How Injection Molded Polypropylene Supports Durable, Cost-Efficient Supply Chains

Injection molded polypropylene plays a critical role in modern manufacturing, packaging, and distribution. Its durability, cost efficiency, and versatility make it one of the most widely used thermoplastics across industries such as FMCG, automotive, healthcare, and industrial logistics. For importers, exporters, and wholesale buyers operating in African and international markets, understanding injection molded polypropylene is essential for making informed sourcing decisions.

This article explores what injection molded polypropylene is, its advantages, key applications, and how Wigmore Trading can support reliable sourcing and distribution.

What Is Injection Molded Polypropylene?

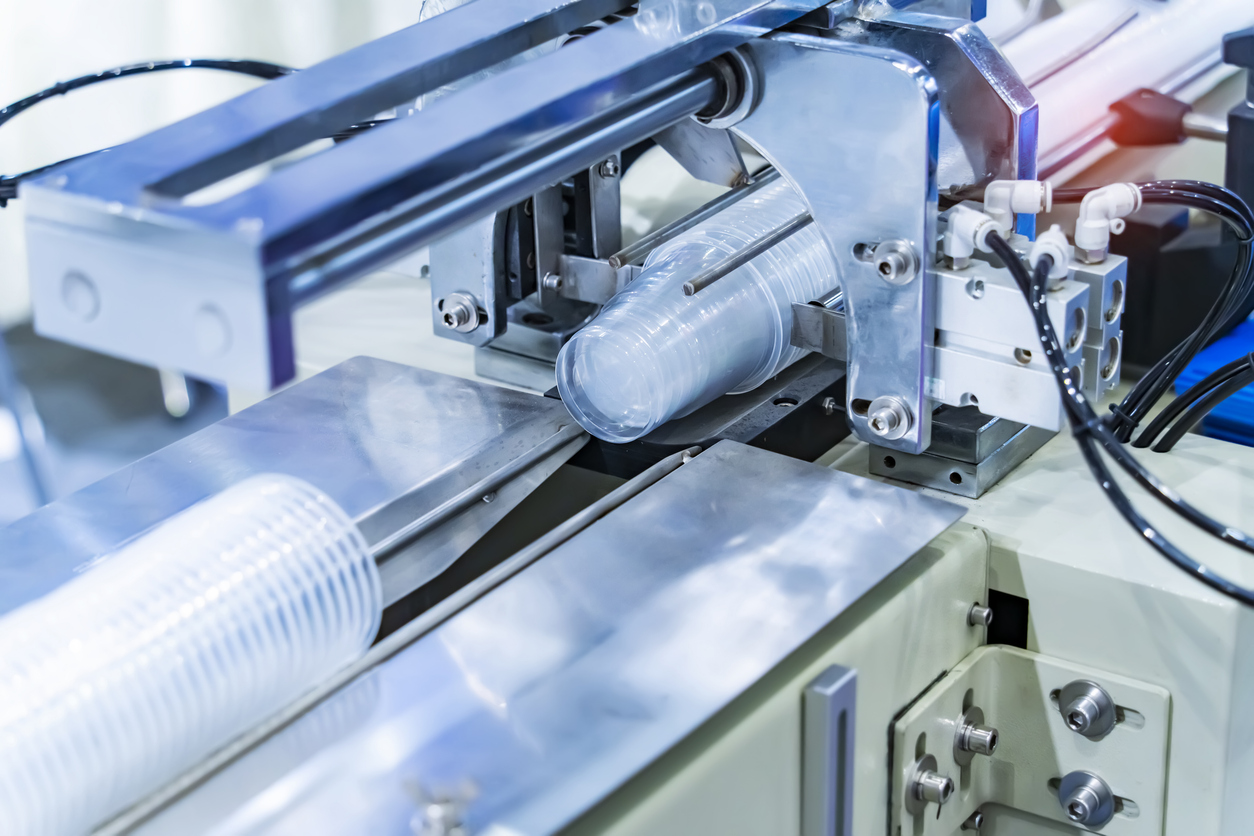

Injection molded polypropylene refers to polypropylene plastic components produced using the injection molding process. Polypropylene (PP) is a thermoplastic polymer derived from propylene monomers. During injection molding, molten polypropylene is injected into a mold, cooled, and solidified into precise shapes.

This process allows manufacturers to produce consistent, high-volume plastic parts with tight tolerances. Injection molded polypropylene is commonly used for items requiring strength, chemical resistance, and repeated use without deformation.

Key Properties of Injection Molded Polypropylene

Injection molded polypropylene is valued for a balance of performance and cost. Its properties make it suitable for a wide range of commercial and industrial uses.

Durability and Impact Resistance

Polypropylene offers excellent toughness and fatigue resistance. Injection molded polypropylene components can withstand repeated bending and impact, making them ideal for reusable containers, closures, and industrial parts.

Chemical and Moisture Resistance

Injection molded polypropylene resists many acids, alkalis, and solvents. This makes it a preferred material for chemical packaging, food containers, and pharmaceutical applications where material integrity is critical.

Lightweight and Cost-Effective

Compared to many engineering plastics, polypropylene is lightweight and economical. For import/export businesses, this reduces shipping costs while maintaining structural strength.

Thermal Stability

Injection molded polypropylene performs well across a wide temperature range. It maintains shape and function in both ambient and moderately high-temperature environments, which is important for storage and transport across diverse climates.

Common Applications of Injection Molded Polypropylene

Injection molded polypropylene is used across multiple sectors that Wigmore Trading serves.

FMCG and Food Packaging

Injection molded polypropylene is widely used for food containers, caps, lids, and trays due to its food-safe characteristics and moisture resistance. It supports high-volume FMCG distribution across African and global markets.

Industrial and Logistics Solutions

Reusable crates, pallets, bins, and storage components often rely on injection molded polypropylene. These products are designed for repeated handling, stacking, and transport in warehouses and supply chains.

Healthcare and Pharmaceutical Products

Syringes, specimen containers, and medical packaging frequently use injection molded polypropylene due to its chemical resistance and ability to meet hygiene standards.

Automotive and Consumer Goods

Interior automotive components, appliance housings, and household items benefit from injection molded polypropylene’s durability and design flexibility.

Injection Molded Polypropylene in Global Trade

For businesses involved in international sourcing, injection molded polypropylene offers supply chain advantages. It is produced at scale in major manufacturing hubs, making it widely available for bulk procurement.

However, challenges can arise in quality consistency, regulatory compliance, and logistics coordination—especially when sourcing for African markets. These challenges require experienced trade partners who understand cross-border requirements.

Sourcing Injection Molded Polypropylene Products with Confidence

When sourcing injection molded polypropylene products, buyers should consider:

-

Material grade and compliance standards

-

Mold quality and dimensional accuracy

-

Production capacity and lead times

-

Packaging and shipping durability

Working with a trusted trading partner helps mitigate risks related to inconsistent quality or delayed shipments.

Wigmore Trading can help by connecting buyers with vetted manufacturers and managing end-to-end logistics. With experience in wholesale distribution and African trade, Wigmore Trading supports businesses seeking reliable injection molded polypropylene solutions without unnecessary complexity.

Why Injection Molded Polypropylene Fits African Markets

Injection molded polypropylene products are particularly well-suited to African markets due to their durability, reusability, and cost efficiency. From FMCG packaging to agricultural storage and industrial handling, polypropylene-based products perform well in demanding environments.

Wigmore Trading understands local market needs, import regulations, and distribution challenges. By aligning sourcing strategies with regional requirements, Wigmore Trading helps businesses deploy injection molded polypropylene products effectively.

Practical Solutions for Businesses

Businesses facing supply chain disruptions, inconsistent product quality, or rising logistics costs can benefit from streamlined sourcing strategies. Injection molded polypropylene offers a scalable solution when paired with the right trade partner.

Wigmore Trading can help evaluate suppliers, coordinate shipments, and ensure products meet required specifications.

Get in touch with our team to learn more about sourcing injection molded polypropylene for your business.

Comments are closed.