How HDPE Injection Molding Powers Scalable, Cost-Efficient Production

HDPE injection molding plays a critical role in modern manufacturing, particularly across industries such as FMCG, packaging, agriculture, construction, and logistics. Known for its durability, cost efficiency, and versatility, High-Density Polyethylene (HDPE) is one of the most widely used thermoplastics in injection molding applications.

For businesses sourcing plastic components or finished products across Africa and international markets, understanding how HDPE injection molding works—and how to source it reliably—can significantly improve product quality and supply chain efficiency. Wigmore Trading can help companies navigate this process with trusted sourcing and logistics support.

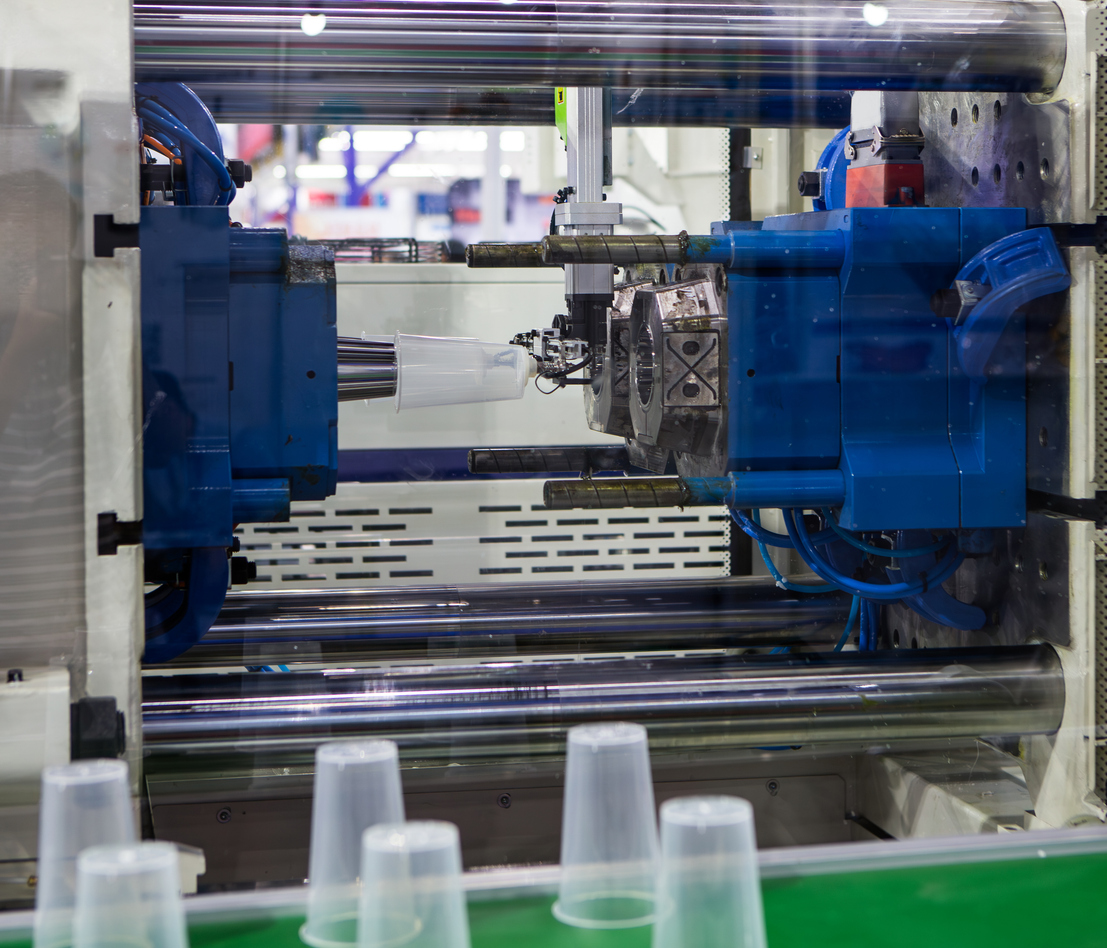

What Is HDPE Injection Molding?

HDPE injection molding is a manufacturing process where molten high-density polyethylene is injected into a mold to produce solid plastic parts. Once cooled, the mold opens and the finished product is ejected. This method is ideal for producing high volumes of uniform, high-strength components.

HDPE is particularly valued for its high strength-to-density ratio, chemical resistance, and impact resistance. These properties make HDPE injection molding suitable for products that must withstand harsh environments, repeated use, or exposure to moisture and chemicals.

Key Benefits of HDPE Injection Molding for Industrial Use

Durability and Strength

One of the main advantages of HDPE injection molding is durability. HDPE products resist cracking, corrosion, and impact damage, making them suitable for industrial containers, crates, caps, and protective components used in logistics and FMCG distribution.

Cost-Effective Mass Production

Injection molding allows manufacturers to produce large volumes at a relatively low unit cost. For businesses importing or distributing plastic products in African markets, HDPE injection molding offers a balance between affordability and long-term performance.

Chemical and Moisture Resistance

HDPE’s resistance to acids, solvents, and moisture makes it ideal for packaging chemicals, food-grade containers, and agricultural products. This is especially important in regions with high humidity or challenging storage conditions.

Design Flexibility

HDPE injection molding supports complex shapes and precise dimensions. Manufacturers can create customized components with consistent quality, which is essential for branded packaging and standardized industrial parts.

Common Applications of HDPE Injection Molding

HDPE injection molding is widely used across multiple sectors, including:

-

FMCG packaging such as bottle caps, closures, and containers

-

Industrial storage bins and crates

-

Agricultural products like irrigation fittings and seed containers

-

Household items including bins, buckets, and reusable containers

-

Logistics and supply chain components such as pallets and protective casings

For importers and wholesalers, sourcing these products from reliable manufacturers is key to maintaining consistent supply and quality.

Challenges in Sourcing HDPE Injection Molded Products

Despite its advantages, businesses often face challenges when sourcing HDPE injection molded products internationally. These include inconsistent material quality, unreliable suppliers, long lead times, and logistics bottlenecks.

Quality control is particularly important, as variations in HDPE resin grades can affect strength, flexibility, and product lifespan. Additionally, coordinating shipping, customs clearance, and local delivery can be complex without experienced trade support.

This is where Wigmore Trading can help by connecting businesses with vetted manufacturers and managing end-to-end sourcing and logistics.

How Wigmore Trading Supports HDPE Injection Molding Supply Chains

Wigmore Trading works with trusted manufacturers and suppliers to help businesses source HDPE injection molded products that meet international quality standards. Whether you need packaging components, industrial parts, or custom-molded items, Wigmore Trading can assist with supplier selection, quality assurance, and logistics coordination.

With deep experience in African trade and global import/export operations, Wigmore Trading helps reduce sourcing risks while ensuring timely delivery. Our team supports businesses across FMCG, wholesale distribution, construction, and logistics sectors.

If you are expanding into new markets or optimizing your supply chain, Wigmore Trading can help streamline your HDPE injection molding sourcing process.

Choosing the Right HDPE Injection Molding Partner

When selecting a supplier for HDPE injection molding, businesses should consider material quality, production capacity, compliance with safety standards, and logistics capabilities. Working with an experienced trade partner simplifies this process and helps avoid costly delays or quality issues.

Wigmore Trading can help businesses identify the right suppliers and manage procurement efficiently. Get in touch with our team to learn more about sourcing HDPE injection molded products for your business.

Final Thoughts

HDPE injection molding remains a dependable manufacturing solution for durable, cost-effective plastic products across multiple industries. As demand continues to grow in African and global markets, partnering with a knowledgeable sourcing and logistics provider is essential.

Contact Wigmore Trading today to streamline your sourcing and ensure reliable access to high-quality HDPE injection molded products.

Comments are closed.