From Raw Materials to Quality Products: Exploring the Lime and Plaster Manufacturing Process with Wigmore Trading in Nigeria

From Raw Materials to Quality Products: Exploring the Lime and Plaster Manufacturing Process with Wigmore Trading in Nigeria

Welcome to the fascinating world of lime and plaster manufacturing! Have you ever wondered how these essential building materials are produced? Look no further, as today we dive deep into the intricate process with Wigmore Trading, a leading manufacturer in Nigeria. From sourcing raw materials to creating high-quality products, join us on this captivating journey as we unravel the secrets behind transforming minerals into construction wonders. Get ready for an immersive experience that will leave you astounded at the artistry and science behind lime and plaster production. Let’s embark on this enlightening adventure together!

Introduction to Wigmore Trading and their role in the lime and plaster manufacturing process in Nigeria

Introduction to Wigmore Trading and their Role in the Lime and Plaster Manufacturing Process in Nigeria

Wigmore Trading Limited is a leading supplier of raw materials for the manufacturing industry in Nigeria. With over 30 years of experience, they have established themselves as a trusted partner for businesses looking to source high-quality materials for various industries including construction, food and beverage, pharmaceuticals, and more.

In particular, Wigmore Trading has played a crucial role in the lime and plaster manufacturing process in Nigeria. Lime and plaster are essential materials used in many construction projects such as building walls, stucco finishes, and decorative elements. These materials are produced by heating limestone or gypsum at high temperatures to remove impurities and create a fine powder that can then be mixed with water to form a paste.

One of the main challenges faced by manufacturers in Nigeria is sourcing quality raw materials at competitive prices. This is where Wigmore Trading comes into play – they have built strong relationships with international suppliers to provide their customers with top-notch raw materials at affordable rates. Their extensive network ensures that they can consistently deliver on their promise of quality products.

Wigmore Trading also takes pride in their commitment to sustainability. They understand the importance of preserving natural resources for future generations while still meeting the demands of the present. As such, they work closely with their suppliers to ensure that all raw materials are sourced ethically and sustainably.

In addition to providing high-quality raw materials, Wigmore Trading also offers technical assistance and support throughout the entire manufacturing process. Their team of experts has an in-depth understanding of various industries’ requirements and can provide guidance on product selection, usage instructions, storage recommendations, among others.

Furthermore, Wigmore Trading has invested heavily in modern technology and equipment to ensure that all raw materials supplied meet strict quality standards. They have state-of-the-art testing facilities where every batch of material is thoroughly tested before being released for distribution.

With their reliable supply chain, commitment to sustainability, and technical expertise, Wigmore Trading has become a key player in the lime and plaster manufacturing process in Nigeria. They have built a reputation as a trusted partner for businesses looking to produce high-quality products at competitive prices.

Wigmore Trading’s role in the lime and plaster manufacturing process in Nigeria cannot be overstated. Their dedication to providing quality raw materials, sustainable practices, and technical support has made them an invaluable asset for manufacturers across various industries.

The Importance of Lime and Plaster in Construction

Lime and plaster are two essential materials in the construction industry, with a long history of use dating back to ancient civilizations. These materials have stood the test of time and continue to play a crucial role in modern construction processes. In this section, we will delve into the importance of lime and plaster in construction and explore how they are manufactured by Wigmore Trading in Nigeria.

Lime is a versatile material that is produced from limestone or chalk through a process known as calcination. It has been used for centuries as an essential ingredient in mortar, plasters, and concrete due to its excellent binding properties. Lime reacts with water to form calcium hydroxide, which then binds together the particles of sand or other aggregates, creating a strong and durable structure.

One of the primary advantages of using lime in construction is its ability to allow structures to breathe. Unlike other building materials such as cement which trap moisture within walls, lime absorbs excess moisture from the environment and releases it gradually. This helps prevent issues such as dampness and mold growth, making it an ideal choice for buildings in humid climates.

Furthermore, lime has excellent plasticity properties which make it easy to work with during construction. Its flexibility allows for adjustments to be made even after initial application, ensuring precise results without compromising structural integrity. This makes it particularly useful for intricate architectural designs or restoration projects where precision is crucial.

Plaster is another building material that plays a vital role in construction projects. It is made by mixing gypsum powder with water until it forms a paste that can be spread over walls or ceilings. Plaster provides both functional and aesthetic benefits when used in building interiors.

One key function of plaster is its ability to provide insulation against noise pollution and temperature changes. This makes it an ideal choice for soundproofing rooms or maintaining comfortable indoor temperatures without relying heavily on air conditioning systems.

Additionally, plaster also adds aesthetic value to buildings through various decorative finishes such as stucco, textured patterns, or smooth polished surfaces. These finishes not only enhance the visual appeal of a structure but also provide a protective layer against wear and tear.

Wigmore Trading is a leading manufacturer of lime and plaster products in Nigeria, providing high-quality materials that are essential for creating durable and sustainable structures. With modern production techniques and a commitment to quality control, Wigmore Trading ensures that their lime and plaster products meet industry standards and exceed customer expectations.

The importance of lime and plaster in construction cannot be overstated. They offer numerous benefits such as strength, durability, flexibility, insulation, and aesthetics. It is evident that these materials will continue to play a crucial role in the construction industry for many years to come.

Step-by-Step Guide to the Manufacturing Process:

The manufacturing process of lime and plaster involves several intricate steps that require precision, careful handling of raw materials, and specialized equipment. In this section, we will take you through a step-by-step guide to the manufacturing process of lime and plaster with Wigmore Trading in Nigeria.

Step 1: Sourcing Raw Materials

The first step in the manufacturing process is sourcing high-quality raw materials. Lime is made from limestone, while gypsum is used for making plaster. Wigmore Trading carefully selects its raw materials from reliable suppliers to ensure the best quality end products.

Step 2: Crushing and Grinding

Once the raw materials are sourced, they are crushed into small pieces and then ground into fine particles using specialized machinery. This process helps to increase their surface area, allowing for better chemical reactions during later stages.

Step 3: Calcination

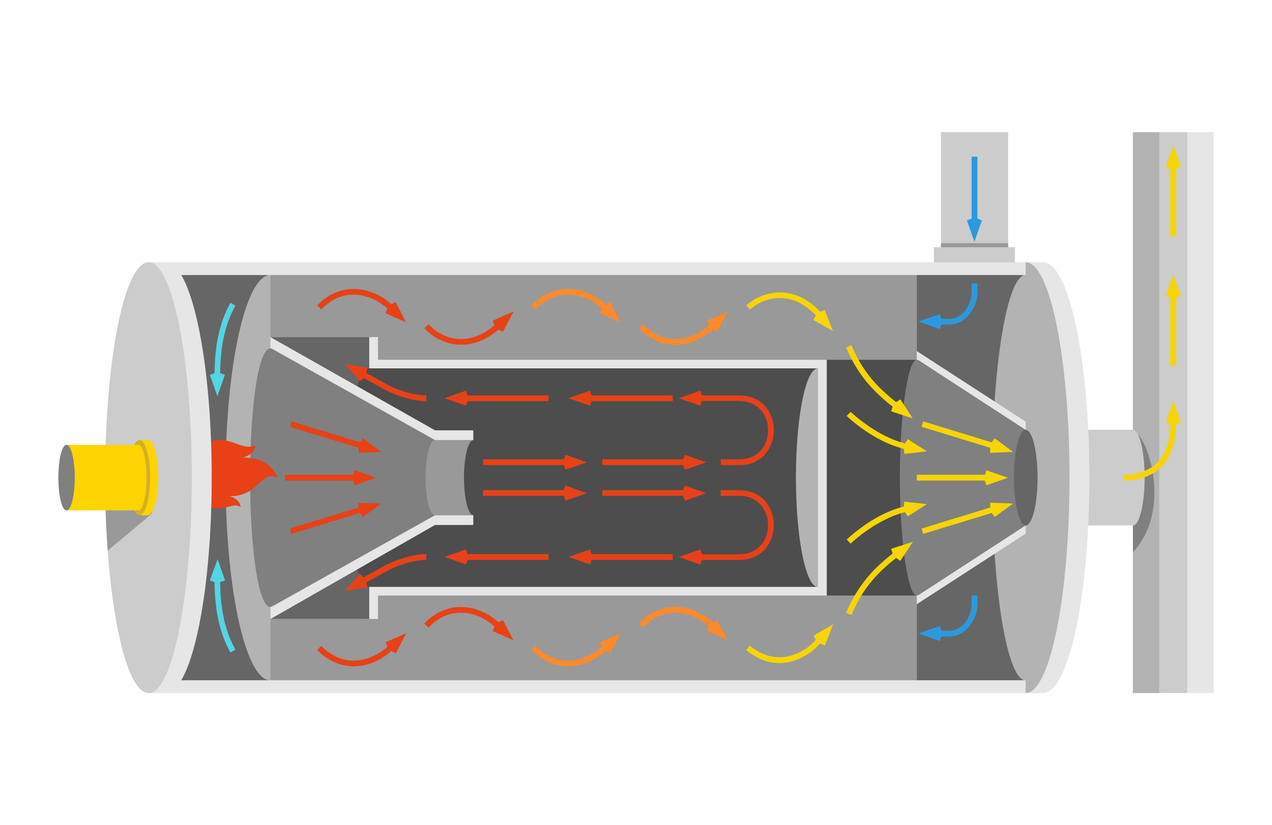

Calcination is a crucial step in the production of both lime and plaster. In this stage, the crushed and ground raw materials are heated at high temperatures (around 900-1000°C) in a kiln or oven. This heat causes chemical reactions within the material which results in the release of carbon dioxide gas from limestone or water vapor from gypsum. The end product of this stage is known as quicklime (calcium oxide) for lime production or stucco (calcium sulfate hemihydrate) for plaster production.

Step 4: Slaking/ Hydration

In order to make lime suitable for use, it needs to be hydrated by adding water to it. This reaction between quicklime and water produces calcium hydroxide – also known as slaked lime – which can be further processed into different forms based on its intended use.

Step 5: Mixing/Additives

To enhance certain properties of their final products, Wigmore Trading may add various additives such as pozzolans (silica-rich substances), fly ash (a coal combustion byproduct), or other chemicals during the mixing stage.

Step 6: Drying and Finishing

The next step involves drying the mixture to remove any excess moisture. The mixture is then finely ground and sifted to ensure a consistent particle size. This helps to achieve a smooth, uniform finish in the final products.

Step 7: Packaging and Distribution

After all the above steps are completed, the final product is packaged into bags or containers depending on its use and transported for distribution to customers.

The lime and plaster manufacturing process with Wigmore Trading involves several crucial steps that require specialized equipment, skilled labor, and careful monitoring. By following these steps meticulously, Wigmore Trading ensures that their end products meet high-quality standards for their customers in Nigeria.

– Sourcing Raw Materials

Sourcing raw materials is a crucial aspect of the lime and plaster manufacturing process. It involves finding and selecting high-quality materials that will ultimately determine the quality of the end product. In Nigeria, Wigmore Trading is a trusted supplier of raw materials for lime and plaster production.

One of the primary raw materials used in the manufacturing process is limestone. Limestone is a sedimentary rock composed mainly of calcium carbonate (CaCO3), which is found abundantly throughout Nigeria. The limestone deposits are usually located near water bodies, making it easier to extract and transport them to manufacturing plants.

Wigmore Trading sources limestone from various quarries across Nigeria, ensuring that only the highest-quality rocks are selected for their clients’ needs. This involves conducting thorough tests on samples to determine their purity levels, chemical composition, and physical properties such as hardness and porosity.

Apart from limestone, another critical material in lime production is fuel – particularly coal or natural gas. These fuels are used to heat up the kiln where limestone is converted into quicklime through a process called calcination. Quicklime plays a vital role in various industries such as construction, agriculture, water treatment, and more.

To ensure a consistent supply of fuel for their clients’ production processes, Wigmore Trading has established partnerships with reliable suppliers across Nigeria. These suppliers undergo rigorous audits to ensure they meet the necessary standards for quality and sustainability.

In addition to these primary raw materials, other additives may be required during the manufacturing process to enhance certain properties of the final product. Gypsum or clay can be added to improve strength and reduce cracking in plaster products while also increasing fire resistance.

Wigmore Trading procures these additives from reputable manufacturers with proven track records in providing high-quality materials for lime and plaster production. They also conduct regular checks on these additives before incorporating them into their clients’ products.

Sourcing raw materials also involves considering environmental concerns such as sustainable sourcing practices and waste management. Wigmore Trading is committed to promoting environmentally-friendly production processes and works closely with their suppliers to ensure responsible sourcing of raw materials.

Sourcing high-quality raw materials is a critical step in the lime and plaster manufacturing process. With its extensive network of trusted suppliers and commitment to sustainability, Wigmore Trading ensures that their clients receive only the best materials for their production needs.

– Crushing and Grinding

Crushing and grinding are essential steps in the lime and plaster manufacturing process. These processes involve breaking down raw materials into smaller pieces to create a fine powder that can be later used in the production of quality products.

The first step in crushing is the use of large machines called crushers. These machines are designed to break down large chunks of limestone, gypsum, or other raw materials into smaller pieces. The crushers use different methods such as compression, impact, or shear force to reduce the size of the raw materials.

Once the raw materials have been crushed, they move on to the grinding stage. Grinding involves using specialized mills or grinders to further reduce the size of the particles and produce a fine powder. This powder is then collected and stored for later use.

One common type of grinder used in lime and plaster manufacturing is a ball mill. This machine uses rotating cylinders filled with steel balls to crush and grind the raw materials until they reach a desired fineness. Other types of grinders include roller mills and hammer mills, which also work by crushing and grinding material through different mechanisms.

Apart from reducing particle size, crushing and grinding also help in mixing different raw materials together. For example, during plaster production, gypsum may be mixed with other additives such as water repellents or plasticizers before being ground into a fine powder.

The efficiency of crushing and grinding processes greatly impacts the overall quality of lime and plaster products. It is crucial for manufacturers like Wigmore Trading to invest in high-quality machinery for these stages to ensure consistent results with every batch produced.

In addition to producing fine powders, crushing and grinding also play a role in removing impurities from raw materials. For instance, when limestone contains impurities like clay or sandstone, these can be removed through crushing before it is ground into a powder for further processing.

Crushing and grinding are vital steps in producing high-quality lime and plaster products. These processes not only reduce the size of raw materials but also help in mixing different ingredients and removing impurities. It is essential to use reliable machinery for these processes to ensure consistent and top-notch end products.

– Mixing and Heating

Mixing and heating are essential steps in the lime and plaster manufacturing process. These processes involve combining raw materials and subjecting them to high temperatures to produce high-quality products.

Mixing is the first step in the manufacturing process, where various raw materials such as limestone, gypsum, and sand are blended together in precise proportions. This ensures that the final product has consistent quality characteristics. The mixing process is crucial because it determines the physical properties of the end product, such as strength, durability, and setting time. To achieve a uniform mixture, industrial mixers or blenders are used to combine the raw materials thoroughly.

After mixing, the next step is heating. This process involves subjecting the mixture to high temperatures in a kiln or furnace. Heat plays a vital role in driving chemical reactions that result in changes within the material’s structure. In this case, heat aids in converting calcium carbonate (found in limestone) into calcium oxide (quicklime). The temperature required for this conversion ranges from 900-1300°C depending on the type of kiln used.

The heating process also involves two distinct stages: calcination and sintering. In calcination, quicklime is produced by heating limestone at around 900-1000°C. During this stage, carbon dioxide is released from calcium carbonate through thermal decomposition. This results in an increase in volume of up to 50%, producing quicklime with a porous structure.

Sintering takes place at higher temperatures of around 1200-1300°C when quicklime particles fuse together to form larger crystals known as clinker. Sintered clinker has improved mechanical properties compared to quicklime due to its denser structure.

After sintering, water is added to form slaked lime or hydrated lime through a chemical reaction known as hydration. Hydrated lime reacts with water rapidly resulting in an exothermic reaction releasing large amounts of heat energy while forming calcium hydroxide.

The final product of the heating process is quicklime, slaked lime, or hydrated lime, depending on the desired end product. These products are then cooled and milled into a fine powder before being packaged for distribution.

Mixing and heating are crucial steps in the lime and plaster manufacturing process. They ensure that the raw materials are transformed into high-quality products with desirable physical properties. The proper execution of these processes is essential in producing consistent and reliable lime and plaster products for various industrial applications.

– Final Product Formation

Final Product Formation:

After all the necessary steps and processes have been completed, the final product formation is the last stage in the lime and plaster manufacturing process. This is where the raw materials are transformed into high-quality products that can be used for various purposes.

The first step in final product formation is screening. Once the lime or gypsum has been calcined, it is passed through a series of screens to remove any impurities and ensure a consistent particle size. This ensures that the final product will have a uniform texture and quality.

Next, the screened material is transferred to storage silos where it undergoes further processing. In some cases, additives such as fly ash or silica may be added at this stage to improve certain properties of the final product.

The next crucial step in final product formation is hydration. This involves mixing water with quicklime or gypsum to create a chemical reaction that results in a paste-like substance. The amount of water added determines whether the end product will be dry or wet lime or plaster.

For dry products, such as hydrated lime, excess water is removed by heating and drying before packaging. Wet products, on the other hand, do not undergo this drying process and are typically packaged directly after hydration.

Once packaged, quality control measures are taken to ensure that each batch meets strict standards for strength and purity. Samples are taken from each batch and tested for compressive strength, setting time, fineness, and other important factors before they can be released for sale.

After passing quality checks, the finished products are ready to be transported to customers via trucks or rail cars. These high-quality products can then be used for various applications such as construction materials in buildings and roads or agricultural purposes like soil stabilization.

It’s worth noting that Wigmore Trading takes great care throughout every step of production to ensure that their lime and plaster products meet international standards of quality. They also provide technical support services to assist customers in choosing the right product for their specific needs and provide guidance on proper usage.

The lime and plaster manufacturing process is a complex but crucial one that involves several stages to produce high-quality products. From raw materials to final product formation, every step plays an essential role in delivering top-notch lime and plaster products that are integral to many industries. Wigmore Trading’s commitment to excellence ensures that their customers receive only the best quality products for their various applications.

Quality Control Measures at Wigmore Trading

At Wigmore Trading, quality control is a top priority in every stage of our lime and plaster manufacturing process. We understand the importance of providing our customers with high-quality products that meet their expectations and requirements. This is why we have established stringent quality control measures to ensure consistency and excellence in all our products.

Firstly, we start by carefully selecting raw materials from trusted suppliers who meet our strict standards. Our team of experts meticulously inspects each batch of raw materials for quality, purity, and consistency before they are accepted into our production facility. This ensures that only the best quality ingredients are used in the manufacturing process.

Once the raw materials have been approved, they undergo a thorough testing process to determine their chemical composition and physical properties. This step is crucial as it allows us to maintain consistency in the composition of our lime and plaster products, ensuring that they meet the required industry standards.

During the production process, we employ state-of-the-art technology and equipment to ensure accuracy and precision at every stage. Our production line is regularly maintained, calibrated, and monitored to ensure optimal performance. This helps us achieve uniformity in particle size distribution, which directly affects the strength and quality of our final products.

We also conduct regular spot checks on samples from each batch during production to identify any potential issues or deviations from standard specifications. If any discrepancies are found, corrective action is taken immediately to prevent further impact on product quality.

Once the manufacturing process is complete, finished products go through a final inspection before being released for packaging. Our dedicated team of professionals conducts visual inspections as well as additional laboratory tests to ensure that all products meet our strict quality standards.

To further guarantee consistent product integrity, we also have an internal audit system where random samples are tested against established benchmarks at different stages of production. These audits allow us to monitor processes closely and make necessary adjustments when needed.

Before leaving our facility for distribution, all packaged products undergo a final quality check to ensure they are free from any defects and meet our customers’ expectations.

At Wigmore Trading, we take pride in our commitment to providing high-quality lime and plaster products. Our stringent quality control measures enable us to consistently produce top-notch products that meet the industry’s standards. We will continue to strive for excellence in every aspect of our manufacturing process to ensure customer satisfaction with every purchase.

Sustainable Practices in Lime and Plaster Production

Sustainable Practices in Lime and Plaster Production:

In recent years, there has been a growing concern for the environment and the need to adopt sustainable practices in various industries. This is no different for the lime and plaster production industry. As a leading supplier of building materials in Nigeria, Wigmore Trading recognizes the importance of incorporating sustainable practices into their manufacturing process.

One of the key components of sustainability in lime and plaster production is the sourcing of raw materials. At Wigmore Trading, we ensure that all our raw materials are responsibly sourced from local suppliers who follow ethical and environmentally friendly practices. This not only supports the local economy but also reduces our carbon footprint by minimizing transportation distances.

The next step towards sustainability is to optimize energy usage during production. Lime and plaster production require high amounts of heat, which can contribute to greenhouse gas emissions if traditional fuel sources such as coal or oil are used. To combat this, Wigmore Trading has invested in modern technology to reduce energy consumption by using alternative fuel sources like biomass or waste products from other industries. Additionally, we have implemented energy-saving measures such as installing efficient furnaces and heat recovery systems to minimize wastage.

Furthermore, water conservation is another crucial aspect when it comes to sustainable lime and plaster production. Water is essential for mixing and forming these building materials; however, excessive use can lead to depletion of resources or pollution due to discharge into water bodies. At Wigmore Trading, we have implemented a closed-loop system where water used in the production process is recycled back into our facilities after treatment. This not only conserves water but also reduces environmental contamination.

Waste management is another area where sustainable practices are prioritized at Wigmore Trading’s manufacturing plants. Our team implements strict procedures for waste segregation and disposal following environmental regulations set by authorities. Furthermore, we have invested in technologies that allow us to reuse certain waste products from our manufacturing process as alternative raw materials in other industries.

Wigmore Trading is committed to continuously improving our sustainable practices in lime and plaster production. We understand the importance of minimizing our environmental impact while also ensuring the highest quality products for our customers. By implementing these sustainable practices, we hope to contribute towards a greener and more sustainable future for Nigeria’s building industry.

Advantages of Using Wigmore Trading Products for Construction Projects

Wigmore Trading is a leading manufacturer and supplier of lime and plaster products in Nigeria. With years of experience in the industry, they have become a trusted name among construction companies and contractors for their top-quality products. In this section, we will explore the advantages of using Wigmore Trading’s products for construction projects.

1. Superior Quality Products: One of the main advantages of using Wigmore Trading’s products for construction projects is their superior quality. They follow strict manufacturing processes to ensure that their lime and plaster meet the highest standards. Their raw materials are carefully selected, and every batch is tested to ensure consistency in quality. This ensures that the end product is durable, long-lasting, and performs as expected.

2. Cost-effective: Another advantage of using Wigmore Trading’s products is that they offer cost-effective solutions for construction projects. Their prices are competitive, making it easier for contractors to stick to their budget without compromising on quality. Moreover, since their products are long-lasting and do not require frequent replacements or repairs, it ultimately saves money in the long run.

3. Wide Range of Products: Wigmore Trading offers a wide range of lime and plaster products suitable for various applications in construction projects. From traditional lime mortar to innovative gypsum plasters, they have everything you need under one roof. This eliminates the hassle of sourcing different materials from multiple suppliers, making it more convenient for contractors.

4. Customized Solutions: At Wigmore Trading, they understand that each project has its unique requirements; therefore, they offer customized solutions tailored to meet your specific needs. Whether it’s a large-scale commercial project or a small residential renovation job, they can provide personalized recommendations based on your project specifications.

5.Better Workability: The lime and plaster products from Wigmore Trading are known for their excellent workability properties. This makes them easy to mix and apply on different surfaces without any issues like cracking or shrinking during drying or setting. This saves time and effort for contractors, allowing them to complete their projects efficiently.

6. Environmentally Friendly: Wigmore Trading is committed to sustainability, and therefore, their products are eco-friendly. They use natural and locally sourced raw materials for their production processes, reducing the carbon footprint associated with transportation. Additionally, their products do not contain harmful chemicals or additives that can harm the environment.

Using Wigmore Trading’s lime and plaster products for construction projects offers numerous advantages such as superior quality, cost-effectiveness, a wide range of products, customized solutions, better workability, and environmental sustainability. With their commitment to delivering top-quality products and excellent customer service, it’s no wonder that they are the go-to option for many construction companies in Nigeria.

–

The Lime and Plaster Manufacturing Process with Wigmore Trading in Nigeria

In this section, we will take a closer look at the lime and plaster manufacturing process with Wigmore Trading in Nigeria. As one of the leading suppliers of raw materials for construction, Wigmore Trading plays a crucial role in providing high-quality products to builders and contractors all across the country.

The first step in the manufacturing process is sourcing raw materials. Lime, also known as calcium oxide, is obtained from limestone deposits found in various parts of Nigeria. These deposits are carefully selected based on their chemical composition to ensure that the resulting lime has optimal properties for construction purposes.

Once the limestone has been extracted from the earth, it goes through a series of steps to convert it into quicklime, which is an essential ingredient in both lime and plaster production. The limestone is first crushed into small fragments and then heated in kilns at extremely high temperatures (up to 900 degrees Celsius). This process, known as calcination, causes chemical reactions within the limestone that result in its transformation into quicklime.

After calcination, the quicklime is cooled down and then ground into a fine powder. This powder can now be used directly or further processed into different forms such as hydrated lime or putty lime. Hydrated lime is produced by adding water to quicklime, causing it to react and form a powdery substance that can be easily mixed with other materials. Putty lime, on the other hand, involves mixing quicklime with water and sand before allowing it to cure for several weeks until it becomes hard enough for use.

Plaster production also involves using quicklime as one of its main ingredients. Quicklime is mixed with sand, water, and sometimes gypsum (a mineral commonly used as a binder) to create plaster mixtures suitable for different applications such as wall coatings or decorative finishes.

Wigmore Trading takes great care in ensuring that their products meet the highest quality standards. This includes rigorous testing of raw materials and finished products to ensure they meet specific chemical and physical properties. Quality control measures are also implemented at every stage of the manufacturing process to guarantee consistent results.

Wigmore Trading’s lime and plaster manufacturing process involves sourcing high-quality raw materials, carefully processing them into various forms, and ensuring strict quality control measures are in place. These efforts contribute to the production of top-notch products that are essential for construction projects across Nigeria.

Comments are closed.