Unleashing the Power of Carboxy Methyl Cellulose: A Game-Changer in Nigeria and Africa

Unleashing the Power of Carboxy Methyl Cellulose: A Game-Changer in Nigeria and Africa

Are you ready to witness the game-changer that will revolutionize industries across Nigeria and Africa? Look no further than carboxy methyl cellulose (CMC), a powerful innovation with limitless possibilities. From enhancing food products to improving pharmaceuticals, CMC is set to unleash its potential and transform the way we live, work, and create in this promising region. Join us on an exciting journey as we dive into the world of CMC and explore how it has become a catalyst for progress, opening doors to endless opportunities. Buckle up and get ready for a thrilling ride through the power of carboxy methyl cellulose!

Introduction to Carboxy Methyl Cellulose (CMC)

Introduction to Carboxy Methyl Cellulose (CMC)

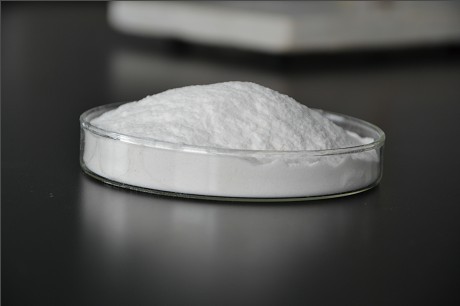

Carboxy Methyl Cellulose, or CMC, is a derivative of cellulose – the main component of plant cell walls. It is a water-soluble polymer that is commonly used in various industries such as food and beverage, pharmaceuticals, and cosmetics. CMC has gained significant popularity in recent years due to its versatility and unique properties.

In this section, we will delve deeper into what CMC is, how it is produced, and its various applications.

What is Carboxy Methyl Cellulose?

As mentioned earlier, CMC is derived from cellulose. It is made by chemically modifying natural cellulose through etherification with chloroacetic acid. This modification process introduces carboxymethyl groups (-CH2COOH) onto the cellulose backbone, resulting in a highly stable and water-soluble polymer.

The degree of substitution (DS) determines the number of carboxymethyl groups present on each anhydroglucose unit (AGU) of the cellulose chain. The higher the DS value, the more hydrophilic and soluble the CMC becomes.

How is CMC Produced?

CMC can be produced from different raw materials such as cotton linters or wood pulp. Cotton linters are short fibers found on cotton seeds after ginning while wood pulp comes from plant-based materials such as trees or bamboo.

History and development of CMC in Nigeria and Africa

CMC, or Carboxy Methyl Cellulose, has been a widely used and well-known product in the global market for quite some time now. However, its history and development in Nigeria and Africa is a relatively recent phenomenon.

The use of CMC as an ingredient in various industries such as food, pharmaceuticals, cosmetics, and others dates back to the early 1900s when it was first discovered by German chemist, Wilhelm Rudolph Fittig. Its properties of being a water-soluble polymer with thickening and stabilizing abilities were quickly recognized and utilized in various industrial applications.

In the late 1960s, CMC production started in Nigeria with just one small factory producing low-quality CMC for local consumption. The demand for CMC grew steadily due to its versatility and cost-effectiveness compared to other thickeners and stabilizers. This led to the establishment of more factories producing CMC which helped meet the growing demand not only in Nigeria but also in neighboring African countries.

However, it wasn’t until the 1990s that CMC production saw significant growth due to improvements in technology and manufacturing processes. With these advancements came better quality products that met international standards, making Nigerian-produced CMC competitive on a global scale.

Today, Nigeria boasts several large-scale CMC production facilities with advanced machinery imported from Europe and Asia.

Benefits and uses of CMC in various industries (food, pharmaceuticals, cosmetics, etc.)

Carboxy Methyl Cellulose (CMC) is a versatile and widely used chemical compound that has revolutionized various industries, including food, pharmaceuticals, cosmetics, and many others. This powerful ingredient has gained popularity in recent years due to its unique properties and numerous benefits. In this section, we will explore the different uses of CMC in various industries and how it has become a game-changer in Nigeria and Africa.

Food Industry:

One of the main applications of CMC is in the food industry, where it acts as a thickening agent and stabilizer. It is commonly used in processed foods such as sauces, dressings, ice cream, yogurt, and baked goods. CMC helps to improve the texture and mouthfeel of these products by providing a smooth consistency. It also prevents ingredients from separating or settling at the bottom of packaged products.

Moreover, CMC is an excellent emulsifier that can bind oil and water-based ingredients together. This property makes it ideal for use in salad dressings, mayonnaise, and other condiments. Additionally, CMC increases the shelf life of food products by preventing bacterial growth.

Pharmaceutical Industry:

In the pharmaceutical industry, CMC plays a crucial role as an excipient – an inactive ingredient that helps to deliver active ingredients effectively into medications. It is commonly used in tablets as a binder to hold them together during production. Its adhesive properties help create compressed tablets with consistent weight and thickness.

Production and supply of CMC in Nigeria and Africa

Carboxy Methyl Cellulose (CMC) has gained popularity in recent years as a versatile and cost-effective additive in various industries. Nigeria, being one of the largest economies in Africa, has also seen a significant rise in demand for CMC for both domestic consumption and export purposes. In this section, we will explore the production and supply of CMC in Nigeria and its impact on the larger African market.

Production of CMC in Nigeria:

The production of CMC in Nigeria is primarily concentrated in the southern part of the country, particularly in Ogun State. The leading producers include companies like BCI Chemical Corporation Ltd, which has a state-of-the-art manufacturing plant that produces high-quality CMC for various applications. These companies use locally sourced raw materials such as wood pulp or cotton linter to produce CMC using advanced technology and processes.

Apart from large-scale manufacturers, there are also many small-scale producers scattered across different regions of Nigeria. This decentralized approach to production ensures that there is a steady supply of CMC throughout the country.

Supply chain:

The supply chain for CMC starts with raw material sourcing from local farmers and suppliers. The raw materials undergo rigorous quality checks before being sent to manufacturing plants where they are processed into high-grade CMC powder or granules.

From here, the finished product is either sold directly to end-users or exported to other countries within Africa or beyond.

Success stories of businesses using CMC in their products

CMC, or Carboxy Methyl Cellulose, is a versatile ingredient that has been steadily gaining popularity in the industrial and consumer product sectors. This naturally occurring compound derived from cellulose has a wide range of applications including food production, pharmaceuticals, personal care products, and household goods. In this section, we will explore some success stories of businesses that have incorporated CMC into their products and have experienced significant improvements in quality and efficiency.

1. Food Industry:

One sector where CMC has made a notable impact is the food industry. Many manufacturers have started using CMC as a thickener and stabilizer in various food products such as sauces, dressings, ice cream, and even gluten-free baked goods. One such success story comes from a leading food manufacturer in Nigeria who was struggling to keep their sauces from separating during storage or transportation. The addition of CMC not only improved the texture and stability of their sauces but also reduced production costs by replacing more expensive thickeners.

2. Pharmaceutical Industry:

In the pharmaceutical industry, CMC is widely used as an excipient in tablet formulations due to its excellent binding properties. A local Nigerian company recently introduced a new herbal supplement that needed to be compressed into tablets for easy consumption. By incorporating CMC as a binder in their formulation, they were able to achieve consistent tablet hardness and disintegration time while reducing the amount of active ingredients required per dose.

Challenges and solutions for using CMC in developing countries like Nigeria

Challenges and Solutions for Using CMC in Developing Countries like Nigeria

While carboxy methyl cellulose (CMC) has shown great potential as a game-changer in Nigeria and other developing countries in Africa, its widespread adoption and usage still face some challenges. In this section, we will discuss the main obstacles that hinder the use of CMC in developing countries like Nigeria and provide possible solutions to overcome them.

1. Lack of Awareness and Education: One of the major barriers to the use of CMC in developing countries is a lack of awareness and education about its benefits and applications. Many people are not familiar with this versatile ingredient, which limits its demand and usage. This is especially true for small-scale businesses where owners may not have access to information about new products or ingredients.

Solution: To address this challenge, there needs to be more efforts put towards educating people about CMC’s properties and potential uses. This can be done through campaigns, workshops, seminars, and training programs organized by government agencies or industry associations. Additionally, manufacturers should also educate their customers on how to use CMC effectively in their products.

2. Limited Supply Chain Infrastructure: Another significant challenge for using CMC in developing countries is the limited supply chain infrastructure. Inadequate transportation systems, poor storage facilities, and inefficient distribution networks make it difficult for businesses to source CMC reliably at competitive prices.

Solution: Governments should invest more resources into improving infrastructure such as road networks, warehouses, cold storage facilities, etc.,

Future prospects for the growth of CMC in Nigeria and Africa

The future prospects for the growth of CMC (Carboxy Methyl Cellulose) in Nigeria and Africa are highly promising. With the increasing demand for eco-friendly and sustainable products, CMC is expected to play a crucial role in various industries, driving its growth in the region.

One of the major factors contributing to the potential growth of CMC in Nigeria and Africa is its versatility. CMC has a wide range of applications across industries such as food and beverage, pharmaceuticals, personal care, textiles, paper and pulp, oil drilling, and construction. This makes it an attractive product for manufacturers looking for cost-effective solutions with multiple uses. Moreover, advancements in technology have made it possible to produce high-quality CMC at a lower cost, making it accessible to small and medium enterprises as well.

In recent years, there has been a surge in awareness about sustainable packaging materials among consumers. This has led to an increase in demand for biodegradable alternatives to traditional plastics. CMC-based packaging offers an environmentally friendly solution that is also cost-effective compared to other biodegradable options like PLA or PHA. As governments across Africa are implementing policies promoting sustainable practices, the demand for CMC-based packaging is expected to rise significantly.

Another key driver for the growth of CMC in Nigeria and Africa is its use in the textile industry. The region’s textile industry has witnessed considerable growth over the past few years due to rising consumer spending power and government initiatives supporting local production.

Comments are closed.