How Contract Manufacturing in Nigeria Can Transform Your Business

Contract manufacturing in Nigeria has become a crucial strategy for businesses aiming to expand efficiently while reducing production costs. Companies across sectors such as FMCG, pharmaceuticals, and consumer electronics increasingly rely on contract manufacturing partners to handle production, packaging, and quality control. By outsourcing these functions, businesses can focus on core activities like marketing, distribution, and innovation while leaving the complex logistics and compliance to experts.

Understanding Contract Manufacturing in Nigeria

Contract manufacturing involves outsourcing production processes to a third-party manufacturer. In Nigeria, this approach allows businesses to scale operations without investing heavily in factory infrastructure, machinery, or labor. The practice is especially beneficial for small and medium enterprises (SMEs) looking to enter the market quickly, meet demand spikes, or expand product lines without significant upfront capital.

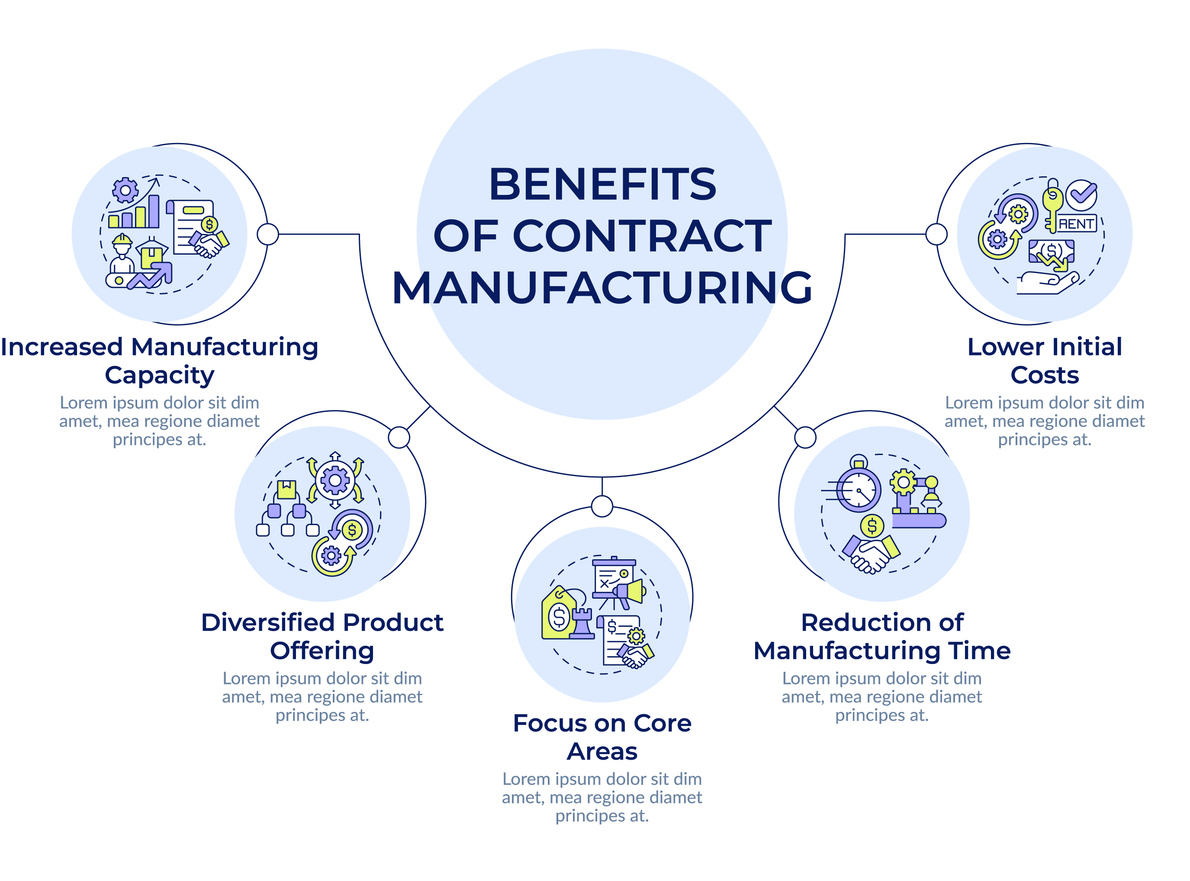

Advantages of Contract Manufacturing

-

Cost Efficiency

Setting up a full-scale manufacturing facility can be prohibitively expensive. Partnering with an experienced contract manufacturer in Nigeria reduces overhead costs, including labor, machinery, and utilities. -

Access to Expertise

Established contract manufacturers offer specialized knowledge in quality control, compliance, and production processes, ensuring that products meet both local and international standards. -

Flexibility and Scalability

Businesses can scale production volumes up or down based on market demand. This flexibility is essential for seasonal products or industries with fluctuating consumer needs. -

Speed to Market

By leveraging existing production facilities, companies can launch new products faster, gaining a competitive edge in dynamic markets.

Choosing the Right Contract Manufacturing Partner in Nigeria

Selecting the right partner is critical for operational efficiency and brand reputation. Businesses should evaluate potential manufacturers based on:

-

Production capacity and capabilities

-

Quality assurance and regulatory compliance

-

Reliability in meeting deadlines

-

Transparent pricing and contractual terms

Wigmore Trading specializes in connecting businesses with reputable contract manufacturing partners across Nigeria. Our network ensures that your products are manufactured to the highest standards, on time, and at competitive rates.

Common Challenges in Contract Manufacturing and How to Overcome Them

Quality Control

Maintaining product quality is often the top concern. Wigmore Trading can help implement rigorous quality checks and partner with manufacturers that adhere to ISO standards, GMP guidelines, or industry-specific regulations.

Communication Barriers

Misaligned expectations can cause delays or errors. Clear contracts, regular reporting, and our project management support ensure smooth communication throughout the production process.

Supply Chain Disruptions

Raw material shortages or logistics challenges can affect production. Wigmore Trading’s extensive network and logistics expertise mitigate risks, ensuring consistent supply and timely delivery.

Why Partner with Wigmore Trading

At Wigmore Trading, we provide end-to-end support for businesses seeking contract manufacturing in Nigeria. From identifying reliable partners to managing production schedules and logistics, we ensure your operations are streamlined and efficient. Our practical solutions help companies reduce costs, improve quality, and accelerate time to market.

Whether you’re looking to manufacture FMCG products, pharmaceutical goods, or industrial materials, Wigmore Trading can help you navigate the complexities of contract manufacturing in Nigeria with confidence.

Comments are closed.