The Journey from Mine to Market: How Wigmore Trading Sources and Delivers Zircon Sand

The Journey from Mine to Market: How Wigmore Trading Sources and Delivers Zircon Sand

Are you curious about the intricate journey that brings a rare and valuable mineral from deep within the earth to your doorstep? Look no further! Today, we’re taking you on an exhilarating adventure as we unveil the fascinating process behind sourcing and delivering zircon sand. Join us on this captivating exploration of Wigmore Trading’s remarkable efforts in bringing this exquisite material from mine to market. Get ready to be amazed by the meticulous steps involved in unearthing, refining, and transporting zircon sand – a journey filled with awe-inspiring tales of determination and innovation. Don’t miss out on this thrilling expedition into the heart of Wigmore Trading’s fascinating world!

Introduction to Wigmore Trading and Zircon Sand

Introduction to Wigmore Trading and Zircon Sand

Wigmore Trading is a global trading company that specializes in sourcing and delivering high-quality zircon sand. With over 30 years of experience in the mining industry, Wigmore Trading has established itself as a reliable and trusted supplier of zircon sand to various industries around the world.

Zircon sand, also known as zirconium silicate (ZrSiO4), is a naturally occurring mineral that is found in beach sands and some inland deposits. It is used in a wide range of applications such as ceramics, refractory materials, foundry molds, and jewelry making. Due to its unique properties, zircon sand has become an essential raw material for many industries.

In this article, we will take you on a journey from mine to market – exploring how Wigmore Trading sources and delivers zircon sand to meet the demands of different industries.

The Mining Process

The journey of zircon sand begins with the mining process. Zircon-containing minerals are typically found in heavy mineral sands deposits, which are formed by natural processes such as erosion and weathering. These deposits are primarily located along coastlines or in inland areas near ancient shorelines.

Once identified, these deposits are extracted using various methods such as dredging or dry mining techniques. Dredging involves extracting the mineral-rich sands from the ocean floor using large floating dredges.

What is Zircon Sand and its uses?

Zircon sand, also known as zirconium silicate, is a naturally occurring mineral that is found in beach sands and other sediments. It is typically extracted from heavy mineral deposits using dredging or dry mining techniques. Zircon sand has a unique combination of properties that make it valuable in various industries, including ceramics, refractories, foundries, and nuclear power.

One of the most notable characteristics of zircon sand is its high melting point (over 2,000°C), which makes it ideal for use in high-temperature applications. This property allows zircon sand to withstand extreme heat without melting or deforming, making it an essential component in the production of refractory materials such as furnace linings and crucibles.

In addition to its high melting point, zircon sand is also chemically inert and highly resistant to corrosion and abrasion. This makes it a popular choice for use in ceramic glazes and coatings as well as foundry molds for casting metals. Its ability to create smooth surfaces with excellent detail reproduction also makes it suitable for use in precision casting processes.

Moreover, zircon sand has excellent thermal shock resistance, meaning it can withstand sudden changes in temperature without cracking or breaking. This property makes it an essential component in the manufacture of certain types of ceramic tiles and sanitaryware that are exposed to frequent thermal cycling.

The Importance of Sourcing from Trusted Miners

In today’s global market, the sourcing of raw materials is a critical aspect of any business. This is especially true for industries such as construction and manufacturing, where quality and consistency are crucial for producing high-quality products. One such material that plays a significant role in these industries is zircon sand.

Zircon sand is a valuable mineral used in various applications, including ceramics, refractories, and foundry molds. However, not all zircon sands are created equal. The quality and purity of zircon sand vary depending on its source and the mining methods used to extract it. This is why Wigmore Trading takes great care in sourcing this precious material from trusted miners.

Sourcing from trusted miners means obtaining zircon sand from reputable mining companies that adhere to strict ethical and environmental standards. These companies follow responsible mining practices that prioritize worker safety, minimize environmental impact, and promote sustainable development.

One of the main reasons why sourcing from trusted miners is essential is to ensure product quality. Zircon sand obtained from reputable sources undergoes thorough testing to meet international standards for chemical composition, particle size distribution, and other specifications necessary for different industrial applications. This ensures that our clients receive consistent high-quality products every time they order from us.

Moreover, by sourcing exclusively from trusted miners, we can guarantee the traceability of our zircon sand. We know exactly where our raw materials come from – whether it’s sourced locally or internationally – which allows us to maintain transparency throughout the supply chain.

The Process of Exporting Zircon Sand and Zirconium

The export process for zircon sand and zirconium involves several steps to ensure a smooth and efficient delivery from the mine to the market. At Wigmore Trading, we pride ourselves on our extensive experience and knowledge in navigating this process to provide quality zircon products to our clients.

1. Mining and Processing:

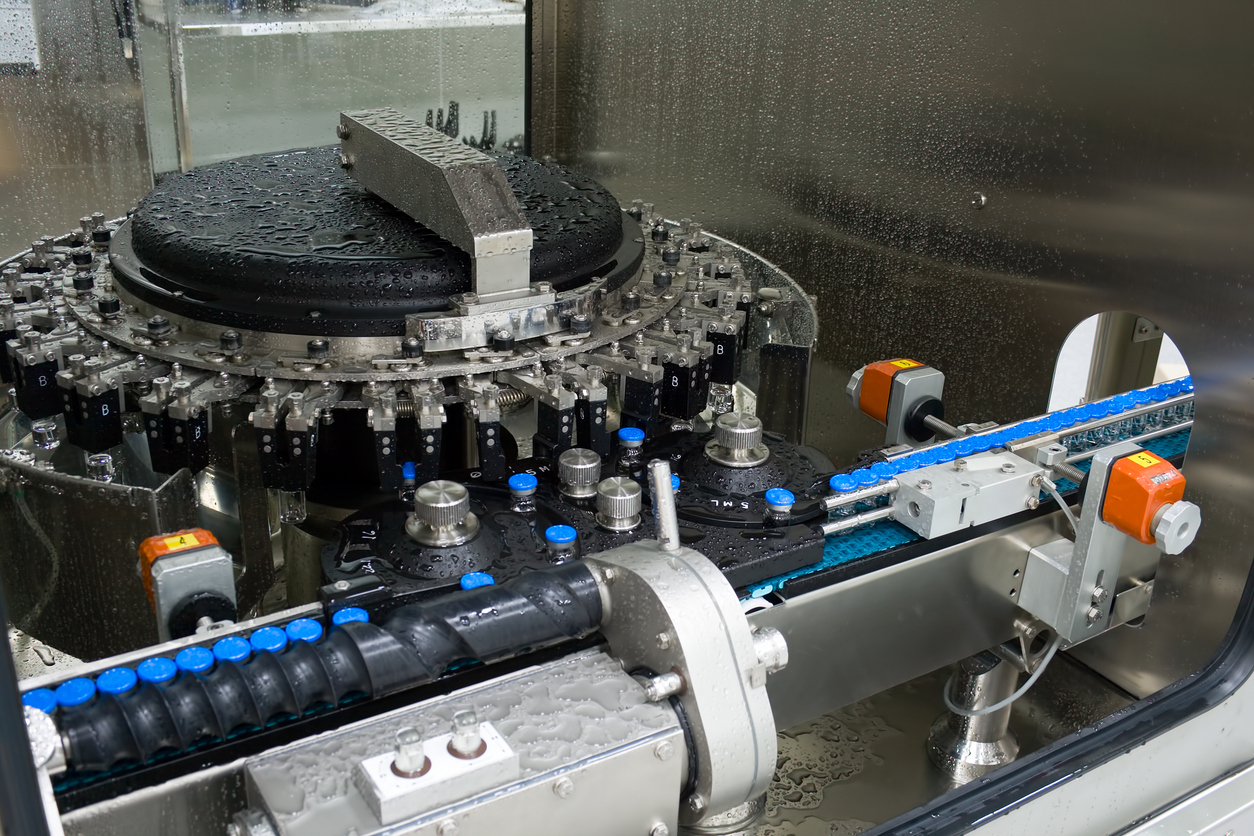

The first step in exporting zircon sand is mining it from its natural source. Zircon sand is primarily extracted through open-pit mining, which involves removing layers of soil, sand, and clay using heavy machinery. The ore is then transported to a processing plant where it undergoes several stages of crushing, grinding, and separating to obtain pure zircon sand.

2. Quality Control:

At Wigmore Trading, we understand the importance of quality control in the export process. As such, we have strict measures in place to ensure that only high-quality zircon sand is sourced for our clients. This includes conducting regular sampling and testing throughout the mining and processing stages to check for impurities or variations in product specifications.

3. Packaging:

Once the zircon sand has been processed and deemed suitable for export, it is then packed into large containers or bags based on client requirements. We take great care in ensuring that our packaging materials are durable enough to withstand long-distance transportation while also preventing any contamination or damage during transit.

Quality Control Measures at Wigmore Trading

At Wigmore Trading, we take great pride in ensuring that our zircon sand meets the highest quality standards before it reaches our customers. As a leading supplier of zircon sand, we understand the importance of delivering a consistent and reliable product to our clients. That’s why we have implemented stringent quality control measures at every stage of our sourcing and delivery process.

To begin with, we carefully select our mining partners based on their track record of producing high-quality zircon sand. Our team conducts regular site visits to inspect the mining operations and assess the quality of the extracted sand. We also work closely with these partners to ensure that they adhere to ethical and sustainable practices in their mining processes.

Once the raw zircon sand is obtained, it undergoes thorough testing at our in-house laboratory. Our team of experienced technicians performs various tests such as chemical composition analysis, particle size distribution, and moisture content analysis to determine the quality and purity of the sand. This helps us identify any impurities or inconsistencies that may affect its performance in industrial applications.

Furthermore, we have implemented a strict screening process for all incoming shipments of zircon sand. Our trained staff inspects each batch for physical defects or contaminants before accepting it into our inventory. If any issues are found during this inspection process, the shipment is rejected and returned to the supplier.

To maintain consistency in product quality, we also conduct regular checks throughout storage and handling procedures.

Partnerships with Buyers and Clients

Wigmore Trading is dedicated to sourcing and delivering high-quality zircon sand to our clients around the world. We understand that building strong relationships with buyers and clients is crucial in ensuring the success of our business. That’s why we have established partnerships with a wide range of buyers and clients, from small businesses to large corporations, in various industries.

One of the key factors that sets us apart from other zircon sand suppliers is our commitment to understanding the specific needs and requirements of each buyer or client we work with. We take the time to get to know their business, their processes, and their desired outcomes. This allows us to tailor our services and solutions accordingly, providing them with a seamless and hassle-free experience from start to finish.

Our partnerships begin even before a transaction takes place. Our team works closely with buyers and clients during the sourcing process, providing them with detailed information about the origin, quality, and availability of our zircon sand. This transparency helps build trust between us and our partners while also allowing them to make informed decisions about their purchase.

We also work closely with our partners throughout the delivery process. Our experienced logistics team ensures timely delivery of zircon sand using efficient transportation methods such as shipping by sea or air freight. We aim to provide a smooth delivery experience for all parties involved, keeping communication lines open throughout the process.

Furthermore, we believe that maintaining strong partnerships goes beyond just fulfilling orders. At Wigmore Trading, we value long-term relationships over short-term gains.

Sustainable Practices in Mining and Supply Chain Management

Sustainable practices in mining and supply chain management play a crucial role in the journey of zircon sand from mine to market. As a responsible supplier, Wigmore Trading understands the importance of minimizing environmental impact and promoting ethical practices throughout every step of the process.

Mining is an essential part of sourcing zircon sand, but it can also have significant negative impacts on the environment if not managed properly. That is why Wigmore Trading works closely with their mining partners to ensure that sustainable practices are implemented at all stages of the mining process.

One of the key sustainable practices in mining is responsible land use. This involves conducting thorough environmental assessments before starting any mining activities, ensuring that sensitive areas are avoided and proper reclamation plans are put in place. Wigmore Trading also encourages their partners to use modern technologies and equipment that minimize noise, dust, and other potential pollutants.

Another aspect of sustainable mining is water conservation. The extraction process for zircon sand requires large amounts of water, but Wigmore Trading’s mining partners utilize innovative techniques such as closed-loop systems to recycle water and reduce their overall consumption. This not only helps conserve this precious resource but also minimizes potential pollution from wastewater.

Furthermore, Wigmore Trading actively promotes ethical labor practices within their supply chain management processes. They work closely with their suppliers to ensure fair treatment and safe working conditions for all employees involved in the production of zircon sand. This includes regular audits to monitor compliance with labor laws and regulations.

Challenges and Solutions in the Zircon Sand Industry

Challenges and Solutions in the Zircon Sand Industry

The zircon sand industry faces several challenges throughout its supply chain, from mining to market. These challenges can range from natural occurrences such as weather conditions affecting mining operations, to more complex issues such as fluctuating demand and pricing. In this section, we will explore some of the key challenges faced by the zircon sand industry and how Wigmore Trading addresses them.

1. Mining Challenges

Mining is the first step in the journey of zircon sand from mine to market. However, it comes with its own set of challenges. One of the main challenges faced by mining companies is accessing high-quality ore deposits. As zircon sand is a heavy mineral, it tends to be found in areas with high concentrations of other heavy minerals such as titanium or monazite. This makes it difficult for mining companies to selectively extract zircon sand without also extracting unwanted minerals.

Furthermore, environmental concerns have led to stricter regulations for mining operations, making it challenging for companies to obtain necessary permits and licenses. To overcome these challenges, Wigmore Trading works closely with reputable mines that have proven track records of producing high-quality zircon sand while adhering to strict environmental standards.

2. Processing Challenges

After being mined, raw zircon sand needs to undergo processing before it can be used in various industries such as ceramics and refractories. The most common method of processing involves separating the different heavy minerals through gravity separation techniques like spiral concentrators or shaking tables.

Future of Zircon Sand Market and Wigmore Trading’s Role

The zircon sand market has experienced steady growth over the past few years and is expected to continue on this path in the future. Zircon sand, also known as zirconium silicate, is a naturally occurring mineral with various industrial applications. It is commonly used in the production of ceramics, refractories, and foundry casting molds. With an increasing demand for these products across industries such as construction, automotive, and aerospace, the zircon sand market is projected to reach a value of $1.8 billion by 2026.

In this constantly evolving market, Wigmore Trading has established itself as a prominent player in sourcing and delivering high-quality zircon sand to meet the needs of its customers. The company’s strategic partnerships with international mines and its efficient supply chain management have enabled it to stay at the forefront of this industry.

As technology continues to advance and industries become more environmentally conscious, there are some key trends that will shape the future of the zircon sand market.

1. Growing Demand for High-Purity Zircon Sand: As industries strive for greater efficiency and performance, there is an increasing demand for high-purity zircon sand that can withstand extreme temperatures and chemical reactions. This type of zircon sand is mainly used in refractory applications where it acts as a lining material for furnaces or kilns. Wigmore Trading recognizes this trend and works closely with its partners to ensure a consistent supply of premium-grade zircon sand.

–

Introduction to Zircon Sand:

Zircon sand is a natural mineral that is mostly made up of zirconium silicate. It is commonly found in beach sands and can also be mined from deposits in countries like Australia, South Africa, and India. Zircon sand has many industrial applications due to its unique properties such as high melting point, resistance to corrosion, and low thermal expansion.

Mining Process:

The journey of zircon sand begins with the mining process. The first step involves identifying potential sources of zircon sand through geological surveys and exploration activities. Once a suitable deposit is identified, the mining process begins.

There are two main methods used for extracting zircon sand – dredging and dry mining. Dredging involves using large floating dredges to suck up the sand from the seabed or riverbeds. This method is commonly used in coastal areas where zircon deposits are found on beaches or nearshore areas.

The other method, dry mining, involves using heavy earthmoving equipment to remove the overburden (layers of soil and rock) above the zircon deposit. The remaining layers containing zircon are then collected and processed further.

Processing and Refining:

After extraction, the raw material goes through several stages of processing to remove impurities and separate out pure zircon crystals. The first stage usually involves crushing and grinding the ore into smaller particles. Then various separation techniques such as gravity separation, magnetic separation, or electrostatic separation are used to separate out different minerals present in the ore

Comments are closed.