Revolutionizing Manufacturing in Nigeria: The Rise of Additive Manufacturing with Wigmore Trading

Revolutionizing Manufacturing in Nigeria: The Rise of Additive Manufacturing with Wigmore Trading

Nigeria – the giant of Africa, is a country with immense potential. Over the years, it has been striving to become a hub for manufacturing and innovation. And now, with the rise of additive manufacturing technology through Wigmore Trading, Nigeria is on its way to revolutionizing its traditional methods of production. In this blog post, we’ll explore how Wigmore Trading is changing the game by introducing cutting-edge 3D printing solutions that are transforming the Nigerian market and paving the way towards a brighter future for all manufacturers in Nigeria. So let’s dive in!

Introduction to Additive Manufacturing

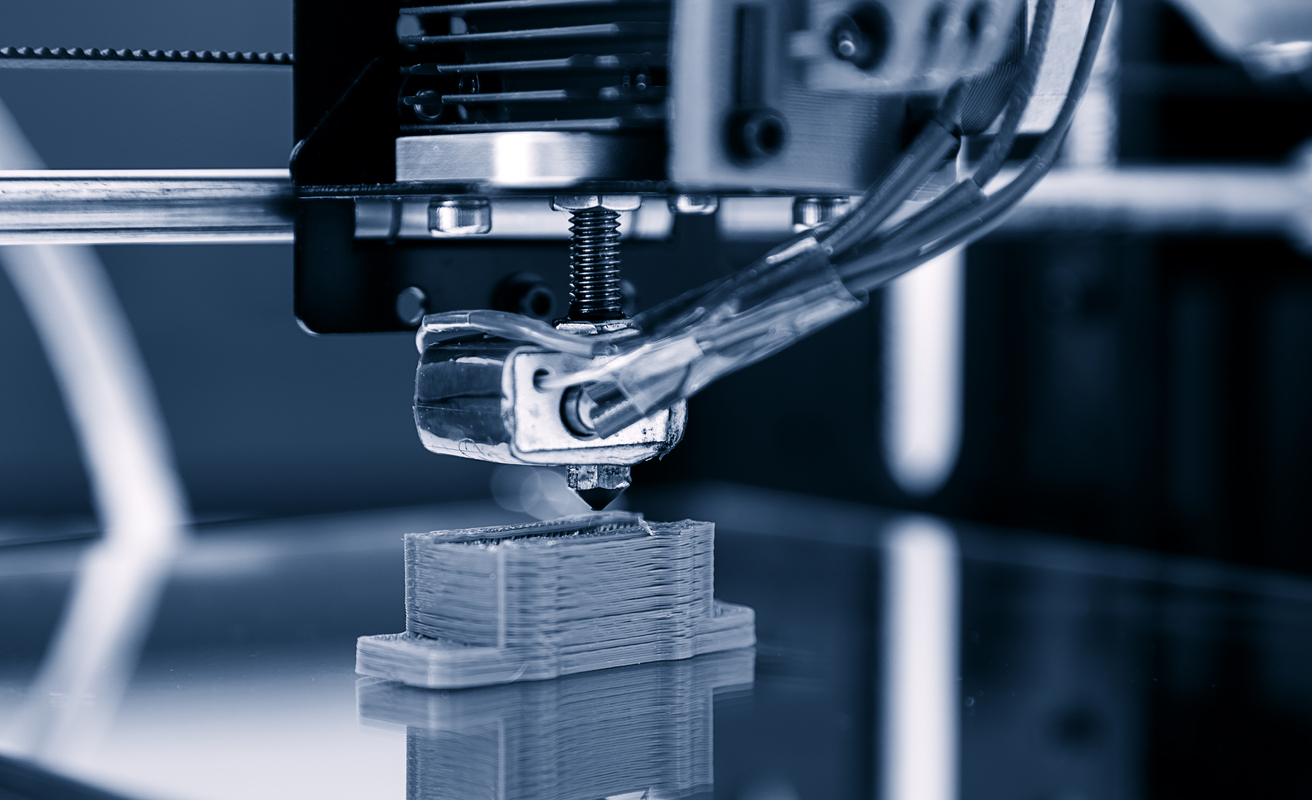

Additive Manufacturing (AM) is an umbrella term for a range of technologies that build objects by successively adding material layer-by-layer. Also known as 3D Printing, AM has been around since the 1980s but only recently started to gain significant traction in both the public and private sector due to its ability to quickly and cheaply produce prototypes and customised products.

In Nigeria, AM is still in its infancy but there are a number of companies that are beginning to explore its potential. One such company is Wigmore Trading, a leading provider of industrial machinery and equipment. Wigmore has been at the forefront of introducing new technologies to Nigeria and has been instrumental in helping businesses boost their productivity and competitiveness.

The company recently launched a new Additive Manufacturing division which offers 3D Printing services as well as training and support. This is a significant development as it will help businesses in Nigeria take advantage of this revolutionary technology.

Some of the benefits of additive manufacturing include:

– Reduced production costs: Additive manufacturing can be used to produce complex parts or products at a fraction of the cost of traditional manufacturing methods. This is because AM does not require expensive moulds or tooling, and there is no need for extensive assembly processes.

– Increased flexibility: With additive manufacturing, businesses can easily produce customised parts or products on-demand without incurring high set-up costs. This helps businesses save time and money while responding quickly to customer needs.

–

Benefits of Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a process of making three-dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes, where successive layers of material are laid down in different shapes. 3D printing is the opposite of subtractive manufacturing, which involves cutting away materials to create an object.

There are many benefits of additive manufacturing. One benefit is that it allows for the creation of complex objects that would be difficult or impossible to create using traditional manufacturing methods. Additive manufacturing also allows for the creation of customized objects. Another benefit is that it can be used to create prototypes quickly and cheaply. Additionally, additive manufacturing often requires less energy and generates less waste than traditional manufacturing methods.

Additive manufacturing is revolutionizing manufacturing in Nigeria and around the world. It has the potential to greatly increase productivity and reduce costs while providing businesses with new opportunities to create innovative products.

How Wigmore Trading is Revolutionizing the Nigerian Manufacturing Industry

Wigmore Trading is a Nigerian company that is helping to revolutionize the manufacturing industry in the country. The company has developed a technology called additive manufacturing, which allows for the production of products from raw materials without the need for traditional manufacturing processes. This new technology is already having a positive impact on the Nigerian economy, and it is expected to continue to do so in the future.

Wigmore Trading’s additive manufacturing technology is changing the way that products are made in Nigeria. With this new technology, products can be created from raw materials without the need for traditional manufacturing processes. This means that more products can be made in less time, and at a lower cost. As a result, Wigmore Trading is able to provide its customers with high-quality products at an affordable price.

In addition to its impact on the manufacturing industry, Wigmore Trading’s additive manufacturing technology is also benefiting the environment. Additive manufacturing produces very little waste, as there is no need to cut or shape material into specific shapes or sizes. This reduces the amount of pollution and resources that are used in traditional manufacturing processes.

Wigmore Trading’s additive manufacturing technology is having a positive impact on the Nigerian economy. The company’s products are helping to create jobs and boost economic growth. In addition, Wigmore Trading’s technology is helping to reduce poverty and improve living standards for people in Nigeria.

Challenges of Adopting 3D Printing in Nigeria

In Nigeria, as in many parts of the world, 3D printing is still in its infancy. The technology is not yet widely known or understood, and there are few trained professionals to operate and maintain 3D printers. The high cost of 3D printers and materials is also a barrier to adoption.

Despite these challenges, there are many reasons to be optimistic about the future of 3D printing in Nigeria. The technology is advancing rapidly and becoming more affordable. There are already a number of businesses and individuals using 3D printers to create products and prototypes. With continued support and investment, 3D printing could play a transformative role in Nigerian manufacturing.

Examples of Successful Projects by Wigmore Trading

Wigmore Trading has successfully completed numerous additive manufacturing projects in Nigeria. Some examples of these projects include:

-A project to produce metal parts for the Nigerian Air Force

-A project to produce medical implants for a hospital in Lagos

-A project to create prototypes for a new product line for a company in Abuja

Each of these projects has helped to revolutionize manufacturing in Nigeria by making it more efficient and cost-effective. Additive manufacturing has made it possible for Wigmore Trading to complete these projects quickly and efficiently, without sacrificing quality or accuracy.

Conclusion

Wigmore Trading’s introduction of additive manufacturing is revolutionizing the Nigerian manufacturing industry. This technology has allowed for greater efficiency, cost-effectiveness, and scalability. It also creates opportunities for local entrepreneurs to join in on the innovation. The possibilities are endless when it comes to unlocking Nigeria’s potential and making a positive impact on its economy through this new technology. With Wigmore Trading leading the way, we can look forward to seeing more growth in this sector as well as other developing countries around the world in the near future.

LEAVE A COMMENT

You must be logged in to post a comment.