Polypropylene Manufacturers in USA: A Guide for Global Buyers

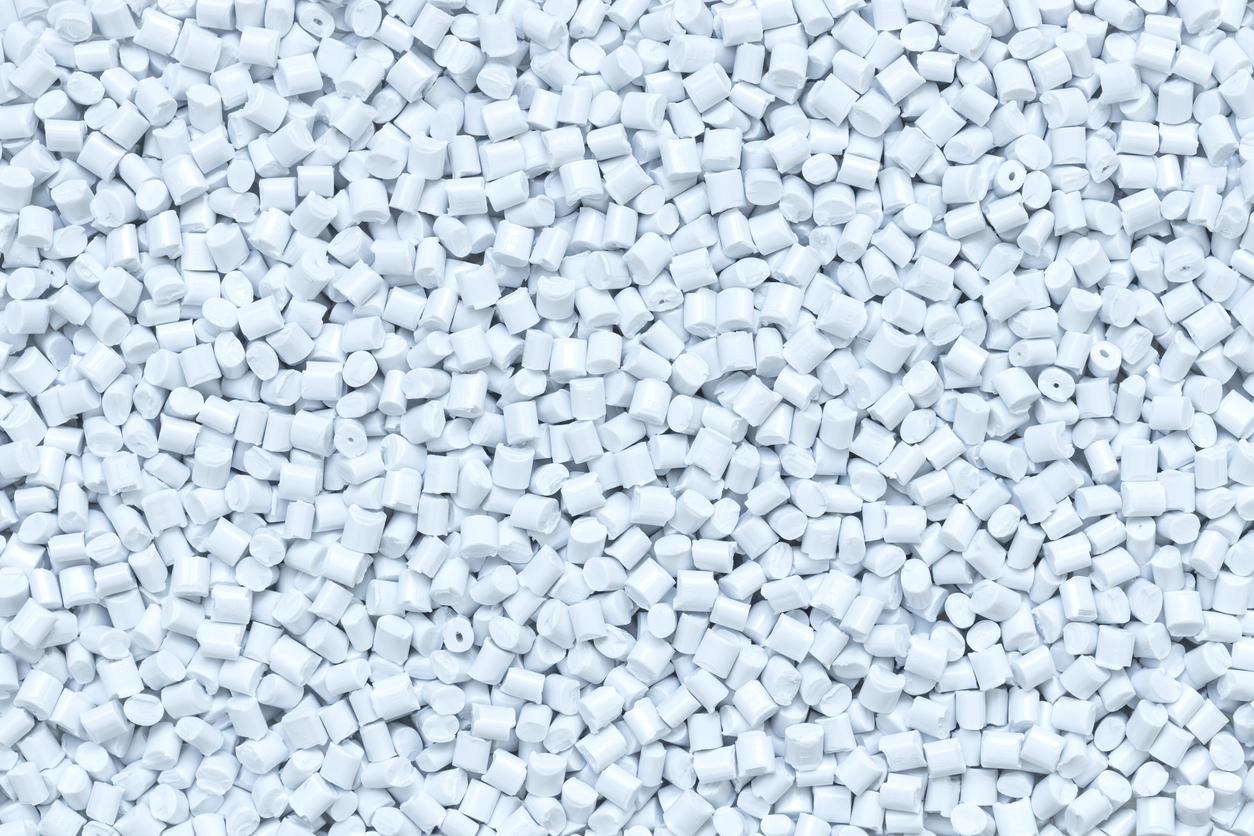

Polypropylene is one of the most widely used thermoplastics in the world, valued for its durability, chemical resistance, and cost efficiency. For importers, distributors, and manufacturers, sourcing from polypropylene manufacturers in USA offers reliability, consistent quality, and compliance with international standards.

This article explores the U.S. polypropylene manufacturing landscape, key applications, sourcing challenges, and how Wigmore Trading can support global buyers—especially across Africa and emerging markets.

Understanding Polypropylene and Its Industrial Importance

Polypropylene (PP) is a lightweight polymer used extensively across industries such as:

-

Packaging and FMCG

-

Automotive components

-

Medical devices

-

Construction materials

-

Textiles and fibers

-

Household and industrial plastics

Its versatility, recyclability, and strength make it a preferred material for manufacturers seeking scalable and cost-effective solutions.

Why Source from Polypropylene Manufacturers in USA?

Sourcing from polypropylene manufacturers in USA is attractive for several reasons:

High Production Standards

U.S. manufacturers adhere to strict quality, safety, and environmental regulations. This ensures consistent polymer properties, making U.S.-produced polypropylene suitable for regulated industries such as food packaging and healthcare.

Advanced Manufacturing Technology

American polypropylene producers invest heavily in modern polymerization technologies, offering a wide range of grades including:

-

Homopolymer polypropylene

-

Random copolymer polypropylene

-

Impact copolymer polypropylene

These options allow buyers to match exact performance requirements.

Reliable Supply Chains

Despite global disruptions, U.S. polypropylene production remains relatively stable due to strong domestic petrochemical infrastructure and access to feedstock.

Leading Polypropylene Manufacturers in USA

The U.S. market includes several globally recognized polypropylene producers supplying both domestic and international buyers. These companies typically serve large-scale industrial clients and distributors, offering bulk volumes and customized polymer grades.

However, working directly with manufacturers can present challenges for overseas buyers, including:

-

High minimum order quantities (MOQs)

-

Complex export documentation

-

Limited flexibility for mixed shipments

-

Longer negotiation cycles

This is where an experienced international trading partner becomes essential.

Key Industries Using U.S.-Made Polypropylene

Packaging and FMCG

Polypropylene is widely used in rigid containers, caps, films, and labels due to its moisture resistance and strength. FMCG manufacturers value its ability to preserve product integrity during transport.

Automotive and Industrial Manufacturing

U.S.-produced polypropylene meets demanding performance standards for automotive interiors, battery casings, and industrial components.

Healthcare and Medical Supplies

Medical-grade polypropylene from the USA is commonly used in syringes, pill containers, and sterile packaging, where material consistency is critical.

Challenges When Importing Polypropylene from the USA

While sourcing from polypropylene manufacturers in USA offers advantages, buyers often face practical obstacles:

-

Navigating export compliance and documentation

-

Managing shipping costs and lead times

-

Currency and payment complexities

-

Securing the right grade for local manufacturing needs

Without proper support, these issues can delay production and increase landed costs.

How Wigmore Trading Supports Polypropylene Sourcing

Wigmore Trading helps bridge the gap between U.S. polypropylene manufacturers and international buyers.

Access to Trusted Supply Networks

Wigmore Trading works with reliable polypropylene suppliers, ensuring consistent quality and verified sourcing. Buyers benefit from consolidated access rather than negotiating with multiple manufacturers.

Flexible Order Volumes

For buyers who do not require full-container loads, Wigmore Trading can help structure more flexible procurement solutions, including consolidated shipments.

End-to-End Logistics Support

From supplier coordination to export documentation and shipping, Wigmore Trading streamlines the entire process—reducing delays and compliance risks.

Market-Specific Expertise

With deep experience supporting African and emerging markets, Wigmore Trading understands regional regulations, port logistics, and distribution challenges.

If you are sourcing polypropylene for packaging, manufacturing, or distribution, Wigmore Trading can help simplify your supply chain.

Choosing the Right Polypropylene Grade

Selecting the right polypropylene grade is critical for performance and cost control. Buyers should consider:

-

Melt flow rate (MFR)

-

Impact resistance

-

Heat tolerance

-

Regulatory requirements (food or medical use)

Wigmore Trading assists buyers in matching technical specifications with suitable polypropylene grades sourced from U.S. manufacturers.

Final Thoughts

The demand for reliable plastic raw materials continues to grow, and polypropylene manufacturers in USA remain a trusted source for high-quality polymer solutions. However, successful sourcing requires more than identifying a supplier—it requires logistics expertise, market knowledge, and risk management.

Wigmore Trading supports importers, wholesalers, and manufacturers by providing access to trusted polypropylene supply, flexible sourcing options, and efficient global logistics.

Contact Wigmore Trading today to streamline your polypropylene sourcing from the USA.

Comments are closed.