The Future of Precision Engineering: A Look at Machining in Nigeria with Wigmore Trading

The Future of Precision Engineering: A Look at Machining in Nigeria with Wigmore Trading

Precision engineering is the backbone of modern innovation, driving advancements in technology and manufacturing processes. In Nigeria, one company is leading the charge towards a brighter future for machining: Wigmore Trading. Join us as we explore the cutting-edge world of precision engineering in Nigeria and discover how Wigmore Trading is shaping the industry’s landscape for years to come.

Introduction to Precision Engineering and Machining

Introduction to Precision Engineering and Machining

Precision engineering and machining are critical components of modern manufacturing processes. These techniques involve the use of specialized tools and equipment to create precise and accurate metal parts, components, and products. In today’s rapidly advancing technological landscape, precision engineering and machining have become even more crucial as they play a vital role in the development of innovative products.

Precision engineering is a sub-discipline of mechanical engineering that focuses on creating highly accurate components with tight tolerances. It involves using advanced computer-aided design (CAD) software to design parts before they are manufactured using precision machining techniques. This process allows for complex designs to be translated into tangible products with remarkable accuracy.

On the other hand, machining refers to the controlled removal of material from a workpiece using cutting tools such as drills, lathes, milling machines, or grinders. The aim is to shape the material into the desired form by removing excess material through cutting, drilling, turning, grinding or milling. Machining can also involve other processes like welding or soldering to join different materials together.

The combination of precision engineering and machining has revolutionized how we produce goods in various industries such as aerospace, automotive, medical devices, electronics, and many more. With increasing demand for high-quality products at competitive prices across different sectors worldwide has made precision engineering an integral part of global manufacturing processes.

Nigeria has not been left behind in this trend; there has been significant growth in precision engineering services over recent years due to the country’s rapid industrialization drive. Wigmore Trading – a leading supplier of quality industrial raw materials – recognized this opportunity early on and invested heavily in acquiring state-of-the-art machinery from renowned manufacturers worldwide.

Wigmore Trading’s precision engineering department is equipped with advanced CNC (Computer Numerical Control) machines that offer unrivaled accuracy while maintaining high productivity levels for both small scale production runs as well as mass production orders. Their skilled team of engineers and technicians continually strive for excellence, ensuring that their clients receive exceptional products and services.

Precision engineering and machining are crucial aspects of modern manufacturing, allowing for the production of complex designs with high levels of accuracy. With the increasing importance of these techniques in various industries globally, Nigeria’s industrial sector is also experiencing significant growth, thanks to companies like Wigmore Trading investing in state-of-the-art machinery and highly skilled personnel.

The Importance of Precision Engineering in Modern Industries

Precision engineering is a crucial aspect of modern industries, with its impact being felt in various sectors such as manufacturing, healthcare, aerospace, and automotive. It involves the design and production of precise components and products that meet strict specifications and tolerances using advanced technology and techniques. In this section, we will discuss the importance of precision engineering in modern industries and how it plays a significant role in shaping the future of machining in Nigeria.

One of the primary reasons why precision engineering is essential in modern industries is its ability to produce high-quality products with utmost accuracy. With advancements in technology, precision engineers can now create intricate designs and components with micron-level precision. This level of accuracy ensures that the final product meets all desired specifications, leading to improved performance and functionality. In today’s highly competitive market, where customers demand perfection, precision engineering plays an integral role in meeting these expectations.

Another critical aspect where precision engineering proves vital is cost-effectiveness. By producing parts with extreme accuracy, there is minimal waste material or rework required during production. This results in significant cost savings for companies as they do not have to discard or re-manufacture faulty parts. Moreover, by utilizing computer-aided design (CAD) software for prototyping and simulation processes, any potential errors can be identified early on before beginning mass production. This reduces the risk of costly mistakes during manufacturing.

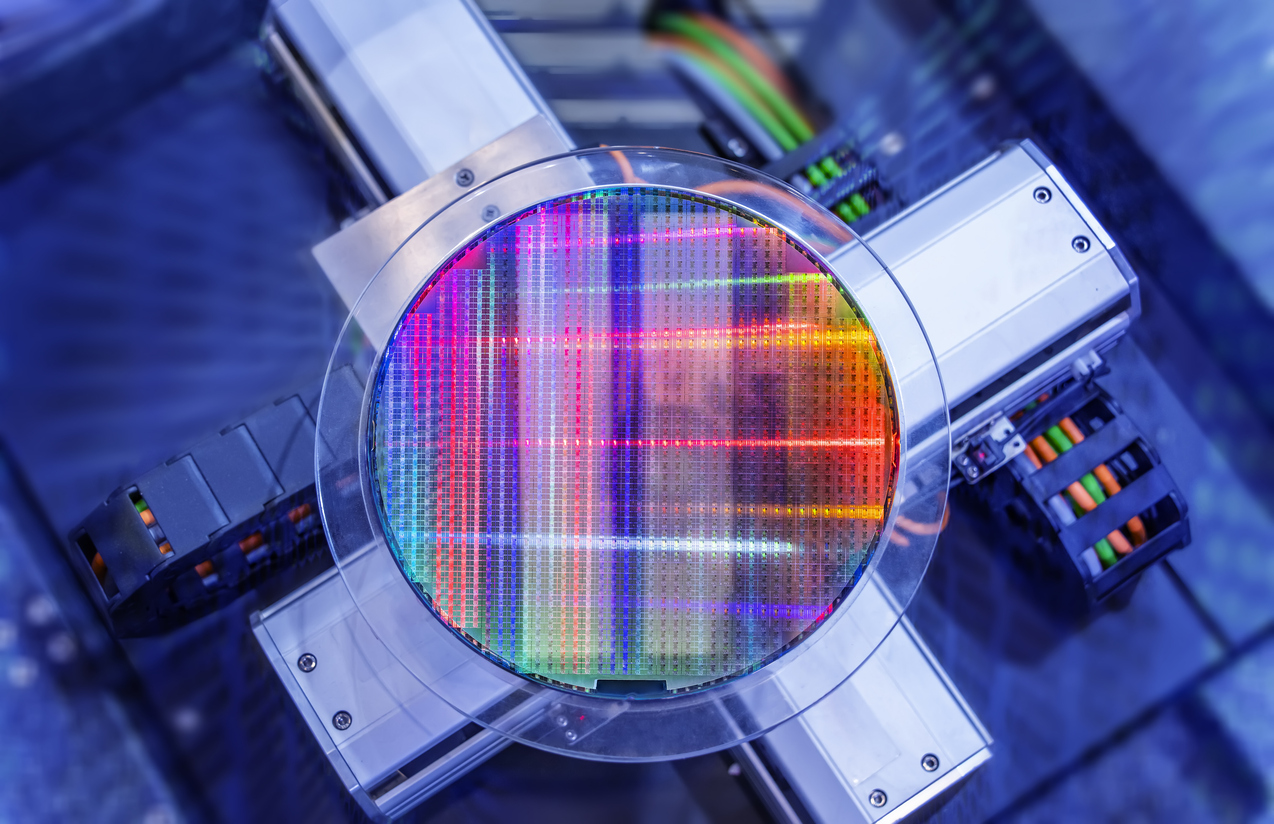

The use of advanced technologies such as Computer Numerical Control (CNC) machines has revolutionized the field of machining by enhancing speed and efficiency while maintaining high levels of precision. These machines can handle complex designs without compromising accuracy or quality, making them a valuable asset for modern industries looking to stay ahead of their competition.

Furthermore, precision engineering also plays a significant role in improving safety standards across different industries. By ensuring that each component meets strict tolerances and specifications during production, there is less risk of failure or malfunctioning equipment that could potentially harm workers or cause accidents.

In Nigeria, precision engineering has been a game-changer for the manufacturing sector. With the support of companies like Wigmore Trading, which provides cutting-edge CNC machines and other precision engineering tools, local industries can now produce high-quality products that meet international standards. This not only boosts their competitiveness but also contributes to the country’s economic growth.

Precision engineering is crucial in modern industries as it ensures high-quality, cost-effective, and safe production of various components and products. Its importance will continue to grow as technology advances and demands for perfection increase in today’s competitive market.

Economic Impact of Machining in Nigeria

The impact of machining in Nigeria has been significant, not only in the precision engineering industry but also in the overall economic growth of the country. Machining is a process that involves shaping and finishing raw materials into desired products using various tools and techniques. It plays a crucial role in the manufacturing sector, which contributes significantly to Nigeria’s GDP.

One of the primary benefits of machining is its contribution to job creation. The precision engineering industry relies heavily on skilled machinists who are trained to operate and maintain advanced machinery. With the growth of this sector, there has been an increase in employment opportunities for Nigerians, particularly those with technical skills. This has helped to reduce unemployment rates and improve the standard of living for many individuals.

Moreover, machining has also led to an increase in local production and reduced import dependence. Previously, Nigeria relied heavily on imported goods for its industrial needs due to inadequate domestic manufacturing capabilities. However, with advancements in machining technology and availability of locally produced raw materials, more industries can now produce their own parts and components without relying on foreign imports. This not only saves costs but also strengthens the local economy by keeping money within the country.

The use of precision engineering services such as CNC (Computer Numerical Control) machining has greatly improved productivity and efficiency in Nigerian industries. CNC machines are computer-controlled systems that can accurately produce complex designs with high levels of precision at a faster rate than traditional methods. This has enabled Nigerian manufacturers to compete globally by offering quality products at competitive prices.

In addition, increased investment in machining technology has led to a diversification of industries beyond traditional sectors like oil and gas. Machining is now used extensively across various industries such as automotive, aerospace, medical equipment manufacturing, agriculture machinery production, among others. This diversification helps create a more stable economy that is less dependent on one particular sector.

However, like any other developing nation’s economy, Nigeria’s precision engineering sector still faces some challenges. These include inadequate infrastructure, limited access to finance, and a shortage of skilled labor. To fully harness the potential of machining in Nigeria, there is a need for continued investment in infrastructure development and technical education.

The economic impact of machining in Nigeria cannot be overstated. It has contributed significantly to job creation, local production, efficiency, and diversification of industries. With continued investments and supportive government policies, the future looks promising for precision engineering in Nigeria with Wigmore Trading at the forefront driving this growth.

Challenges and Opportunities for Machining in Nigeria

Challenges and Opportunities for Machining in Nigeria:

Nigeria is a country with great potential for growth in the precision engineering industry. As one of the largest economies in Africa, it offers a vast market for machining services. However, like any other developing nation, Nigeria faces its fair share of challenges when it comes to the machining sector.

One of the major challenges faced by the machining industry in Nigeria is the lack of skilled labor. Despite having a large population, there is a shortage of qualified machinists and engineers who are well-versed in modern precision machining techniques. This leads to a limited pool of talent available to meet the growing demand for high-quality products and services.

In addition, inadequate infrastructure also poses a challenge for machining companies in Nigeria. The unreliable power supply and poor transportation networks make it difficult for businesses to operate efficiently. Frequent power outages not only disrupt production but also increase operational costs due to alternative sources of energy being used.

Another obstacle facing the Nigerian machining industry is access to capital. Many small and medium-sized enterprises (SMEs) struggle to secure funding from banks due to high-interest rates and strict lending criteria. This makes it challenging for these businesses to invest in advanced machinery and technologies that can improve their productivity and competitiveness.

Despite these challenges, there are also several opportunities available for machining companies looking to enter or expand their operations in Nigeria.

With an increasing demand for precision-engineered components across various industries such as oil & gas, automotive, construction, and agriculture, there is plenty of room for growth in the Nigerian market. The government has also been actively promoting foreign investment through initiatives such as tax incentives and easier business registration processes – making it an attractive destination for international investors.

Moreover, advancements in technology have allowed Nigerian businesses to adopt digital solutions that help streamline operations and reduce costs – providing opportunities for increased efficiency and productivity within the machining sector.

While there are certainly challenges that need to be addressed, the future of machining in Nigeria looks promising. With a growing economy, a favorable business environment, and access to advanced technologies, it is only a matter of time before Nigeria becomes a major player in the global precision engineering market. At Wigmore Trading, we are committed to supporting and empowering Nigerian businesses in their journey towards success in the machining industry.

Wigmore Trading: A Pioneer in Precision Engineering in Nigeria

Wigmore Trading is a leading company in the field of precision engineering in Nigeria. With over 20 years of experience, they have established themselves as pioneers in this rapidly growing industry. Their commitment to quality and innovation has made them a trusted name among their clients, both nationally and internationally.

Their journey began with a small workshop in Lagos, but today, Wigmore Trading has expanded its operations to multiple locations across the country. They specialize in providing high-quality machining solutions for various industries such as automotive, aerospace, oil and gas, and many others. Their state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to produce precise and complex components with utmost accuracy.

One of the key factors that set Wigmore Trading apart from its competitors is their team of highly skilled engineers and technicians. They possess extensive knowledge and expertise in precision engineering techniques such as CNC machining, milling, turning, drilling, grinding, and more. This enables them to handle even the most challenging projects with ease and deliver superior results within tight deadlines.

In addition to their technical capabilities, Wigmore Trading also places great emphasis on research and development. They continuously strive to enhance their processes through innovative ideas and advanced techniques to meet the ever-changing demands of the market. This dedication towards advancement has earned them recognition as one of the most forward-thinking companies in Nigeria’s precision engineering sector.

Moreover, Wigmore Trading adheres strictly to international quality standards such as ISO 9001:2015 certification. This demonstrates their commitment towards maintaining consistency in delivering top-notch products that meet or exceed customer expectations. They also prioritize safety protocols at all levels of production to ensure a safe working environment for their employees while delivering reliable products for their clients.

As an organization that values sustainable growth, Wigmore Trading incorporates eco-friendly practices into its operations wherever possible. They understand the importance of preserving our planet for future generations and actively take steps towards reducing waste generation during production, using sustainable resources, and implementing energy-efficient measures.

Wigmore Trading has established itself as a pioneer in precision engineering in Nigeria through its unwavering dedication towards quality, innovation, and sustainability. With the continuous growth of the manufacturing sector in Nigeria, it is evident that companies like Wigmore Trading will play a vital role in shaping the future of precision engineering in the country.

Innovations and Technological Advancements in the Field of Machining

Innovations and technological advancements in the field of machining have greatly transformed the landscape of precision engineering. With the rapid pace of technological development, new tools and techniques are constantly being introduced to make machining processes more efficient, precise, and cost-effective.

One of the most significant innovations in machining is computer numerical control (CNC) technology. This technology utilizes computer programs to control machine tools, allowing for greater accuracy and repeatability in machining operations. CNC machines can also run continuously without manual intervention, increasing productivity and reducing human error.

Another game-changing innovation is additive manufacturing or 3D printing. This process involves building a three-dimensional object by adding layers of material on top of each other based on a digital design. Additive manufacturing has revolutionized prototyping and small-scale production in precision engineering as it allows for complex shapes to be created with high accuracy.

The emergence of advanced materials such as composites and superalloys has also pushed the boundaries of what is possible in machining. These materials offer superior strength-to-weight ratios, making them ideal for aerospace, automotive, and medical applications. However, they also present unique challenges for traditional machining methods due to their toughness and resistance to heat.

To address these challenges, innovative cutting tools have been developed using advanced coatings such as diamond-like carbon (DLC) or cubic boron nitride (CBN). These coatings significantly increase tool life while maintaining sharpness during high-speed cutting operations.

Automation has also made its way into the world of precision engineering through robotic solutions for handling workpieces and performing repetitive tasks like deburring or polishing. This not only reduces labor costs but also improves consistency in quality since robots do not tire or make mistakes like humans.

Furthermore, Internet-of-Things (IoT) technologies have enabled real-time monitoring of machine performance through sensors installed on machines. This data can be analyzed to predict maintenance needs and optimize processes for maximum efficiency.

With the rise of Industry 4.0, the integration of these technologies into smart factories is becoming a reality, with machines communicating and working together seamlessly. This has led to the development of cyber-physical systems that enable self-monitoring, self-optimization, and autonomous decision-making.

Innovations and technological advancements have not only improved the precision and efficiency of machining processes but have also opened up new possibilities for complex designs and materials. As Nigeria’s manufacturing sector continues to grow, it is crucial for companies like Wigmore Trading to stay updated on these advancements to remain competitive in the global market.

Future Prospects for Machining in Nigeria with Wigmore Trading

The future prospects for machining in Nigeria with Wigmore Trading are bright and full of potential. As the economy of the country continues to grow and diversify, there is a high demand for precision engineering services, making machining an essential component of various industries.

One of the key factors driving the future growth of machining in Nigeria is the government’s focus on developing local manufacturing capabilities. With initiatives such as the “Made-in-Nigeria” policy, aimed at reducing imports and promoting locally made products, there is a significant push towards self-sufficiency and industrialization. This presents a great opportunity for companies like Wigmore Trading that offer quality machining services to meet the increasing demand for precision-engineered components.

Moreover, Nigeria’s strategic location within Africa makes it an ideal hub for trade and commerce. This has led to an influx of international businesses setting up operations in the country, further increasing the need for precision engineering services. As these companies require specialized parts and components tailored to their specific needs, they turn to reliable partners like Wigmore Trading for their machining requirements.

Another factor contributing to the bright future prospects for machining in Nigeria is advancements in technology. With rapid developments in CNC machinery and other cutting-edge tools used in precision engineering, Nigerian manufacturers can now produce high-quality products that meet international standards. This has not only increased efficiency but also opened doors for exporting locally manufactured goods to other countries.

Furthermore, Wigmore Trading’s commitment to investing in modern equipment and continuous training programs ensures that they stay ahead of industry trends and maintain their position as leaders in providing precision engineering solutions.

With a growing economy, favorable government policies, increased foreign investment opportunities along with technological advancements – all pointing towards a bright future – it is safe to say that there are immense opportunities available for wigmore trading company operating within this sector. In addition to this, their dedication towards staying updated with latest industry trends through investments into modern equipment show us just how committed they are towards providing the highest quality precision engineering services to their customers in Nigeria and beyond. As we look to the future, it is clear that machining with Wigmore Trading will continue to play a vital role in driving industrial growth and development in Nigeria.

Conclusion: Why Precision Engineering is Crucial for the Future of Manufacturing

Conclusion: Why Precision Engineering is Crucial for the Future of Manufacturing

Precision engineering has always played a crucial role in the manufacturing industry, and its importance is only increasing as we move towards an era of advanced technology and automation. In this blog post, we have explored the future of precision engineering in Nigeria with Wigmore Trading and how it is shaping the landscape of machining in the country. As we conclude our discussion, it is important to highlight why precision engineering is crucial for the future of manufacturing not just in Nigeria but globally.

Firstly, precision engineering plays a pivotal role in ensuring high-quality products. With advancements in technology, customers now have higher expectations when it comes to product quality. They want products that are precise, durable, and efficient. This requires manufacturers to produce components and parts with extremely tight tolerances and accuracy levels. Without precision engineering techniques such as CNC machining, this level of accuracy would be nearly impossible to achieve consistently.

Moreover, precision engineering also plays a significant role in reducing costs for manufacturers. By achieving tight tolerances and minimizing errors through techniques like Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), manufacturers can save on material wastage and rework costs. This not only leads to cost savings but also contributes to sustainable production practices by reducing waste.

Furthermore, precision engineering enables design flexibility which is essential for innovation in manufacturing. With traditional methods of manufacturing, there were limitations on what could be produced based on the available tools and equipment. However, with precision engineering techniques like 3D printing or laser cutting, complex designs can be produced efficiently without compromising on accuracy or quality.

Additionally, as mentioned earlier, automation is becoming increasingly prevalent in manufacturing processes. Precision engineering plays a critical role here as well by ensuring that machines are calibrated accurately to perform tasks with minimal human intervention. This improves efficiency while also reducing the risk of errors caused by human factors.

Precision engineering will continue to be crucial for the future of manufacturing. With its ability to produce high-quality products, reduce costs, enable design flexibility, and support automation, it is evident that precision engineering will play a significant role in shaping the manufacturing landscape not just in Nigeria but globally. Companies like Wigmore Trading are at the forefront of this revolution, and with their expertise and technological advancements, Nigeria’s machining industry is set to reach new heights.

Comments are closed.