Polypropylene Acid Resistance: How It Performs in Chemical and Industrial Applications

Polypropylene (PP) is one of the most widely used thermoplastics in industrial and commercial applications. One of its most valuable properties is polypropylene acid resistance, which makes it suitable for use in harsh chemical environments across industries such as FMCG, pharmaceuticals, agriculture, water treatment, and manufacturing.

For importers, distributors, and manufacturers sourcing raw materials for African and international markets, understanding how polypropylene performs when exposed to acids is essential for product safety, durability, and regulatory compliance.

This guide explains how polypropylene resists acids, where it is commonly used, its limitations, and how Wigmore Trading can support reliable sourcing and supply.

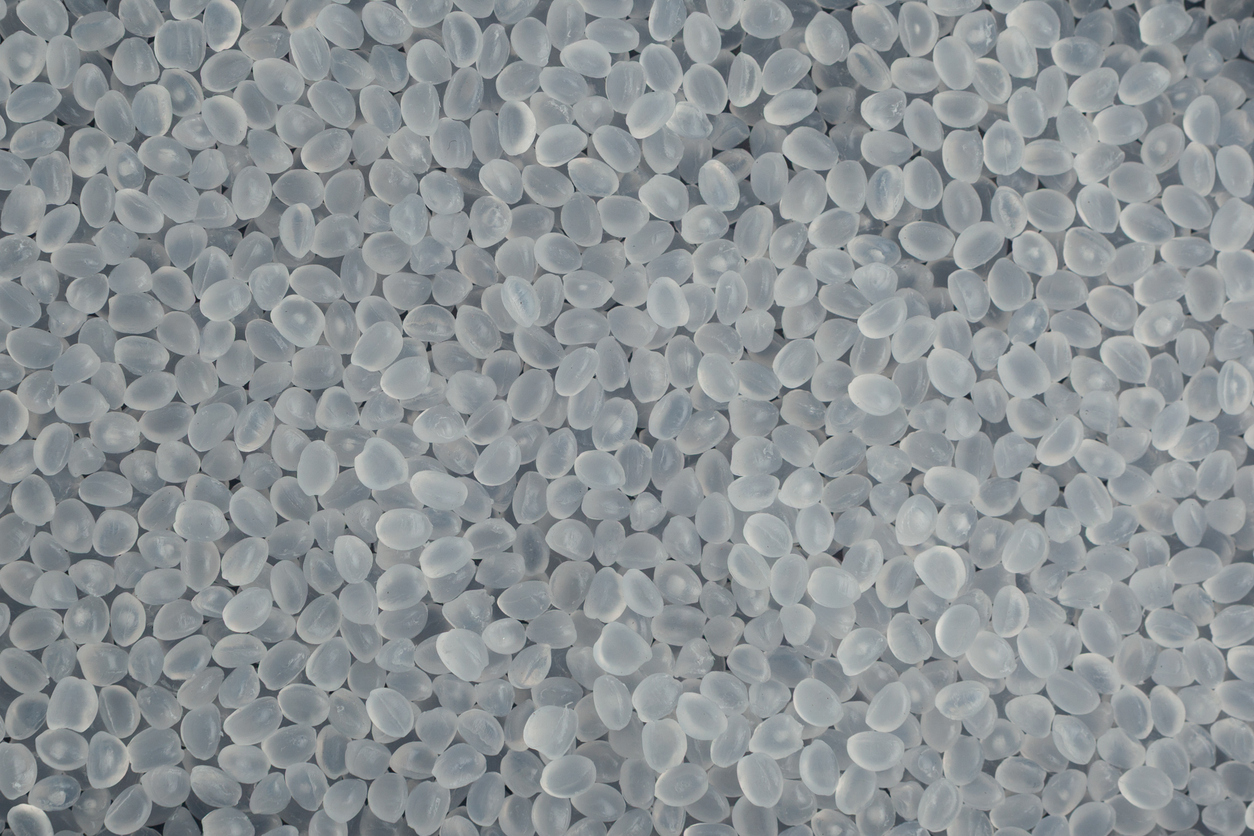

What Is Polypropylene?

Polypropylene is a thermoplastic polymer produced from propylene monomers. It is lightweight, strong, flexible, and cost-effective. These characteristics, combined with its chemical resistance, make it a preferred material for packaging, piping, containers, laboratory equipment, and industrial components.

Polypropylene is available in several forms, including homopolymer and copolymer grades, each offering slightly different mechanical and chemical properties depending on application requirements.

Understanding Polypropylene Acid Resistance

Why Polypropylene Resists Acids Well

Polypropylene’s molecular structure is non-polar and highly stable, meaning it does not easily react with many chemicals. This structure prevents acids from breaking down or degrading the polymer under normal operating conditions.

In practical terms, polypropylene acid resistance allows the material to withstand prolonged exposure to many inorganic and organic acids without significant loss of strength, flexibility, or surface integrity.

Acids Polypropylene Typically Resists

Polypropylene performs well when exposed to:

-

Sulfuric acid (low to moderate concentrations)

-

Hydrochloric acid

-

Nitric acid (at lower concentrations)

-

Phosphoric acid

-

Acetic acid and other weak organic acids

This makes PP a reliable choice for chemical handling, storage, and processing applications.

Common Applications That Rely on Polypropylene Acid Resistance

Chemical Storage and Transport

Polypropylene is widely used for:

-

Chemical drums and containers

-

Acid storage tanks

-

Laboratory bottles and beakers

Its resistance reduces the risk of leaks, contamination, and material failure during storage or transport.

Industrial Piping and Fittings

PP pipes and fittings are commonly used in:

-

Chemical processing plants

-

Water treatment facilities

-

Mining and agricultural chemical distribution

Compared to metals, polypropylene does not corrode, lowering maintenance costs and extending service life.

FMCG and Pharmaceutical Packaging

Many cleaning products, detergents, and pharmaceutical liquids contain acidic ingredients. Polypropylene packaging helps maintain product stability while preventing container degradation.

Automotive and Manufacturing Components

In automotive batteries, cooling systems, and industrial machinery, polypropylene parts are often exposed to acidic fluids, making chemical resistance a key requirement.

Limitations of Polypropylene in Acid Environments

While polypropylene acid resistance is strong, it is not universal. Buyers should consider the following limitations:

-

High-temperature exposure can reduce resistance, especially with strong acids

-

Highly concentrated oxidizing acids, such as concentrated nitric or chromic acid, can damage PP over time

-

Mechanical stress combined with chemical exposure may shorten product lifespan

Choosing the correct grade and thickness is critical. Wigmore Trading can help assess suitability based on your specific application and operating conditions.

Comparing Polypropylene to Other Plastics

When selecting materials for acidic environments, polypropylene is often compared to PVC, polyethylene (HDPE), and fluoropolymers.

-

Polypropylene vs PVC: PP offers better resistance to many acids and higher temperature tolerance

-

Polypropylene vs HDPE: PP generally performs better at elevated temperatures and against certain chemicals

-

Polypropylene vs PTFE: PTFE has superior chemical resistance but is significantly more expensive

For many cost-sensitive industrial and FMCG applications, polypropylene provides the best balance of performance and affordability.

Sourcing High-Quality Polypropylene for Acid-Resistant Applications

Quality consistency is critical when sourcing polypropylene for chemical resistance. Variations in resin grade, additives, and manufacturing standards can significantly affect performance.

Common sourcing challenges include:

-

Inconsistent resin quality

-

Unclear material specifications

-

Supply chain delays

-

Non-compliance with industry standards

This is where experienced sourcing partners add value.

How Wigmore Trading Supports Polypropylene Sourcing

Wigmore Trading works with trusted manufacturers and suppliers to provide high-quality polypropylene resins and finished products suitable for acid-resistant applications.

Our services support:

-

Verified polypropylene grades for chemical resistance

-

Reliable bulk supply for industrial, FMCG, and export markets

-

Logistics coordination across Africa and international trade routes

-

Guidance on material selection based on application requirements

By working with Wigmore Trading, buyers reduce sourcing risk while ensuring material performance and supply continuity. Wigmore Trading can help streamline your sourcing process and connect you with reliable polypropylene solutions.

Key Considerations Before Buying Polypropylene

Before placing orders, buyers should evaluate:

-

Type and concentration of acids involved

-

Operating temperature range

-

Mechanical stress during use

-

Compliance with food, pharmaceutical, or industrial regulations

Engaging with an experienced trading partner early can help prevent costly material failures or redesigns.

Final Thoughts

Polypropylene acid resistance makes it a versatile and dependable material for industries that operate in chemically demanding environments. From packaging and piping to industrial components, PP offers long-term durability, cost efficiency, and reliable performance when properly specified.

For importers, distributors, and manufacturers, sourcing the right polypropylene grade is just as important as understanding its chemical properties. Wigmore Trading can help ensure you receive consistent, application-ready polypropylene tailored to your market needs.

Get in touch with our team to learn more about sourcing polypropylene for acid-resistant applications. Contact Wigmore Trading today to streamline your sourcing.

Comments are closed.