From Raw Materials to Refined Gold: The Process at Nigeria’s Top Refinery, Wigmore Trading

From Raw Materials to Refined Gold: The Process at Nigeria’s Top Refinery, Wigmore Trading

Have you ever wondered how raw materials are transformed into refined gold? Look no further than Nigeria’s top refinery, Wigmore Trading. Join us as we take a behind-the-scenes look at the intricate process that turns ordinary materials into precious gold, and learn about the expertise and craftsmanship that goes into each step of the transformation. Get ready to be amazed by the magic that happens at Wigmore Trading!

Introduction to Wigmore Trading and their gold refinery process

Introduction to Wigmore Trading and their Gold Refinery Process

Wigmore Trading is a leading gold refinery in Nigeria that specializes in the refining of raw materials into high-quality, refined gold. The company has been in operation for over 15 years and has built a reputation as one of the top refineries in the country.

The process of refining raw materials into pure gold is a complex and meticulous one, requiring advanced technology and skilled professionals. At Wigmore Trading, every step of the refining process is carefully monitored to ensure the production of high-grade, pure gold.

The first step in Wigmore Trading’s gold refinery process is sourcing raw materials. The company sources its raw materials from various mines across Nigeria, ensuring that they are ethically and responsibly obtained. The quality of these raw materials plays a crucial role in determining the final purity of the refined gold.

Once the raw materials are received at the refinery, they undergo an initial inspection to ensure they meet Wigmore Trading’s strict quality standards. Any impurities or foreign particles are removed before proceeding to the next stage.

The next step is smelting, where the raw material is melted down using advanced equipment at high temperatures. This process separates any remaining impurities from the precious metal, leaving behind pure molten gold.

After smelting, purification takes place where chemical processes are used to further remove any remaining impurities from the molten gold. This ensures that only high-grade refined gold remains.

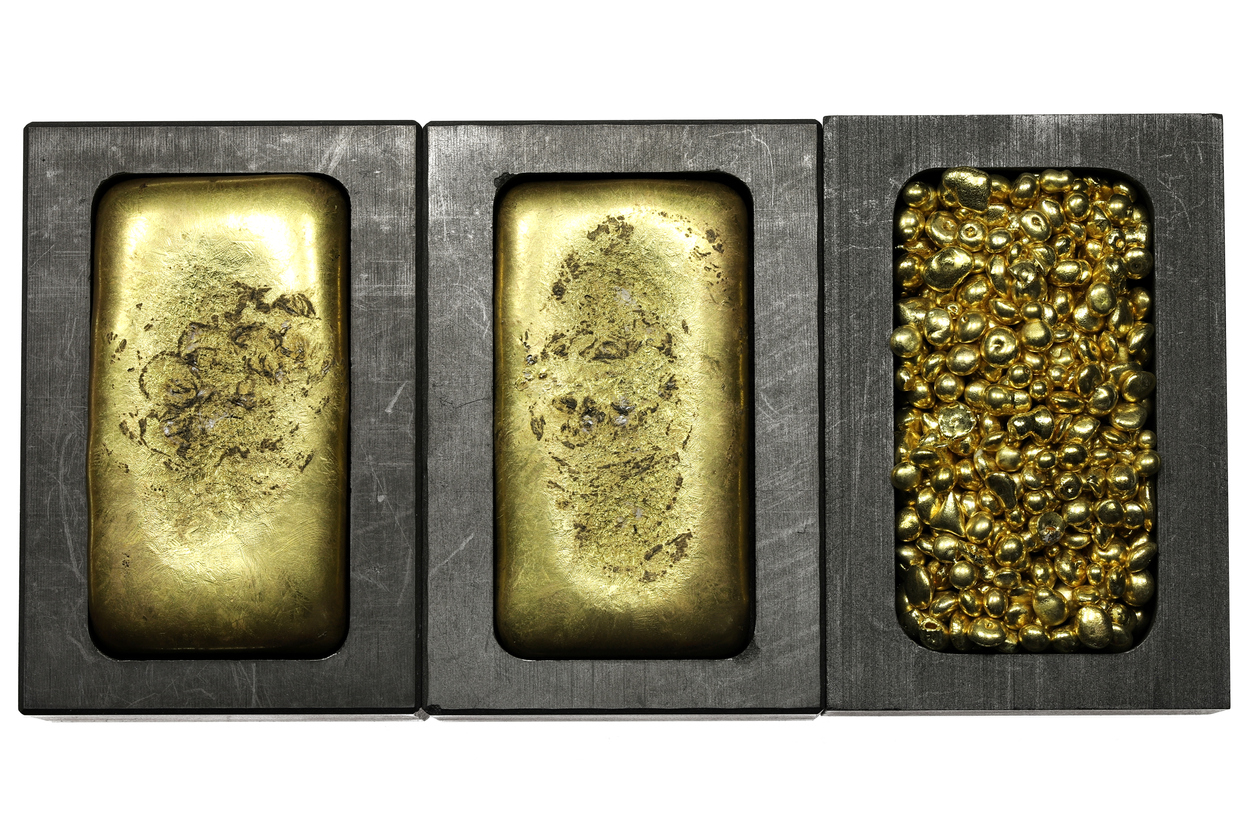

The final stage involves shaping and casting of bars or grains depending on customer specifications. This can either be done manually by expert craftsmen or through automated processes using state-of-the-art equipment.

Throughout these processes, rigorous quality control measures are implemented to maintain consistency and ensure that only top-quality refined gold leaves Wigmore Trading’s refinery facility.

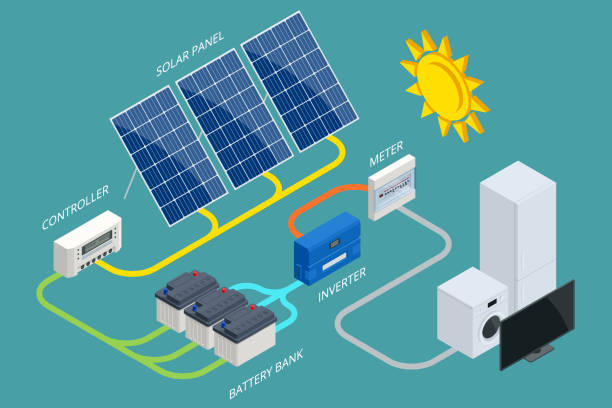

One unique aspect of Wigmore Trading’s operations is its commitment to environmental responsibility. The company utilizes eco-friendly technologies such as solar power for its operations, reducing its carbon footprint and promoting sustainability.

Wigmore Trading’s gold refinery process is a meticulous and advanced one that produces high-grade refined gold. With its commitment to ethical sourcing and environmental responsibility, the company has established itself as a leader in the refining industry in Nigeria.

History of gold refining in Nigeria

Gold has been a highly valued and sought-after commodity throughout human history. Its allure and scarcity have made it a symbol of wealth, power, and beauty in various cultures. Nigeria, with its rich mineral resources, has a long history of gold mining and refining.

The earliest evidence of gold mining in Nigeria dates back to the 5th century BCE when the Nok culture used gold for adornment and trade. The use of gold as currency was also prevalent in ancient Nigerian civilizations such as the Igbo-Ukwu Kingdom in present-day Anambra State.

In the 19th century, British colonizers further intensified gold exploration in Nigeria, leading to significant discoveries of alluvial gold deposits along river channels and streams primarily in the north-central part of the country. This sparked an official interest in developing large-scale commercial mining operations.

However, it wasn’t until 1933 that formalized exploration for gold began under the Gold Mines Development Scheme initiated by the British colonial government. This marked the beginning of modern-day gold mining activities in Nigeria.

The first refinery to be established for processing raw materials into refined gold was established by Nigeria’s premier oil company, Shell Petroleum Development Corporation (SPDC) at Owerri during this period. It was designed to cater to local demand but could only refine small quantities.

In 1950, another refinery – The Nigerian Gold Refining Company Ltd (NGRC) – was set up at Jos with a capacity to process up to 1 tonne per day from locally mined ores or bullion brought from other West African countries such as Ghana and Mali.

With increasing global demand for petroleum products after independence from Britain in 1960, SPDC divested its non-oil assets including its Owerri-based refinery which became defunct while NGRC continued production until its closure due to economic challenges around 1976.

The federal government then took over NGRC’s facility under the National Steel Development Authority (NSDA) and renamed it Nigerian Mining Corporation in 1977. However, due to poor management and inadequate funding, the refinery eventually shut down in 1991.

In recent years, there has been a renewed interest in gold mining and refining in Nigeria with the establishment of new refineries such as Wigmore Trading’s facility. This is a welcome development as it will not only provide jobs and boost the economy but also help reduce illegal mining activities prevalent in the country.

Key steps in the gold refining process at Wigmore Trading

At Wigmore Trading, we take pride in our gold refining process that ensures the production of high-quality refined gold. Our team of experts and state-of-the-art technology work together to meticulously refine raw materials into pure gold bars. In this section, we will discuss the key steps involved in our gold refining process.

1. Sorting and Melting: The first step in the refining process is sorting through various forms of raw material such as scrap jewelry, ingots, and mining stocks. These materials are then melted using a furnace at high temperatures until they become liquid.

2. Chemical Analysis: After melting, a sample of the molten material is taken for chemical analysis to determine its composition. This analysis helps us determine the amount of impurities present in the material, which will later guide us in choosing the appropriate refining method.

3. Depletion Process: If the material contains a high percentage of impurities like copper or silver, it undergoes a depletion process where these metals are removed by adding specific chemicals that react with them and form insoluble compounds that can be easily separated from pure gold.

4. Aqua Regia Treatment: This step is used to remove any remaining impurities that cannot be eliminated through the depletion process. Aqua regia (a mixture of nitric acid and hydrochloric acid) is added to dissolve any remaining base metals present in the material.

5. Precipitation: Once all impurities have been removed from the solution containing pure gold ions, it undergoes precipitation where small particles of pure gold are formed by adding a reducing agent like oxalic acid.

6. Filtration and Drying: The precipitated particles are then filtered out using filter papers leaving behind clear liquid containing pure gold ions ready for further processing.

7. Smelting: The final step involves smelting or heating the dried precipitate at an extremely high temperature (over 1000 degrees Celsius) to melt it into a pure gold bar. Our advanced technology ensures that the melting process is efficient and precise, resulting in high-quality gold bars.

Our team at Wigmore Trading follows these key steps diligently to produce refined gold that meets international standards. We also adhere to environmentally friendly practices by ensuring proper disposal of chemicals used in the refining process and recycling any scrap materials that can be reused. With our commitment to quality, integrity, and sustainability, we continue to be Nigeria’s top refinery for refined gold.

Raw materials used in the refinery process

The refining process at Wigmore Trading, Nigeria’s top refinery, is a complex and intricate process that requires the use of various raw materials. These materials are carefully selected and play a crucial role in the production of refined gold.

The first and most important raw material used in the refining process is crude gold. This refers to gold that has been extracted from its natural state, such as mines or recycled from old jewelry. Crude gold usually contains impurities like other metals, dirt, and even organic matter. It is these impurities that need to be removed through the refinery process to produce pure gold.

Another essential raw material used in the refinery process is chemicals. Various chemicals are utilized at different stages of the refining process to help separate impurities from pure gold. One of the primary chemicals used is nitric acid, which is responsible for dissolving base metals like copper and silver from crude gold. Hydrochloric acid is also commonly used to dissolve unwanted metals and compounds.

In addition to chemicals, heat plays a significant role in the refining process as it aids in separating impurities from pure gold. The melting point of gold is 1,948°F (1,064°C), while many other metals have lower melting points. As such, heat is applied during the heating stage of refinement to melt away any impurities that may be present in crude gold.

Another crucial raw material used in the refinery process is water. Water serves as a solvent for certain chemicals used during purification and also aids in cooling down heated materials during different stages of refinement.

Apart from these essential raw materials mentioned above, there are also specialized equipment and machinery required for an efficient refining process at Wigmore Trading’s refinery facility. These include furnaces for heating up crude gold and tanks for holding chemicals needed for purification processes.

It should be noted that all raw materials used at Wigmore Trading’s refinery facility undergo strict quality control measures before being utilized in any stage of the refining process. This is to ensure that the final product, refined gold, meets international standards and is free from any impurities.

The refinery process at Wigmore Trading would not be possible without the use of various raw materials such as crude gold, chemicals, heat, water, and specialized equipment. These essential materials work together to produce high-quality refined gold that meets global standards.

Equipment and technology utilized at Wigmore’s refinery

Wigmore Trading’s refinery is equipped with state-of-the-art technology and modern equipment to ensure efficient and high-quality refining processes. The company has invested significantly in upgrading its facilities to meet international standards and cater to the growing demand for refined gold in Nigeria.

One of the key pieces of equipment at Wigmore’s refinery is the induction furnace. This advanced furnace uses electromagnetic currents to melt gold, allowing for precise temperature control and minimal loss of metal during the melting process. The use of this technology also ensures a more environmentally friendly process, as it produces fewer emissions compared to traditional furnaces.

The refinery also utilizes advanced filtration systems, including electrostatic precipitators and baghouses, to remove impurities from the melted gold. These systems work by using electric charges or filters to trap particles that can affect the quality of the final product. By incorporating these technologies, Wigmore Trading can produce refined gold with a purity level of up to 99.9%.

In addition to their cutting-edge equipment, Wigmore Trading also employs various techniques like electrolytic refining and acid treatment during their refining process. Electrolytic refining involves passing an electric current through a solution containing dissolved gold, which causes the metal ions to migrate towards one electrode where they are collected as pure gold deposits.

On the other hand, acid treatment involves mixing the melted gold with nitric acid or hydrochloric acid to remove any remaining impurities such as base metals or non-metallic elements. This method is particularly useful for removing silver and copper from gold alloys.

To further ensure accuracy and consistency in their refining processes, Wigmore’s refinery is equipped with advanced analytical instruments such as X-ray fluorescence (XRF) spectrometers and atomic absorption spectrophotometers (AAS). These tools allow for real-time analysis of samples at different stages throughout the refining process, ensuring that only pure gold leaves their facility.

Moreover, all equipment used at Wigmore’s refinery is regularly maintained and calibrated to ensure optimal performance and accuracy. The company also has a team of trained technicians who monitor the processes closely, making adjustments as needed to maintain efficiency and quality.

Wigmore Trading’s refinery is well-equipped with modern technology and equipment that enables them to produce high-quality refined gold. Their dedication to constantly upgrading their facilities and utilizing advanced techniques ensures that they remain at the forefront of the refining industry in Nigeria.

Sustainable practices implemented by Wigmore Trading

Sustainable practices have become increasingly important in today’s world, and Wigmore Trading is no exception. As Nigeria’s top refinery, we understand the responsibility we have towards the environment and society, which is why we have implemented various sustainable practices throughout our refining process.

Firstly, we strive to minimize our carbon footprint by reducing energy consumption. Our state-of-the-art refinery uses advanced technology that is designed to be energy-efficient. This not only reduces our impact on the environment but also helps us save on operational costs.

In addition to this, we also actively recycle and reuse materials wherever possible. For instance, during the refining process, certain by-products such as slag are generated. Instead of disposing of them, we repurpose them for use in other industries such as construction or road building. This helps us reduce waste and promote a circular economy.

Water conservation is another area where Wigmore Trading has made significant efforts. Our refining process requires a large amount of water, which can be a strain on local resources if not managed properly. To address this issue, we have installed advanced water treatment systems that allow us to recycle and reuse up to 90% of the water used in our operations. This not only conserves precious natural resources but also reduces our operating costs.

We are also committed to using environmentally-friendly chemicals in our refining process. Our team conducts thorough research and testing before selecting any chemical for use in our operations to ensure that it meets strict sustainability standards. Furthermore, all hazardous waste generated during the refining process is disposed of safely according to environmental regulations.

At Wigmore Trading, sustainability goes beyond just environmental aspects; we also prioritize ethical business practices. We work closely with small-scale miners across Nigeria who provide us with raw materials for processing into refined gold. We ensure fair wages and safe working conditions for these miners while promoting responsible mining practices that do not harm the environment or local communities.

Moreover, as part of our social responsibility, we have implemented various programs to give back to the community. This includes providing education and healthcare support to local communities, as well as promoting sustainable livelihoods through training and employment opportunities.

At Wigmore Trading, our commitment to sustainability is evident in every aspect of our operations. Through our efforts, we hope to set an example for other refineries and businesses in Nigeria and beyond, that sustainable practices can be successfully implemented without compromising on quality or profitability.

Quality control measures and certifications at the refinery

Quality control is an essential aspect of the refining process at Wigmore Trading, Nigeria’s top refinery. It ensures that the end product meets high standards and is safe for use in various industries. The refinery follows strict quality control measures to maintain consistency and reliability in its gold production.

One of the main quality control measures at Wigmore Trading is regular testing of raw materials before they enter the refining process. This involves analyzing samples from each batch to ensure they meet the purity requirements for gold refining. Only certified assay labs are used for this purpose, and all results are carefully recorded and monitored.

Once the raw materials have been tested and approved, they are then processed through a series of stages, each with their own set of quality checks. These include melting, thermal processing, chemical treatment, and electrolysis. At every step, samples are taken and analyzed to ensure that impurities are being removed effectively and that the final product will be of high quality.

The refinery also has a team of highly trained experts who oversee all aspects of production and conduct thorough inspections throughout the entire process. They check for any irregularities or deviations from standard procedures to ensure that all operations are within acceptable limits. If any issues arise during these inspections, immediate corrective action is taken to prevent potential problems with the final product.

Apart from internal quality control measures, Wigmore Trading also holds various certifications that demonstrate its commitment to producing refined gold of exceptional quality. These certifications include ISO 9001:2015 (Quality Management System), ISO 14001:2015 (Environmental Management System), OHSAS 18001:2007 (Occupational Health & Safety Management System), as well as several others related to environmental sustainability and responsible sourcing.

These certifications not only serve as proof of complying with international standards but also provide confidence to customers in regards to the quality and ethical practices employed by Wigmore Trading. They also demonstrate a commitment towards continuous improvement in both processes and environmental stewardship.

Quality control is at the core of Wigmore Trading’s refining process. Through rigorous testing, expert oversight, and internationally recognized certifications, the refinery ensures that its refined gold meets the highest standards of purity and safety. This dedication to quality has made Wigmore Trading a trusted name in the gold refining industry in Nigeria and beyond.

Impact of Wigmore’s refinery on the local economy and community

The establishment of Wigmore Trading’s refinery has had a significant impact on the local economy and community in Nigeria. This state-of-the-art facility, located in the heart of Lagos, has not only transformed the process of refining raw materials into gold but also contributed to the growth and sustainability of the surrounding areas.

One of the most notable impacts of Wigmore’s refinery is its contribution to employment generation in the local community. The refinery employs a large number of skilled workers, technicians, and engineers who are trained in modern refining techniques. This has not only created job opportunities for locals but also provided them with valuable skills and knowledge that can be utilized in various industries.

Moreover, the refinery has also boosted economic growth by creating a demand for various ancillary services such as transportation, catering, and maintenance. Local businesses have benefited from this increased demand and have seen a considerable rise in their profits. Additionally, with an increase in income levels due to employment opportunities at Wigmore’s refinery, residents have more disposable income which leads to an overall improvement in their standard of living.

With regards to the local community, Wigmore Trading has been actively involved in several social responsibility initiatives aimed at improving the lives of people living near the refinery. The company has invested in building schools and healthcare facilities for children and families residing nearby. These initiatives not only provide access to education and healthcare but also create a sense of belonging within the community.

Furthermore, Wigmore’s presence has attracted other businesses into setting up operations nearby. The resulting industrialization has led to further economic development through increased trade activities and investment opportunities. As a result, there has been an overall improvement in infrastructure such as roads, electricity supply, water supply systems which benefits both locals and businesses alike.

In addition to these economic impacts, Wigmore Trading’s commitment towards sustainable practices has had a positive effect on the environment as well as promoting responsible mining practices within Nigeria. The company follows strict environmental regulations and employs advanced technologies to minimize the impact on the environment. This not only ensures a cleaner and healthier environment for the local community but also contributes to the sustainable development of the region.

Wigmore’s refinery has been a game-changer for the local economy and community in Nigeria. Its contributions through job creation, economic growth, social responsibility initiatives, and sustainable practices have made it an invaluable asset to the surrounding areas. As Nigeria continues to develop its mining industry, Wigmore Trading sets an example of responsible and ethical practices that can bring about positive change in both economic and social aspects.

Challenges faced by the company and how they are overcome

Wigmore Trading, being the top refinery in Nigeria, has faced its fair share of challenges throughout its journey towards refining gold. These obstacles have come in various forms and have tested the resilience and determination of the company. However, through strategic planning and effective problem-solving techniques, Wigmore Trading has successfully overcome these challenges to reach its current position as a leading refinery.

One of the major challenges faced by Wigmore Trading is the fluctuation of gold prices in the global market. Gold prices are affected by various factors such as economic conditions, political instability, and demand from other industries. As a result, it becomes challenging for Wigmore Trading to plan ahead for production and pricing. To overcome this challenge, the company has implemented an efficient risk management system that continuously monitors market trends and makes necessary adjustments to mitigate potential losses.

Another significant obstacle encountered by Wigmore Trading is the availability of raw materials. Due to its geographical location, Nigeria does not have a significant source of gold deposits. Therefore, acquiring enough raw materials for production can be difficult at times. To address this issue, Wigmore Trading has established partnerships with mining companies in neighboring countries to ensure a steady supply of raw materials for refining.

Moreover, maintaining high-quality standards is crucial in any refinery business. However, ensuring consistent quality can be a daunting task due to variations in raw materials and human error during production processes. To maintain uncompromised quality control measures at all times, Wigmore Trading has invested heavily in advanced technology and equipment that minimizes human errors while also conducting regular inspections and audits.

Furthermore, like any other industry operating on a large scale basis, managing logistics can be quite challenging for Wigmore Trading. With numerous suppliers and customers across different regions within Nigeria and beyond borders, ensuring timely delivery or shipment can become complicated at times due to unforeseen circumstances such as weather conditions or transportation issues. The company overcomes this challenge by maintaining strong communication channels with their partners and constantly monitoring the logistics process to minimize any delays.

Wigmore Trading has faced multiple challenges in its journey towards becoming a top refinery in Nigeria. However, through effective strategies and a dedicated team, the company has successfully overcome these obstacles and continues to thrive in the refining industry. By continuously adapting to changing market conditions and investing in advanced technology, Wigmore Trading remains at the forefront of refining gold in Nigeria.

–

The Process at Nigeria’s Top Refinery: Step by Step

Wigmore Trading, Nigeria’s leading gold refinery, has established itself as a major player in the country’s gold industry. With state-of-the-art technology and highly skilled professionals, Wigmore Trading prides itself on its efficient and sustainable refining process. But what exactly goes into turning raw materials into refined gold? In this section, we will take a closer look at the step-by-step process that takes place at Wigmore Trading.

Step 1: Receiving and Assaying Raw Materials

The first step in the refining process at Wigmore Trading is the receipt of raw materials. These include crude or unrefined gold bars, nuggets, scrap jewelry, and other forms of impure gold. Upon arrival at the refinery, these materials are subjected to rigorous testing and analysis through a process called assaying. This involves melting a small sample of the material and analyzing it for purity levels using advanced technology such as XRF spectrometers.

Step 2: Melting and Sampling

Once the materials have been assayed and their purity levels determined, they are ready to be melted down. The melting process involves heating the material in a furnace until it reaches its liquid form. The molten gold is then poured into molds to form bars for further processing. At this stage, samples are taken from each bar for further testing to ensure accuracy in the refining process.

Step 3: Chemical Treatment

After sampling, the molten gold is then subjected to chemical treatment to remove any impurities that may still be present. The most common technique used is electrolysis – passing an electric current through the molten gold – which causes impurities like silver and copper to settle at the bottom of the container while pure gold rises to the surface.

Step 4: Solidification and Cooling

Once all impurities have been removed from the molten gold, it is then solidified and cooled to form bars of pure gold. These bars are then weighed, measured, and stamped with Wigmore Trading’s hallmark for quality assurance.

Step 5: Final Assaying

Before the refined gold is ready for sale, it undergoes a final round of assaying to ensure that it meets international standards for purity. This involves analyzing samples from each bar using industry-standard techniques such as fire assay or atomic absorption spectroscopy.

Step 6: Packaging and Delivery

The final step in the refining process at Wigmore Trading is the packaging and delivery of the refined gold to its customers. The bars are carefully packaged and sent out with proper documentation to ensure traceability and accountability.

Wigmore Trading’s refining process follows strict guidelines and procedures to guarantee high-quality refined gold for its customers. From receiving raw materials to delivering the final product, every step is meticulously carried out by a team of experts committed to upholding the refinery’s reputation as Nigeria’s top refinery.

Comments are closed.