HDPE Injection Molding: Applications, Benefits, and Sourcing at Scale

High-density polyethylene (HDPE) injection molding plays a critical role in modern manufacturing, particularly across FMCG, packaging, industrial goods, and logistics sectors. Its durability, chemical resistance, and cost efficiency make it a preferred material for producing high-volume plastic components used across global supply chains.

For importers, distributors, and manufacturers operating in Africa and international markets, understanding how HDPE injection molding works—and how to source it reliably—can improve product quality, reduce costs, and ensure regulatory compliance.

What Is HDPE Injection Molding?

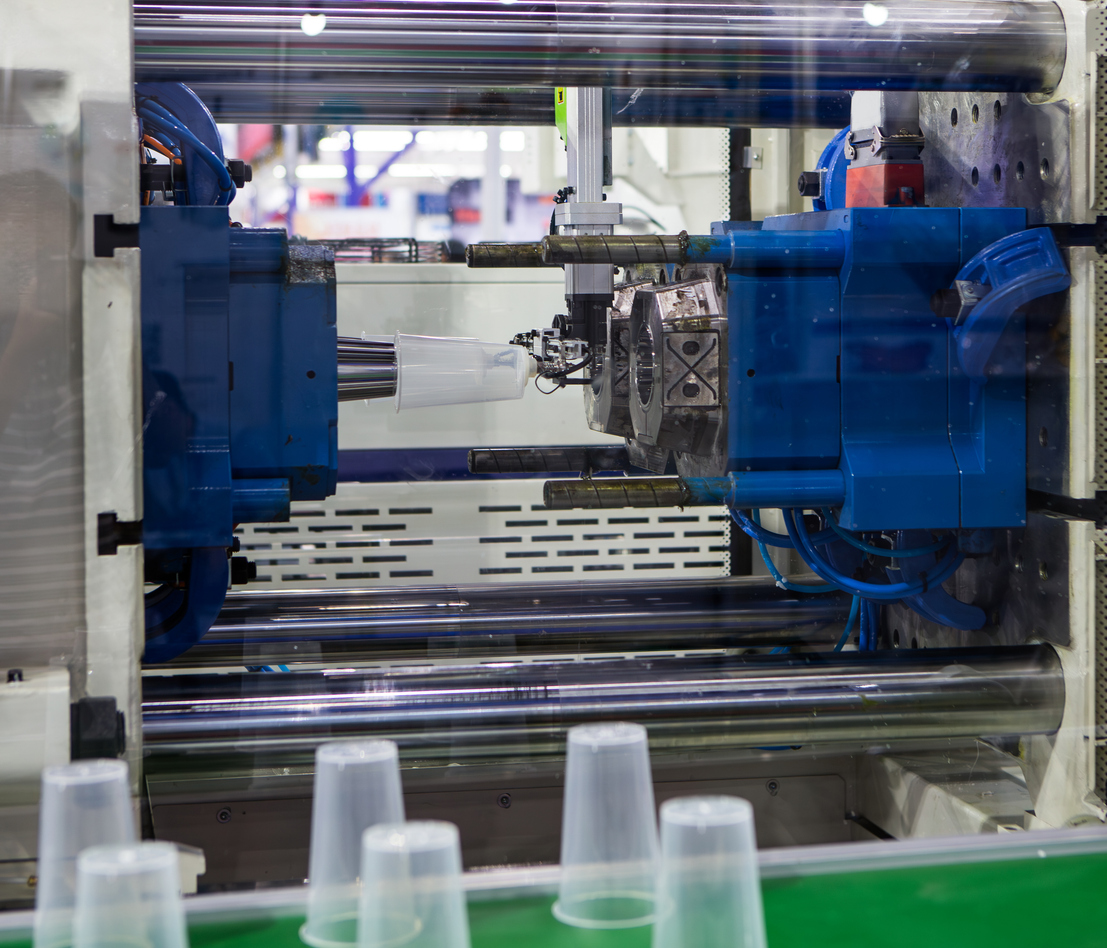

HDPE injection molding is a manufacturing process where molten high-density polyethylene is injected into a mold cavity under high pressure, cooled, and solidified into a finished part. The process is well-suited for mass production of uniform, complex plastic components with tight tolerances.

HDPE itself is a thermoplastic polymer known for its:

-

High strength-to-density ratio

-

Resistance to moisture, chemicals, and impact

-

Lightweight yet rigid structure

-

Recyclability and food-safe properties

These characteristics make HDPE injection molding ideal for products that must perform reliably in demanding environments.

Common Applications of HDPE Injection Molding

HDPE injection molded products are used across multiple industries, including:

FMCG and Packaging

-

Bottle caps and closures

-

Food containers and lids

-

Household product components

Industrial and Logistics

-

Crates, pallets, and bins

-

Protective casings

-

Industrial fittings and connectors

Agriculture and Infrastructure

-

Irrigation components

-

Storage containers

-

Pipe fittings

In African markets, HDPE injection molding is particularly valuable due to its durability in high temperatures and resistance to corrosion, making it suitable for both urban and rural applications.

Key Benefits of HDPE Injection Molding

Cost-Effective for High Volumes

Once molds are created, HDPE injection molding enables rapid, repeatable production at a low per-unit cost—ideal for large-scale distribution.

Consistent Quality

The process delivers uniform parts with consistent dimensions, which is critical for packaging, logistics, and industrial compatibility.

Chemical and Moisture Resistance

HDPE performs well in environments exposed to chemicals, humidity, and frequent handling, reducing product failure rates.

Lightweight and Durable

HDPE parts reduce shipping costs while maintaining structural strength—an advantage for exporters and importers managing logistics expenses.

Sustainable and Recyclable

HDPE is widely recyclable, helping businesses meet sustainability goals and comply with environmental standards.

Challenges in Sourcing HDPE Injection Molded Products

Despite its advantages, businesses often face challenges such as:

-

Inconsistent material quality

-

Long lead times from overseas manufacturers

-

Compliance with food-grade or industrial standards

-

Limited supplier transparency

-

Logistics and customs delays

These issues can disrupt supply chains and increase operational risk—especially for companies sourcing at scale.

How Wigmore Trading Supports HDPE Injection Molding Supply Chains

Wigmore Trading works with vetted manufacturers and suppliers to help businesses source high-quality HDPE injection molded products reliably and efficiently.

By leveraging strong supplier networks and logistics expertise, Wigmore Trading can help with:

-

Sourcing food-grade and industrial-grade HDPE components

-

Managing bulk procurement for wholesale and distribution

-

Ensuring quality control and specification compliance

-

Coordinating international shipping and African market logistics

For companies expanding into new markets or optimizing existing supply chains, Wigmore Trading can help reduce sourcing risk and improve cost predictability without adding unnecessary complexity.

Choosing the Right HDPE Injection Molding Partner

When selecting a supplier or sourcing partner, businesses should consider:

-

Material certifications and compliance standards

-

Production capacity and consistency

-

Experience with export and cross-border trade

-

Logistics and documentation support

Working with an experienced trade partner helps ensure that HDPE injection molded products arrive on time, meet specifications, and integrate smoothly into downstream operations.

Wigmore Trading can help businesses navigate these considerations and connect with reliable manufacturing and distribution solutions tailored to their industry needs.

Conclusion

HDPE injection molding remains a cornerstone of modern manufacturing due to its versatility, durability, and cost efficiency. From FMCG packaging to industrial logistics and agricultural infrastructure, its applications continue to grow across African and global markets.

For businesses seeking dependable sourcing, quality assurance, and efficient delivery, partnering with an experienced trade facilitator is essential.

Get in touch with our team to learn more about how Wigmore Trading can support your HDPE injection molding supply requirements.

Comments are closed.