Transforming the Oil and Gas Industry with Wigmore Trading’s Robotic Blasting Services

Transforming the Oil and Gas Industry with Wigmore Trading’s Robotic Blasting Services

The world is constantly evolving, and the oil and gas industry is no exception. With the increasing demand for energy, companies are continuously looking for ways to optimize their operations while minimizing costs. And in this quest for efficiency, Wigmore Trading has emerged as a game-changer with its innovative robotic blasting services that promise to revolutionize how we extract oil and gas from the ground. In this blog post, we will explore how Wigmore Trading’s technology is transforming the industry and what benefits it brings to both businesses and consumers alike. So buckle up as we take you on a journey into the future of oil and gas extraction!

Introduction to Wigmore Trading and Robotic Blasting Services

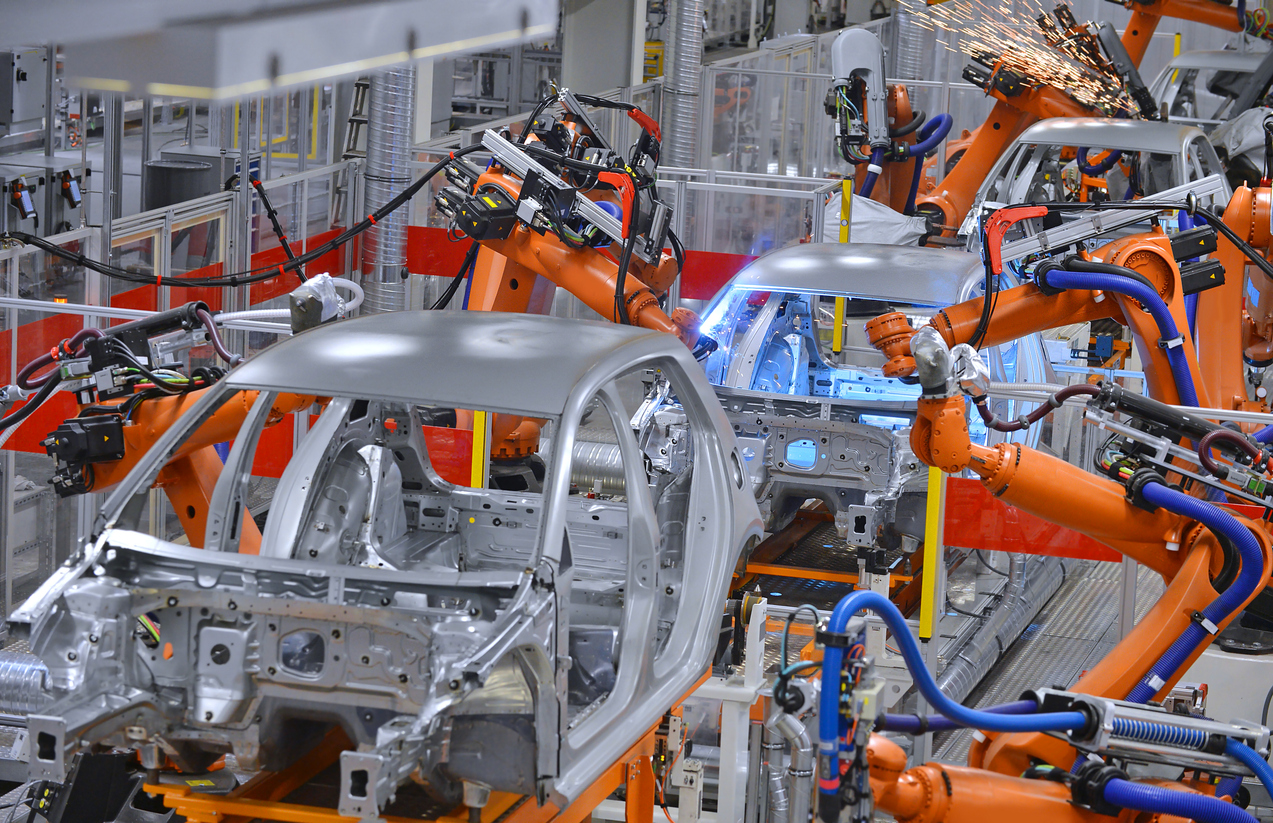

Wigmore Trading’s robotic blasting services are revolutionizing the oil and gas industry. Our services are designed to improve safety, efficiency, and productivity in the upstream oil and gas sector. We offer a complete suite of robotic blasting services, including:

-Surface Preparation: Our surface preparation services are designed to clean and prepare surfaces for further treatment. We use high-pressure water jets and abrasive media to remove contaminants, scale, rust, and other build-up from surfaces.

-Coating Removal: Our coating removal services are designed to remove paint, coatings, or other materials from surfaces. We use high-pressure water jets and abrasive media to safely remove coatings without damaging the underlying surface.

-Pipeline Cleaning: Our pipeline cleaning services are designed to clean pipelines of all sizes. We use high-pressure water jets and abrasive media to remove corrosion, scale, debris, and other build-up from pipelines.

-Tank Cleaning: Our tank cleaning services are designed to clean storage tanks of all sizes. We use high-pressure water jets and abrasive media to remove contaminants, sludge, and other build-up from tanks.

Our robotic blasting services are available 24/7/365. We have a team of highly trained and experienced operators who can safely and effectively operate our equipment. Contact us today to learn more about our robotic blasting services or to request a quote!

Benefits of Robotic Blasting for the Oil and Gas Industry

Robotic blasting is a transformative technology for the oil and gas industry, providing significant benefits in terms of safety, efficiency, and cost-effectiveness.

In terms of safety, robotic blasting eliminates the need for workers to enter dangerous environments, such as tanks and pipelines. This reduces the risk of accidents and injuries, as well as exposure to harmful chemicals and fumes.

In terms of efficiency, robotic blasting is much faster and more accurate than traditional methods. This means that projects can be completed more quickly, with less waste and less rework. Additionally, robotic blasting can be used to clean hard-to-reach areas that would otherwise be inaccessible.

Finally, robotic blasting is highly cost-effective. The upfront investment is typically offset by the savings in labor costs, material costs, and project timelines. In addition, robotic blasting systems can be used for multiple projects over their lifetime, further reducing costs.

How Robotic Blasting Works in Nigeria

The oil and gas industry in Nigeria is under pressure to improve efficiency and reduce costs. Wigmore Trading’s robotic blasting services are transforming the industry by providing a cost-effective solution that improves productivity and safety.

Robotic blasting is a process that uses robots to clean surfaces. The robots are equipped with high-pressure air nozzles that blast away dirt, grime, and other contaminants. This process is safe, efficient, and effective, and it helps oil and gas companies save money on labor and equipment costs.

Wigmore Trading’s robotic blasting services have already helped several oil and gas companies in Nigeria improve their operations. One company reported a 70% reduction in downtime, while another saw a 90% improvement in safety compliance.

If you’re looking for a way to improve your oil and gas company’s operations, contact Wigmore Trading today to learn more about our robotic blasting services.

Case Study: Success Stories of Nigerian Oil and Gas Companies Utilizing Wigmore Trading’s Robotic Blasting Services

Wigmore Trading’s robotic blasting services are transforming the oil and gas industry, with Nigerian oil and gas companies leading the way.

Nigerian oil and gas companies have long been struggling to find ways to improve their operations and increase production. With the high cost of traditional methods, many companies have turned to Wigmore Trading’s robotic blasting services as a means of reducing costs and increasing efficiency.

So far, the results have been impressive, with several Nigerian oil and gas companies reporting significant increases in production after implementing Wigmore Trading’s services. In addition, the use of robots has allowed for a safer working environment for employees, as they are not exposed to the harmful chemicals used in traditional blasting methods.

With its proven track record of success in Nigeria, Wigmore Trading is poised to transform the oil and gas industry on a global scale. As more and more companies adopt its robotic blasting services, we will see a new era of efficiency and safety in the industry.

Comparisons between Conventional Blasting and Robotic Blasting in the Oil and Gas Industry

There are many benefits to using robotic blasting services in the oil and gas industry. One of the most significant advantages is the increased accuracy and precision that can be achieved with this technology. When compared to conventional blasting methods, robotic blasting can provide a much higher level of control over the placement of explosives. This can lead to improved safety for workers and better results for the company. In addition, robotic blasting is much more efficient than traditional methods, which can save time and money.

Challenges Associated with Implementing Robotic Blasting Technology

There are many challenges associated with implementing robotic blasting technology. One challenge is that the robots need to be able to operate in a variety of environments, including offshore and onshore oil and gas production facilities. Another challenge is that the robots need to be able to handle a variety of material types, including steel, concrete, and rocks. Yet another challenge is that the robots need to be able to blast accurately and at high speeds. Finally, the robots must be able to withstand the harsh conditions found in many oil and gas production facilities.

LEAVE A COMMENT

You must be logged in to post a comment.