The Process and Benefits of Casting Iron in Nigeria: A Guide by Wigmore Trading

The Process and Benefits of Casting Iron in Nigeria: A Guide by Wigmore Trading

Have you ever wondered about the process of casting iron in Nigeria and the benefits that come with it? Look no further! In this comprehensive guide by Wigmore Trading, we will delve into the fascinating world of casting iron in Nigeria. From the intricate process involved to the numerous benefits it provides, this blog post is a must-read for anyone curious about this age-old craft. So sit back, relax, and let us take you on a journey through the art of casting iron in Nigeria.

Introduction to Casting Iron in Nigeria

Introduction to Casting Iron in Nigeria:

Casting iron is a process by which molten iron is poured into a mold and allowed to cool, forming a solid object. This technique has been used for centuries in various industries such as construction, manufacturing, and art. In Nigeria, casting iron has been an integral part of the traditional metalworking techniques of many indigenous communities.

Iron casting in Nigeria dates back to the ancient Nok culture around 500 BC. It was used primarily for creating tools and weapons for agricultural purposes. However, with advancements in technology and increased demand for industrial products, the process of casting iron has evolved and become more sophisticated.

Today, Nigeria boasts a flourishing foundry industry that produces high-quality cast iron products for both domestic and international markets. The country is known for its abundance of natural resources, including iron ore deposits that make it an ideal location for producing cast iron.

The Process of Casting Iron:

The process of casting iron involves several steps that require precision and expertise. Firstly, raw materials such as scrap metal or pig iron are melted in a furnace at extremely high temperatures (around 1300°C). This molten liquid is then poured into sand molds made from silica or clay.

After cooling down and solidifying inside the molds, the newly formed castings are removed from the sand molds using specialized equipment. These castings are then cleaned, inspected for any defects or imperfections, and finally finished with surface treatments like painting or polishing.

Benefits of Casting Iron:

One of the main advantages of casting iron is its strength and durability. Cast iron products can withstand heavy loads without breaking or deforming easily. This makes them suitable for use in various industries where sturdy materials are required.

Additionally, cast iron is highly resistant to corrosion due to its high carbon content. This property makes it ideal for outdoor applications where exposure to harsh weather conditions may cause other metals to deteriorate quickly.

Moreover, casting allows intricate and complex shapes to be formed with precision, making it a versatile method for creating a wide range of products. In Nigeria, cast iron is used for manufacturing cookware, water pipes, machinery parts, sculptures, and many other items.

Conclusion:

Casting iron has played a significant role in the development of Nigeria’s economy and has become an essential part of its industrial landscape. The process offers various benefits such as strength, durability, and versatility that make it a preferred choice for many applications. With advancements in technology and growing demand for high-quality products, the future of casting iron in Nigeria looks promising.

History of Iron Casting in Nigeria

The history of iron casting in Nigeria can be traced back to ancient times when the Nok people, who inhabited what is now known as Northern Nigeria, were skilled in the art of metalworking. They used iron to create tools and weapons for daily use and for trade with neighboring communities.

With the arrival of Europeans in the 15th century, traditional iron casting methods were gradually replaced by more modern techniques brought from Europe. The British colonial government also played a significant role in promoting industrialization and modernization in Nigeria, leading to an increase in iron production and casting.

During this period, large-scale foundries were established in major cities such as Lagos, Ibadan, and Kano. These foundries utilized advanced technology and machinery to produce a wide range of cast iron products for both local consumption and export. However, with the decline of colonial rule and the subsequent independence of Nigeria in 1960, many of these foundries were forced to shut down due to economic challenges.

In recent years, there has been a resurgence of interest in traditional iron casting methods among local artisans and craftsmen. This has been fueled by a growing demand for locally made cast iron products as well as efforts by organizations like Wigmore Trading to promote indigenous industries.

Today, there are various small-scale foundries scattered across different regions of Nigeria that specialize in producing high-quality cast iron products using traditional methods passed down through generations. These foundries source their raw materials from local mines and employ skilled artisans who have honed their craft over years of practice.

One notable example is the Ife Bronze Casting tradition practiced by the Yoruba people which dates back over 900 years ago. This technique involves creating intricate molds using locally sourced clay mixed with other organic materials such as grass or cow dung. The molten metal is then poured into these molds before being cooled down and carefully removed to reveal beautifully crafted objects such as sculptures, utensils, and decorative items.

The history of iron casting in Nigeria is a testament to the country’s rich cultural heritage and its ability to adapt and evolve with changing times. Today, traditional methods are being combined with modern technology to produce high-quality cast iron products that showcase the skill and creativity of Nigerian artisans.

The Process of Casting Iron with Wigmore Trading

The art of casting iron has been an integral part of human history for centuries. From ancient civilizations to modern industries, iron casting has played a crucial role in shaping various tools and objects that we use in our daily lives. In Nigeria, the process of casting iron is still prevalent and remains an essential technique for producing high-quality and durable products.

At Wigmore Trading, we take pride in our expertise when it comes to the process of casting iron. Our team is well-versed in the traditional methods of iron casting, as well as incorporating modern techniques to produce superior quality castings. Here’s a detailed breakdown of how we carry out the process:

1. Design and Pattern Making:

The first step in any successful cast iron project is designing the product and creating patterns for it. At Wigmore Trading, our experienced team works closely with clients to understand their specific requirements and create accurate design blueprints for their desired product.

2. Moulding:

Once the design is finalized, we move on to moulding – a critical stage in the casting process. The moulds are made from sand or clay mixture pressed tightly around the pattern created earlier. This creates an impression or negative cavity which will eventually be filled with molten metal.

3. Melting:

Next comes melting – where scrap iron or pig iron is melted down at extremely high temperatures (around 1200°C) using a furnace or crucible. At this stage, additives such as carbon are added to achieve desired properties like strength and hardness.

4.Casting:

Once the metal reaches its liquid form, it is poured into the prepared mould through a gating system that channels molten metal into different sections of the mould without causing turbulence or air bubbles.

5.Cooling and Shakeout:

After pouring, the metal begins to cool down almost instantly within minutes due to contact with cooler surfaces inside the mould. Once completely cooled down, which can take up to several hours depending on the size and complexity of the product, the mould is broken to retrieve the solidified cast iron.

6. Finishing:

The final stage involves removing any excess material from the casting and giving it a smooth finish. This can be done through grinding, sanding, or shot blasting to achieve desired surface texture and appearance.

As you can see, casting iron at Wigmore Trading is a meticulous process that requires expertise and precision every step of the way. Our team ensures that each product meets the highest standards of quality before being delivered to our clients.

By choosing Wigmore Trading for your casting needs, you can rest assured that you will receive top-notch products made with utmost care and attention. We take great pride in preserving this age-old technique while continuously improving our methods to meet modern industrial standards.

– Gathering Raw Materials

Gathering raw materials is the first step in the process of casting iron. In Nigeria, there are various sources for obtaining these materials, including scrap metal yards, local mines, and international suppliers.

The primary raw material used in iron casting is iron ore. Iron ore can be found in abundance in many parts of Nigeria, particularly in states such as Kogi, Enugu, and Anambra. This natural resource is essential for producing high-quality cast iron due to its high iron content. The process of mining involves extracting the ore from the ground and crushing it into small particles.

Apart from iron ore, other materials needed for casting include coke or coal and limestone. Coke or coal is used as a fuel source to melt the iron ore during the smelting process. Limestone acts as a fluxing agent that helps remove impurities from the molten metal and improves its quality. These materials are also readily available in Nigeria through local mines or imported from countries like South Africa or China.

In addition to these primary raw materials, other secondary elements are added to improve the properties of cast iron according to specific requirements. These elements include silicon, manganese, sulfur, and phosphorus. Silicon increases fluidity and strength while reducing brittleness; manganese helps prevent oxidation during melting; sulfur enhances machinability; and phosphorus improves fluidity but can make castings more prone to cracking if not controlled properly.

Scrap metal yards play a significant role in providing an alternative source of raw material for casting industries in Nigeria. Scrap metal includes discarded machinery parts or appliances made of cast iron that can be recycled for use in new products. It reduces costs because it eliminates the need to extract new resources and has minimal impact on the environment.

Once all necessary raw materials have been collected or purchased, they are then transported to foundries where they undergo various processes such as sorting, cleaning, melting, refining before being poured into molds to create cast iron products.

The process of gathering raw materials for casting iron in Nigeria is crucial and involves sourcing from various local and international suppliers. The use of alternative sources such as scrap metal yards not only reduces costs but also promotes sustainability by reducing the need for new resources. This initial step sets the foundation for producing high-quality cast iron products that are essential to many industries in Nigeria.

– Melting and Pouring the Iron

Melting and pouring are crucial steps in the process of casting iron. These steps involve heating the raw materials and transforming them into molten metal, which is then poured into molds to create the desired shape.

The first step in melting iron is to gather all the necessary raw materials such as pig iron, scrap metal, coke, limestone, and ferroalloys. These materials are then placed in a large furnace called a cupola or an electric arc furnace (EAF). The choice of furnace depends on factors such as cost, availability of resources, and scale of production.

In the cupola furnace, all the raw materials are loaded from the top and heated by burning coke at high temperatures. This process produces hot combustion gases that rise through the charge and heat it up. As these gases pass through the charge, they react with oxygen present in the iron oxide to produce carbon dioxide gas and liquid iron.

On the other hand, EAF uses electricity to melt scrap metal and other alloys in a refractory-lined vessel. An electric arc is formed between graphite electrodes that heat up and melt all the materials in their path.

Once melted, impurities such as slag float on top of molten iron due to their lower density. The slag is then removed using special tools called skimmers while tapping holes at regular intervals allow for controlled release of molten iron into ladles or molds.

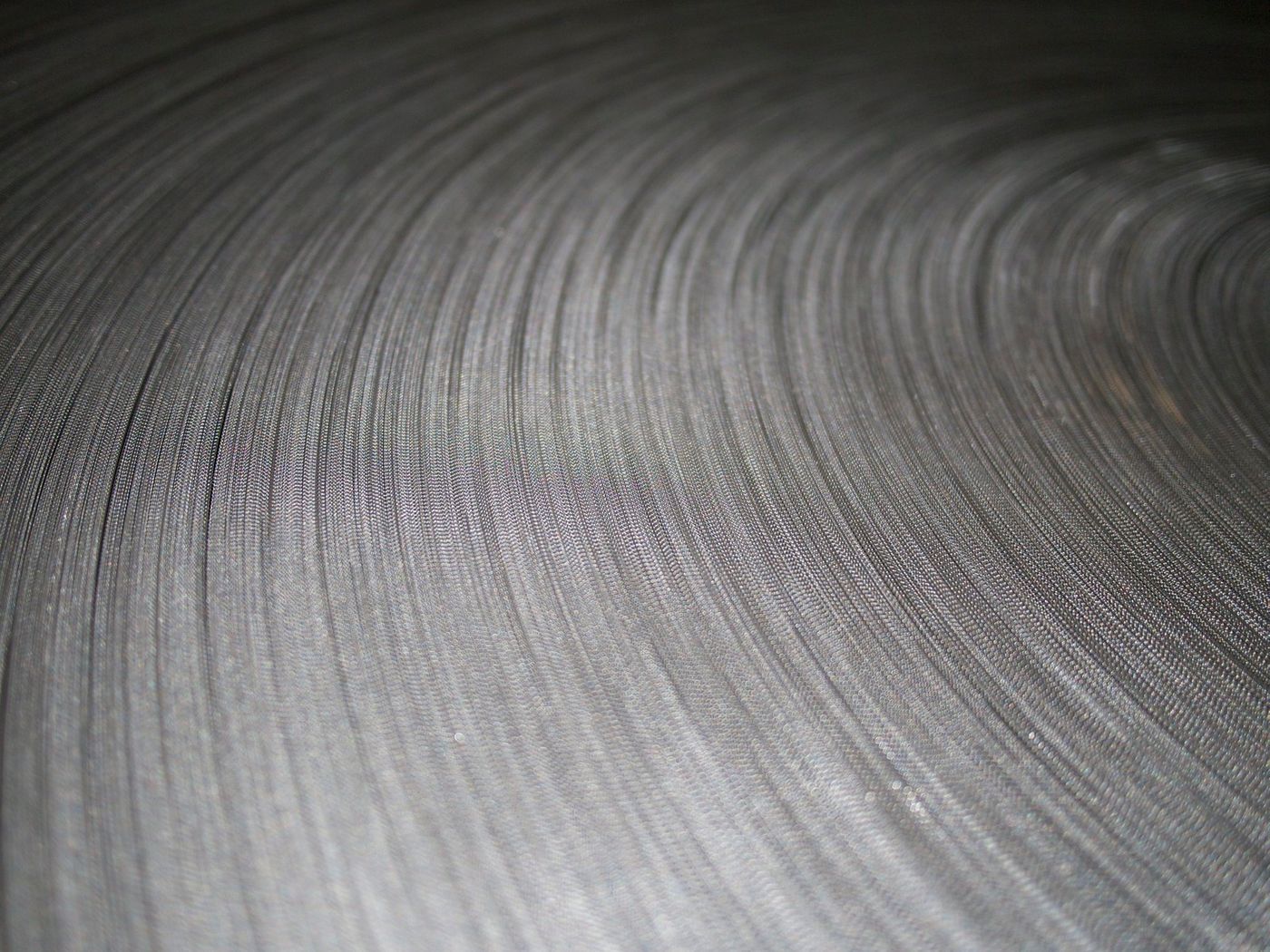

Pouring refers to transferring molten metal from one container to another for further processing. In casting iron, pouring involves filling molds with liquid iron using ladles or automatic pouring machines. Care must be taken during this process as any turbulence can lead to defects in castings such as porosity or uneven distribution of material.

One key advantage of casting iron using traditional methods like cupolas is that it allows for flexibility in production quantities. Smaller foundries can easily adjust their output by controlling how much material goes into each batch based on customer demand. EAF, on the other hand, is better suited for large-scale productions as it can melt larger quantities of iron at once.

Melting and pouring are critical stages in casting iron that require specialized knowledge and equipment. The use of modern technologies such as EAF has improved efficiency in the process, but traditional methods like cupola furnaces remain relevant in small-scale production due to their flexibility.

– Molding and Shaping the Iron

Molding and shaping iron is a crucial step in the process of casting iron. In this stage, the molten metal is poured into a mold to give it a desired shape and form. This process requires skill and precision as any errors or imperfections in the mold can result in defects in the final product.

The first step in molding is selecting the right type of sand for the mold. The sand used for molding should have good refractory properties, meaning it should be able to withstand high temperatures without melting or fusing together. In Nigeria, silica sand is commonly used for this purpose as it has excellent refractory properties.

Next, a pattern or template of the desired shape is placed into the sand and pressed down firmly to create an impression. This pattern can be made from wood, plastic, or metal depending on the complexity of the shape being molded.

Once the pattern is removed, two halves of a flask (a frame made of metal) are then placed around the impression created by the pattern. These halves are held together by pins and bolts to ensure that they do not move during pouring.

The next step involves creating channels known as runners and risers within the mold. Runners are channels through which molten metal flows into different parts of the mold while risers are used to allow air to escape during pouring.

After preparing all these elements, molten iron is then poured into one end of the runner until it fills up all parts of the mold. It takes skill and practice for workers to control how fast or slow they pour so that there are no air pockets formed inside which could weaken or damage its structural integrity.

Once filled, excess molten iron is allowed to drain out through gates at various points where excess material would accumulate during solidification. Once cooled down completely, molds are separated from their patterns leaving behind an exact replica which needs minimal finishing work before use.

One major benefit of molding and shaping iron is that it allows for mass production of complex shapes and designs. This has greatly helped in meeting the demand for iron products in Nigeria as it can be used to create a wide range of products such as machinery parts, tools, and household items.

Molding and shaping are essential steps in the process of casting iron. It requires skilled labor and specialized equipment to produce high-quality molds that result in strong and durable iron products. With its many benefits, it is no wonder that this method has been widely adopted by manufacturers in Nigeria.

– Finishing and Quality Control

Finishing and Quality Control:

After the iron has been poured into the mold, the final step in the casting process is finishing and quality control. This crucial stage ensures that the casted iron meets all specifications and standards, ensuring its overall quality.

The first step in finishing is removing any excess material or metal from the casting. This can be done through a variety of methods such as sandblasting, grinding, or using cutting tools. The goal is to smooth out any rough edges or imperfections on the surface of the casting.

Next, any gates or risers that were used to pour the molten iron into the mold are removed. These are typically made of sand and need to be broken off carefully to avoid damaging the casted iron.

Once all excess materials have been removed, it’s time for quality control. This involves inspecting each individual piece for any defects such as cracks, holes, or deformities. Any issues found during this process will need to be addressed before moving on to further finishing steps.

One important aspect of quality control in casting iron is checking for proper hardness levels. Iron should have a specific level of hardness depending on its intended use – too hard and it becomes brittle and prone to breaking; not hard enough and it may not be strong enough for its intended purpose.

Another key factor in quality control is checking dimensional accuracy. Each piece must meet precise measurements and tolerances in order for it to fit correctly when assembled with other parts.

To ensure consistency among multiple pieces being produced, samples are taken at regular intervals during production and tested against set standards. If there are deviations from these standards, adjustments can be made immediately to correct them before continuing with production.

In addition to physical inspections, non-destructive testing methods can also be used during quality control processes. Techniques such as X-rays or ultrasonic testing can reveal internal flaws that may not be visible externally.

Once all necessary inspections have been completed, the casted iron is ready for its final finishing touches such as painting, coating, or polishing. These steps not only improve the appearance of the final product but also provide additional protection against corrosion and wear.

Finishing and quality control are crucial steps in the casting process that ensure the production of high-quality, reliable casted iron products. Through careful attention to detail and adherence to standards and specifications, Wigmore Trading guarantees top-notch castings for all your industrial needs in Nigeria.

Advantages of Casting Iron in Nigeria with Wigmore Trading

Casting iron is a widely used method for creating strong and durable metal products. In Nigeria, this process has been made more accessible and efficient thanks to the services provided by Wigmore Trading. As a leading supplier of foundry and casting materials in the country, Wigmore Trading offers several advantages when it comes to using casting iron in Nigeria.

1. High Quality Materials: One of the biggest advantages of using casting iron with Wigmore Trading is access to high-quality materials. The company sources its materials from reliable manufacturers, ensuring that their clients receive top-notch products. This guarantees that the final product will be strong and long-lasting, making it a cost-effective option for businesses.

2. Customization Options: Another benefit of using casting iron with Wigmore Trading is their ability to customize products according to specific requirements. This allows businesses to have control over the design and functionality of their cast iron products, making them suitable for various applications. Whether it’s for industrial machinery or household items, Wigmore Trading can provide tailor-made solutions to meet different needs.

3. Reduced Production Time: With modern equipment and techniques, casting iron at Wigmore Trading is a quick process compared to traditional methods. This means that businesses can have their orders delivered within shorter lead times, allowing them to keep up with production demands and deadlines.

4. Cost-Effective Solution: Using casting iron with Wigmore Trading also proves to be a cost-effective solution in several ways. Firstly, as mentioned earlier, the high-quality materials used ensure that products have a longer lifespan compared to other options like plastic or wood. Additionally, customizing products eliminates unnecessary waste while reducing production time results in lower labor costs.

5.Quality Control Measures: Maintaining quality standards is crucial when it comes to manufacturing metal products, especially those used in critical applications like construction or transportation industries. With Wigmore Training’s experienced team and advanced testing equipment, you can trust that all castings produced meet the highest quality standards.

Using casting iron with Wigmore Trading provides numerous advantages for businesses in Nigeria. From high-quality materials and customization options to reduced production time and cost-effectiveness, it’s a reliable solution for various industries. Additionally, the company’s commitment to quality control ensures that clients receive products that meet their expectations every time.

Common Uses of Cast Iron Products in Nigeria

Cast iron has been used for centuries in a variety of industries and applications, and Nigeria is no exception. This durable and versatile material has a wide range of common uses across the country, from household goods to industrial machinery. In this section, we will explore the most common uses of cast iron products in Nigeria.

1. Cookware

One of the most well-known uses of cast iron products in Nigeria is for cooking. Cast iron cookware, such as pots and pans, have been used for generations in Nigerian households. The high heat retention and even heat distribution properties make it perfect for traditional cooking methods like stewing, frying, and baking. Additionally, cast iron cookware is known for its durability and can last for decades with proper care.

2. Construction

Another prevalent use of cast iron products in Nigeria is in the construction industry. Cast iron pipes are commonly used for plumbing systems due to their strength and resistance to corrosion. They are also used as drainage pipes in buildings as they can withstand heavy loads without collapsing. Additionally, cast iron is often used to make manhole covers due to its durability and weight-bearing capacity.

3. Automotive Industry

The automotive industry is another significant consumer of cast iron products in Nigeria. Many car parts such as engine blocks, brake drums, and cylinder heads are made from cast iron due to its high strength-to-weight ratio and ability to withstand extreme temperatures.

4. Agricultural Machinery

In rural areas where agriculture is a primary source of livelihood, many farm implements are made from cast iron. These include plows, hoes, sickles, and other tools that require strength and durability to handle tough farming tasks.

5 . Household Goods

Apart from cookware mentioned earlier, there are several other household items made from cast iron that are commonly found in Nigerian homes such as door handles, hinges, furniture frames,and decorative pieces like wall sconces or candle holders.

6 . Industrial Machinery

Many industries in Nigeria rely on cast iron products for their machinery and equipment. The strength, durability, and heat resistance of cast iron make it a suitable material for heavy-duty machines used in manufacturing, mining, and construction.

Cast iron products have a wide range of uses in Nigeria due to their numerous beneficial properties. From everyday household items to heavy industrial machinery, cast iron plays a vital role in various sectors across the country. At Wigmore Trading, we take pride in providing high-quality cast iron products that meet the diverse needs of our customers.

Challenges and Solutions in the Iron Casting Industry in Nigeria

The iron casting industry in Nigeria faces numerous challenges that have hindered its growth and development. These challenges range from technological limitations, inadequate infrastructure, and lack of skilled labor to environmental concerns and economic factors. In this section, we will discuss the major challenges faced by the iron casting industry in Nigeria and the potential solutions to overcome them.

One of the biggest challenges facing the iron casting industry in Nigeria is the limited access to modern technology. Most foundries in the country still use traditional methods of melting iron, which are not only time-consuming but also result in poor quality castings. This makes it difficult for Nigerian foundries to compete with those using advanced technology in other countries. To address this challenge, there is a need for investment in modern equipment and training of workers on how to operate them effectively.

Furthermore, inadequate infrastructure such as power supply and transportation also poses a significant challenge for the iron casting industry in Nigeria. Frequent power outages lead to disruptions in production processes, resulting in delays and increased costs. Additionally, poor roads make it challenging to transport raw materials and finished products from one location to another efficiently. The government needs to invest more resources into improving infrastructure, particularly in industrial areas where most foundries are located.

Another major challenge facing the iron casting industry is the shortage of skilled labor. The process of casting iron requires specialized skills and knowledge that can only be acquired through proper training and experience. Unfortunately, there is a lack of technical schools or vocational training centers that offer courses specifically tailored towards equipping individuals with these skills. As a result, many foundries struggle with finding qualified workers who can operate machinery effectively and produce high-quality castings.

Environmental concerns are also a significant challenge for the iron casting industry in Nigeria. Traditional methods used for melting iron release harmful emissions into the atmosphere which contribute significantly to air pollution. These emissions not only pose health risks but also harm the environment by contributing to climate change. To combat this challenge, there is a need for foundries to adopt more environmentally friendly methods of melting iron such as electric arc furnaces or induction furnaces.

The iron casting industry in Nigeria faces several challenges that need to be addressed for its growth and development. These include investing in modern technology, improving infrastructure, increasing access to skilled labor, and adopting environmentally friendly practices. With proper solutions in place, the Nigerian iron casting industry has the potential to thrive and contribute significantly to the country’s economy.

Conclusion:

Conclusion:

Casting iron has been a traditional method of manufacturing in Nigeria for centuries, and it continues to be an important industry in the country. From household items to industrial equipment, cast iron products can be found in various forms all over the country.

Through this guide, we have explored the process and benefits of casting iron in Nigeria. We have learned about the materials used, the steps involved, and the different types of cast iron products that are produced.

One of the main advantages of casting iron is its strength and durability. It is able to withstand high temperatures and heavy loads, making it ideal for use in machinery and infrastructure projects. Cast iron items also have a long lifespan, reducing the need for frequent replacements.

Moreover, casting iron is a cost-effective production method. The raw materials used are abundant in Nigeria, making them easily accessible and affordable. This allows for local manufacturers to produce high-quality cast iron products at competitive prices.

Another benefit of casting iron is its versatility. It can be molded into various shapes and sizes depending on the desired product specifications. This flexibility makes it suitable for a wide range of applications such as cookware, pipes, decorative items, and more.

Furthermore, casting iron has environmental benefits as well. The production process uses scrap metal which reduces waste while also conserving natural resources. Additionally, cast iron products can easily be recycled once they reach their end-of-life stage.

Casting iron is a vital part of Nigeria’s economy and heritage. Its strong yet versatile nature makes it indispensable in many industries across the country. With advancements in technology and techniques, Nigerian manufacturers continue to produce high-quality cast iron products that meet both local and international standards.

At Wigmore Trading Ltd., we take pride in being one of Nigeria’s leading suppliers of quality cast iron products through our partnership with reputable foundries within the country. We hope that this guide has provided valuable insights into the world of casting iron in Nigeria and has sparked an interest in this ancient yet evolving method of production.

Comments are closed.