Polypropylene Injection Molding Temperature: A Practical Guide for Manufacturers

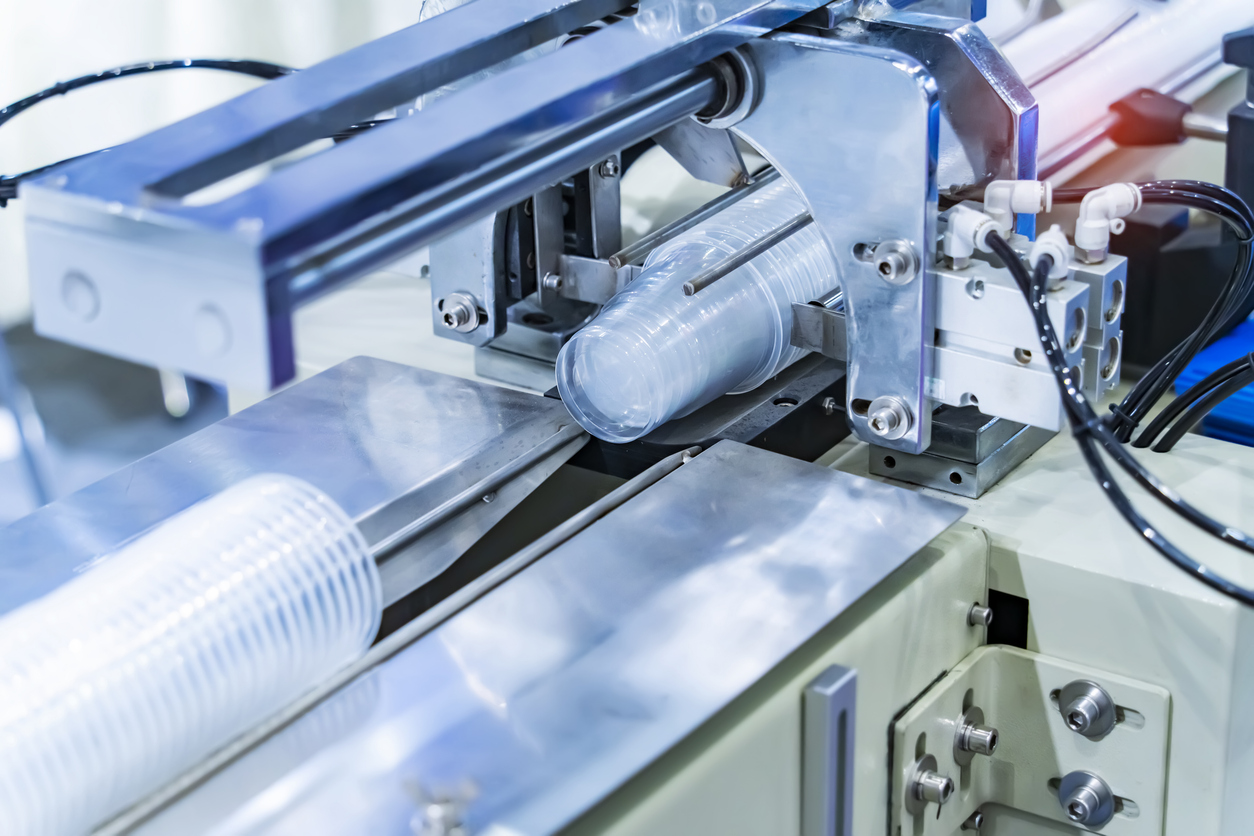

Polypropylene (PP) is one of the most widely used thermoplastics in injection molding, valued for its durability, chemical resistance, and cost efficiency. However, achieving consistent quality depends heavily on controlling the polypropylene injection molding temperature. For manufacturers, importers, and distributors working with plastic components—especially in FMCG packaging, automotive parts, and industrial goods—understanding the correct temperature range is essential to avoid defects and production losses.

Wigmore Trading works with manufacturers and buyers across Africa and global markets, supporting the sourcing and distribution of polypropylene materials and molded products that meet industry standards.

Why Polypropylene Injection Molding Temperature Matters

Injection molding temperature directly affects how polypropylene flows, fills the mold, and solidifies. If the temperature is too low, the material may not flow properly, leading to incomplete fills or weak parts. If it is too high, polypropylene can degrade, causing discoloration, odor, or reduced mechanical strength.

For businesses involved in large-scale production or international trade, temperature-related defects can mean rejected shipments, delayed timelines, and higher costs. Proper temperature control helps ensure consistency, durability, and compliance with buyer specifications.

Typical Polypropylene Injection Molding Temperature Range

The recommended polypropylene injection molding temperature generally falls within these ranges:

-

Barrel temperature: 180°C to 280°C

-

Melt temperature: 200°C to 250°C

-

Mold temperature: 20°C to 80°C

These values can vary depending on the grade of polypropylene, additives, and the final application. Homopolymer PP often requires slightly higher temperatures than copolymer PP due to its higher stiffness and melting point.

When sourcing polypropylene resin or molded products, Wigmore Trading can help buyers identify suitable material grades that align with their processing conditions and end-use requirements.

Key Factors That Influence Injection Molding Temperature

Several variables affect the ideal temperature setting for polypropylene injection molding:

Material grade and additives

Different PP grades—such as impact-modified or glass-filled polypropylene—require different melt temperatures. Fillers and colorants can also alter flow behavior.

Part design and wall thickness

Thin-walled parts usually need higher melt temperatures to ensure smooth flow, while thicker components may require lower temperatures to prevent sink marks and warping.

Injection speed and pressure

Higher injection speeds can generate shear heat, allowing for slightly lower barrel temperatures. Conversely, slower speeds may require higher set temperatures.

Mold cooling system

Efficient mold cooling allows better control over crystallization and shrinkage, especially important for high-volume production.

Understanding these factors helps manufacturers optimize processes and reduce waste. Wigmore Trading supports clients by connecting them with reliable polypropylene suppliers and molded product manufacturers who follow proven processing standards.

Common Problems Caused by Incorrect Polypropylene Injection Molding Temperature

Improper temperature control can lead to several production issues:

-

Short shots: Melt temperature too low, preventing complete mold filling

-

Warping and shrinkage: Uneven cooling or incorrect mold temperature

-

Burn marks or discoloration: Excessively high melt temperature

-

Reduced impact strength: Thermal degradation of polypropylene

These problems can be costly, particularly for exporters shipping to African or international markets where quality inspections are strict. Working with experienced material suppliers and logistics partners helps minimize these risks.

Best Practices for Controlling Polypropylene Injection Molding Temperature

To achieve stable and repeatable results, manufacturers should adopt the following practices:

Use consistent material sourcing

Switching between polypropylene suppliers or grades without adjusting temperature settings often leads to defects. Wigmore Trading can help businesses maintain consistent supply chains for PP resin and molded goods.

Monitor actual melt temperature

Machine set temperatures may differ from the real melt temperature. Using melt probes provides more accurate control.

Optimize mold temperature control

Stable mold temperatures improve surface finish and dimensional accuracy, especially for packaging and consumer products.

Conduct trial runs before mass production

Testing temperature ranges during initial runs helps identify the optimal window for each product.

These steps are especially important for companies producing components for FMCG, construction, and industrial applications across African markets.

Polypropylene Injection Molding Temperature in African Manufacturing and Trade

As manufacturing capacity expands across Africa, demand for polypropylene products continues to grow. From food containers and household goods to automotive parts and medical supplies, injection-molded PP plays a key role.

However, many importers and distributors face challenges related to inconsistent quality from overseas suppliers. Temperature mismanagement during molding is a common root cause. Wigmore Trading helps bridge this gap by sourcing from vetted manufacturers and ensuring products meet required specifications before shipment.

How Wigmore Trading Can Support Your Polypropylene Needs

Wigmore Trading works closely with manufacturers, wholesalers, and exporters to support polypropylene sourcing, molded product supply, and logistics across Africa and beyond. Whether you need raw polypropylene resin or finished injection-molded components, our team helps ensure quality, consistency, and reliable delivery.

If temperature-related defects or supply inconsistencies are affecting your business, Wigmore Trading can help.

Get in touch with our team to learn more about sourcing dependable polypropylene solutions tailored to your market.

Blog Title: Polypropylene Injection Molding Temperature Explained

Meta Title: Polypropylene Injection Molding Temperature Guide

Meta Description: Learn the ideal polypropylene injection molding temperature range and how to avoid defects in PP manufacturing.

Focus Keyphrase: polypropylene injection molding temperature

Slug: polypropylene-injection-molding-temperature

Meta Description (135 characters): Understand polypropylene injection molding temperature ranges and best practices to reduce defects and improve product quality.

Tags: polypropylene injection molding, injection molding temperature, polypropylene processing, plastic manufacturing, African trade, FMCG packaging, Wigmore Trading

Comments are closed.