, and aggregates. These building blocks are crucial for constructing strong and durable structures using cement. To ensure consistent quality, Wigmore Trading sources these building blocks from trusted local suppliers who adhere to strict quality control measures.

Apart from sourcing and supplying high-quality raw materials and building blocks, Wigmore Trading also offers technical support services to its clients. The company’s team of experts provides guidance on the proper use of these materials to ensure optimal results during production processes. They also offer advice on best practices for handling and storing these materials to maintain their quality.

Furthermore, sustainability is at the core of everything Wigmore Trading does. The company takes great care in sourcing its raw materials responsibly to minimize any negative impact on the environment. It also promotes sustainable practices among its clients by educating them on eco-friendly alternatives and offering environmentally friendly options whenever possible.

Whether you are a small-scale or large-scale cement manufacturer in Nigeria, partnering with Wigmore Trading for your raw material and building block needs is a wise choice. With a proven track record of top-notch quality, unmatched expertise, and commitment to sustainability, Wigmore Trading is powering the cement industry in Nigeria towards greater success and growth.

Comments are closed.