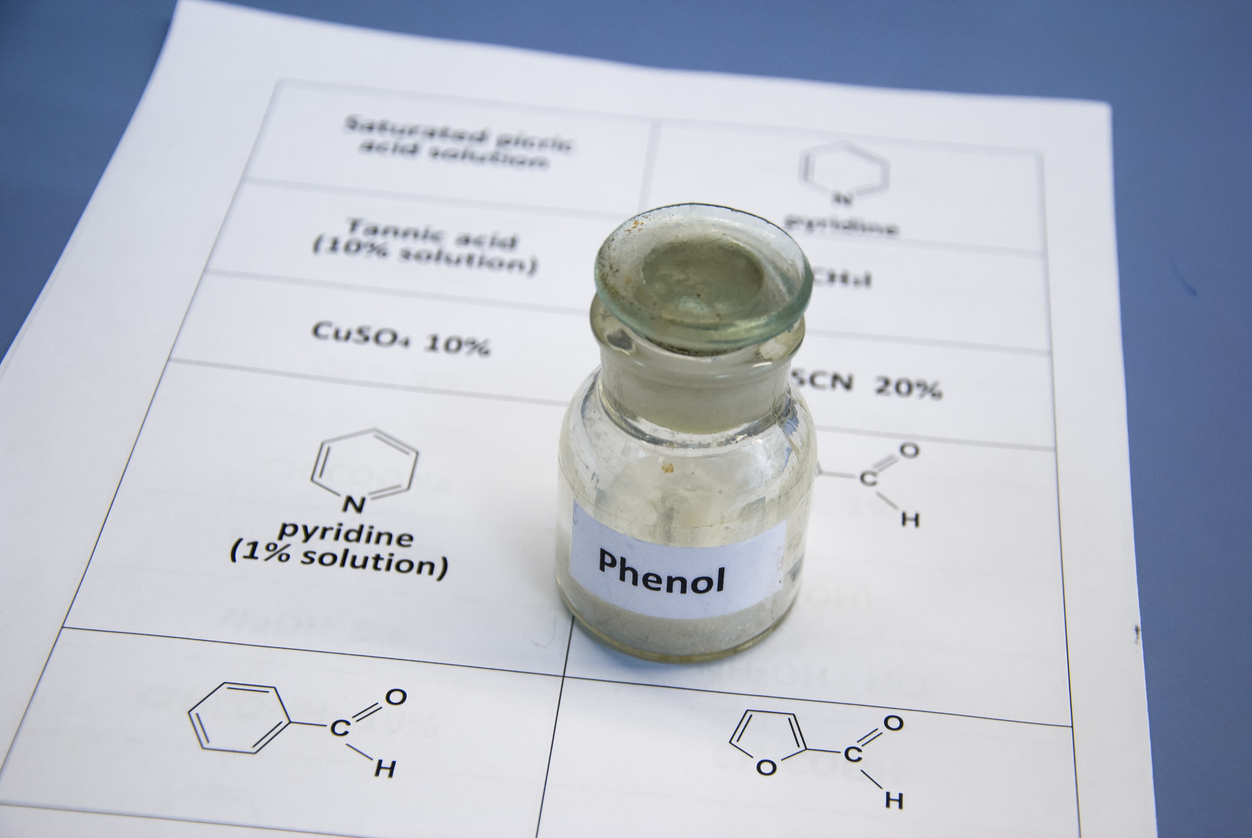

Phenol MSDS: Safety, Handling, and Compliance for Industrial Use

Phenol is a widely used industrial chemical found in pharmaceuticals, resins, plastics, disinfectants, dyes, and petrochemical applications. Due to its toxic and corrosive nature, understanding the Phenol MSDS (Material Safety Data Sheet) is critical for manufacturers, importers, distributors, and logistics providers handling this substance.

For businesses involved in chemical sourcing, bulk distribution, or international trade, proper MSDS documentation is not only a safety requirement—it is also a regulatory and operational necessity. Wigmore Trading supports companies across Africa and global markets by supplying compliant industrial chemicals, complete safety documentation, and reliable logistics solutions.

What Is a Phenol MSDS?

A Phenol MSDS is an official safety document that outlines the chemical’s properties, hazards, safe handling procedures, storage requirements, emergency response actions, and disposal guidelines.

It is required under international safety frameworks such as:

-

GHS (Globally Harmonized System)

-

OSHA Hazard Communication Standard

-

REACH (EU)

-

African chemical safety regulations

Any company involved in importing, storing, transporting, or using phenol must ensure the MSDS is accurate, current, and accessible to workers and regulators.

Key Information Found in a Phenol MSDS

1. Chemical Identification

The MSDS identifies phenol by:

-

Chemical name: Phenol

-

CAS Number: 108-95-2

-

Molecular formula: C₆H₅OH

This section also lists recommended uses and supplier details—critical for import/export documentation and customs clearance.

Wigmore Trading provides phenol with complete identification data suitable for cross-border trade and regulatory review.

2. Hazard Identification

Phenol is classified as highly hazardous, and the MSDS highlights key risks:

-

Toxic if swallowed, inhaled, or absorbed through skin

-

Causes severe skin burns and eye damage

-

Harmful to aquatic life

-

Can affect the central nervous system and organs with prolonged exposure

Clear hazard labeling and MSDS access help businesses reduce workplace incidents and remain compliant with occupational safety laws.

3. Composition and Purity

The Phenol MSDS details:

-

Concentration or purity level

-

Presence of stabilizers or impurities

This information is particularly important for pharmaceutical manufacturing, resin production, and chemical processing, where quality and formulation consistency matter.

Wigmore Trading works with verified manufacturers to ensure phenol purity meets industrial and regulatory requirements.

4. Safe Handling and Storage Guidelines

According to the Phenol MSDS, proper handling includes:

-

Use of PPE (chemical-resistant gloves, goggles, protective clothing)

-

Adequate ventilation

-

Avoidance of direct skin contact

-

No eating or drinking in handling areas

Storage recommendations include:

-

Cool, well-ventilated areas

-

Tightly sealed containers

-

Away from oxidizing agents and ignition sources

Wigmore Trading supports customers with safe chemical packaging, compliant labeling, and storage-ready supply solutions.

5. First Aid and Emergency Measures

A Phenol MSDS outlines critical emergency responses:

-

Skin contact: Immediate removal of contaminated clothing and prolonged washing with water

-

Eye exposure: Rinse cautiously with water for at least 15 minutes

-

Inhalation: Move to fresh air and seek medical attention

-

Ingestion: Do not induce vomiting; get medical help immediately

Having trained staff and accessible MSDS documentation significantly reduces the severity of chemical incidents.

6. Firefighting and Spill Response

Phenol is combustible at elevated temperatures. The MSDS provides guidance on:

-

Suitable extinguishing media (foam, dry chemical, CO₂)

-

Protective equipment for firefighters

-

Spill containment and cleanup procedures

For companies transporting phenol across borders or within African markets, proper spill response planning is essential. Wigmore Trading assists clients by aligning supply chains with international safety transport standards.

7. Transport and Regulatory Compliance

The Phenol MSDS includes:

-

UN number (UN 1671)

-

Hazard class

-

Packing group

-

Transport restrictions for road, sea, and air freight

Accurate MSDS documentation prevents shipment delays, fines, and rejected cargo at ports. Wigmore Trading helps businesses navigate customs compliance, chemical import regulations, and safe international transport.

Why Phenol MSDS Matters for African and Global Trade

As chemical regulations tighten across Africa and international markets, buyers and distributors are under increasing pressure to demonstrate compliance.

A proper Phenol MSDS helps businesses:

-

Meet regulatory requirements

-

Protect workers and the environment

-

Reduce liability risks

-

Ensure smooth import/export operations

-

Maintain trust with partners and authorities

Wigmore Trading can help by supplying phenol with complete, up-to-date MSDS documentation, regulatory guidance, and reliable delivery across Africa and beyond.

Partnering with Wigmore Trading for Phenol Supply

Sourcing phenol from unreliable suppliers can lead to documentation gaps, safety risks, and costly disruptions. Wigmore Trading works with trusted manufacturers and logistics partners to deliver:

-

Industrial-grade phenol

-

Verified MSDS and safety documentation

-

Export-ready packaging

-

Regulatory-compliant logistics

-

Support for FMCG, pharmaceutical, chemical, and manufacturing industries

Contact Wigmore Trading today to streamline your phenol sourcing and compliance needs.

Comments are closed.