Enhancing Industrial Processes with Magnetic Separators from Wigmore Trading in Nigeria

Enhancing Industrial Processes with Magnetic Separators from Wigmore Trading in Nigeria

In the fast-paced world of industrial processes, efficiency is key. And when it comes to separating materials and ensuring a smooth workflow, magnetic separators are an invaluable tool. In Nigeria, Wigmore Trading offers top-of-the-line magnetic separators that can revolutionize your operations. Join us as we explore how these innovative tools can enhance your industrial processes and take your business to the next level.

Introduction to Magnetic Separators

Introduction to Magnetic Separators

Magnetic separators are powerful tools used in various industries to remove unwanted magnetic materials from products, processes, and production lines. These devices use the principle of magnetic attraction and repulsion to separate ferrous metals from non-ferrous materials, ensuring product purity, enhancing safety, and improving overall efficiency.

At Wigmore Trading Nigeria, we understand the importance of efficient industrial processes and the need for high-quality magnetic separation equipment. That’s why we offer a wide range of top-of-the-line magnetic separators designed to meet the specific needs of different industries.

In this section, we will provide an overview of magnetic separators, their types, applications, and benefits.

Types of Magnetic Separators

There are several types of magnetic separators available in the market today. The most common ones include:

1. Overband Magnets – also known as cross-belt magnets or suspended magnets; these are used for continuous removal of tramp metal from conveyor belts.

2. Drum Magnets – consist of a rotating drum with powerful magnets inside that attract ferrous materials as they pass over them.

3. Magnetic Pulleys – similar to drum magnets but used for smaller particles or higher volumes; ideal for removing ferrous contaminants from free-flowing bulk materials.

4. Plate Magnets – commonly used in chutes or pipelines to remove larger pieces of tramp metal before reaching sensitive processing equipment.

5. Grate Magnets – typically installed in hoppers or bins where materials flow through grids containing strong magnets that capture any ferrous contaminants.

Applications of Magnetic Separators

Magnetic separators have a wide range of applications across various industries such as mining, food processing, pharmaceuticals, plastics manufacturing, recycling plants, and many others. Some common uses include:

1. Ferrous metal removal – prevents damage to machinery by removing any iron or steel objects that may be present in raw materials or finished products.

2. Product purification – ensures the final product is free from any magnetic particles that may affect its quality or safety.

3. Protection of equipment – helps to prolong the lifespan of processing equipment by removing damaging metal contaminants.

Benefits of Magnetic Separators

The use of magnetic separators in industrial processes brings several benefits, which include improved product purity, increased productivity, and enhanced safety. These devices can also help businesses save money by reducing maintenance costs and preventing costly production line shutdowns due to metal contamination.

Magnetic separators play a crucial role in ensuring efficient and safe industrial processes. At Wigmore Trading Nigeria, we pride ourselves on providing high-quality magnetic separation solutions to meet the unique needs of our clients. Stay tuned for our next section where we will dive deeper into how these powerful tools enhance various industries’ processes.

Importance of Magnetic Separators in Industrial Processes

Magnetic separators are crucial tools in various industrial processes, providing an effective and efficient method for separating magnetic materials from non-magnetic ones. These devices are utilized in a wide range of industries, including mining, food processing, pharmaceuticals, and waste management. The importance of magnetic separators cannot be overstated as they play a vital role in enhancing the quality of products and ensuring the smooth operation of industrial processes.

One of the primary uses of magnetic separators is in the mineral processing industry. In this sector, these devices are used to remove unwanted ferrous particles from valuable minerals such as iron ore, coal, and rare earth elements. By eliminating these impurities during the extraction process, magnetic separators help to improve the purity and quality of the final product. This not only increases its value but also reduces the risk of equipment damage or failure caused by metal contaminants.

In addition to mineral processing, magnetic separators are also essential in food manufacturing plants. Food safety is a top priority for any food production facility, and contamination with metal fragments can have severe consequences for both consumers’ health and a company’s reputation. Magnetic separators are used to remove small pieces of stainless steel or other ferrous metals that may have accidentally entered the production line through machinery wear or packaging materials. This prevents potential hazards while maintaining product integrity.

The pharmaceutical industry also relies heavily on magnetic separators to ensure product quality and safety. During drug manufacturing processes, it is crucial to eliminate any traces of metal contamination that could compromise drug efficacy or pose health risks to consumers. Magnetic separators effectively perform this task by attracting and removing even tiny metal particles present in raw materials or equipment parts.

Waste management facilities also benefit greatly from using magnetic separators in their sorting processes. These devices can separate ferrous materials from non-ferrous ones quickly and efficiently without manual labor intervention. This helps increase recycling rates while reducing landfill waste.

Incorporating magnetic separators into industrial processes has numerous benefits beyond simply removing unwanted metal particles. They also improve product quality, increase operational efficiency, and contribute to a safer working environment. In Nigeria’s industrial sector, where the demand for high-quality products is steadily increasing, using magnetic separators from Wigmore Trading can provide significant advantages to companies looking to stay competitive in the market.

Understanding Wigmore Trading and their Role in Nigeria

Understanding Wigmore Trading and their Role in Nigeria

Wigmore Trading is a leading supplier of industrial equipment, including magnetic separators, in Nigeria. The company was founded in 2002 and has since become a trusted partner for businesses looking to enhance their industrial processes.

One of the key aspects that sets Wigmore Trading apart is their commitment to providing high-quality products at competitive prices. This has made them a go-to choice for many industries, from mining to food processing, in Nigeria. Additionally, Wigmore Trading prides itself on its excellent customer service and technical support, ensuring that clients have access to assistance whenever needed.

With a strong focus on innovation and technology, Wigmore Trading stays ahead of the curve by constantly improving and updating their product offerings. This includes providing state-of-the-art magnetic separators that are designed to meet the specific needs of each industry they serve. These separators use powerful magnets to remove unwanted ferrous materials from different types of liquids or dry materials, ensuring cleaner end-products and more efficient production processes.

But what makes Wigmore Trading truly stand out is their understanding of the unique challenges faced by businesses operating in Nigeria. The country’s economy is heavily reliant on its oil industry; however, there has been a growing effort towards diversification into other sectors such as agriculture and manufacturing. This shift presents new opportunities for companies like Wigmore Trading to support these emerging industries with top-quality equipment.

Moreover, as a proudly Nigerian-owned company, Wigmore Trading understands the importance of supporting local businesses in achieving their development goals. They work closely with clients to understand their specific needs and provide tailored solutions that meet those requirements effectively. This personalized approach has earned them an excellent reputation among both local and international clients.

In addition to supplying high-quality magnetic separators, Wigmore Trading also offers comprehensive training programs for operators on how to properly handle and maintain these specialized machines. With this hands-on training provided by experienced professionals, businesses can ensure the longevity and optimal performance of their equipment.

Wigmore Trading plays a vital role in enhancing industrial processes in Nigeria through their commitment to delivering top-quality products, excellent customer service, and continuous innovation. Their understanding of the local market and dedication to supporting Nigerian businesses make them an essential partner for any industry looking to improve efficiency and productivity.

Types of Magnetic Separators Offered by Wigmore Trading

Wigmore Trading offers a wide range of magnetic separators to cater to the diverse needs and requirements of industrial processes in Nigeria. These magnetic separators are designed and manufactured using advanced technology, ensuring high efficiency and effectiveness in separating different types of materials.

Let’s take a closer look at the various types of magnetic separators offered by Wigmore Trading:

1. Magnetic Drum Separators:

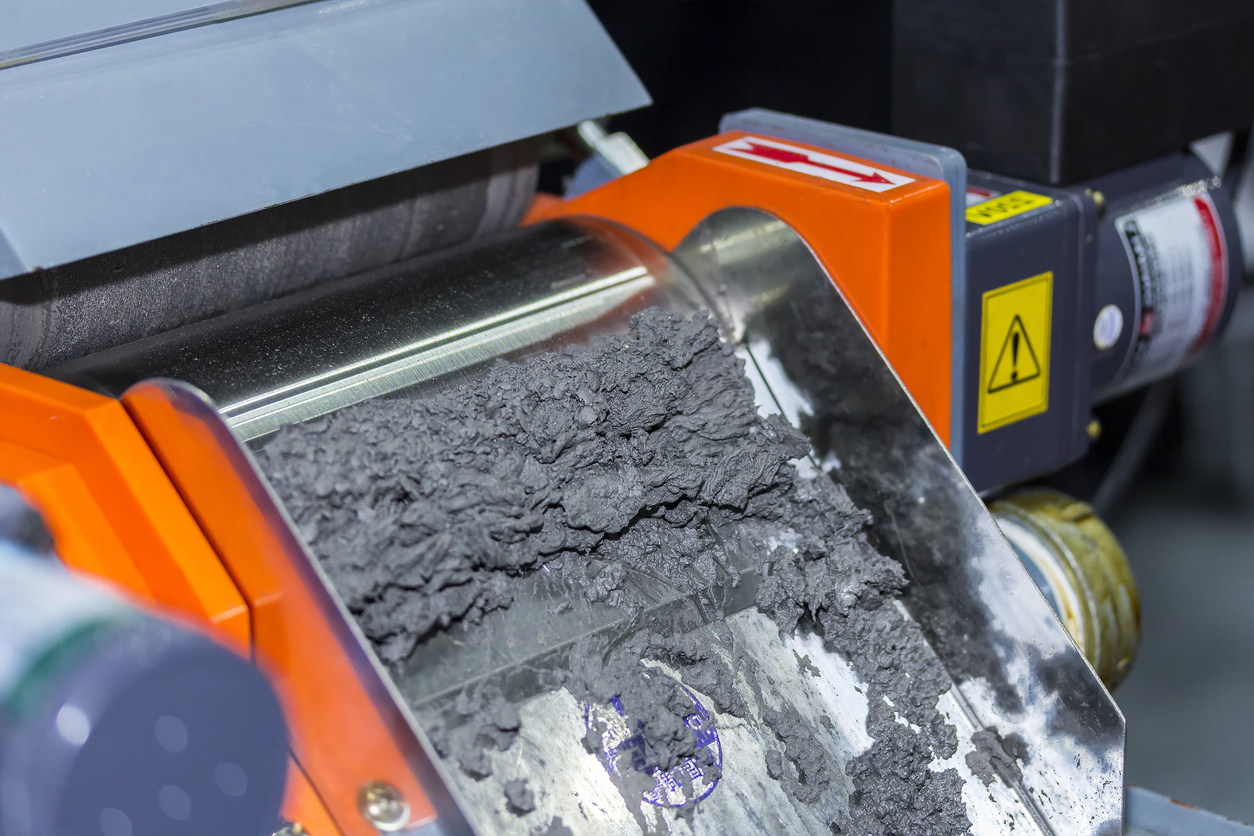

These separators consist of a rotating drum with powerful magnets inside that attract ferrous contaminants from the material being processed. The ferrous particles are then carried away from the material flow and collected separately, ensuring clean and contaminant-free end products.

2. Magnetic Pulley Separators:

Magnetic pulley separators are designed to remove tramp iron and other ferromagnetic contaminants from conveyor belts, chutes, or other material handling systems. They consist of a permanent magnetic pulley mounted on a shaft with bearings for easy installation. These separators are ideal for applications where large quantities of bulk materials need to be processed continuously.

3. Magnetic Plate Separators:

As the name suggests, these separators have a flat plate surface with strong magnets embedded within them. They are commonly used in industries such as food processing, pharmaceuticals, and plastics to remove small ferrous particles that may contaminate the final product.

4. Magnetic Grate Separators:

Similar to plate separators, magnetic grate separators also have strong magnets embedded in a grid-like structure instead of a flat plate surface. This design allows for better contact between the magnet and the material being processed, making it highly effective in removing fine ferrous particles.

5. Overband Magnetic Separators:

Overband magnetic separators are designed to remove large pieces of tramp iron from conveyor belts or other material handling systems. These powerful magnets can easily suspend over conveyors without any support or modification needed for installation.

6. Electromagnetic Suspended Separator:

This type of separator uses an electromagnet instead of permanent magnets for separation. The advantage of this separator is that the magnetic field strength can be adjusted according to the specific needs of the application.

Wigmore Trading offers a comprehensive range of magnetic separators to cater to various industrial processes in Nigeria. These separators not only ensure efficient and effective separation but also contribute to maintaining a clean and safe working environment. Trust Wigmore Trading for all your magnetic separation needs and experience enhanced productivity in your industrial processes.

Benefits of Using Magnetic Separators from Wigmore Trading

Magnetic separators are powerful tools that have been used in various industries for many years. These devices use the power of magnets to separate and remove unwanted materials from different substances. In recent times, their popularity has skyrocketed due to their effectiveness in enhancing industrial processes across Nigeria. This is where Wigmore Trading comes into play with their range of high-quality magnetic separators.

There are several benefits of using magnetic separators from Wigmore Trading, which make them a must-have for any industrial process. Let’s take a closer look at these benefits:

1) Improves Product Quality: One of the primary benefits of using magnetic separators is that they improve the overall quality of products by removing any unwanted or potentially harmful materials. In industries such as food processing and pharmaceuticals, it is crucial to ensure that the end product is free from impurities and contaminants. Magnetic separators efficiently filter out metal particles, ensuring that the final product meets quality standards.

2) Increases Efficiency: Another significant advantage of using magnetic separators is that they help increase process efficiency. By eliminating unwanted materials, these devices prevent clogging and jamming in machinery, leading to smoother operations and reduced downtime. This ultimately translates into increased productivity and cost savings for businesses.

3) Protects Equipment: Metal particles can cause severe damage to equipment if left unchecked during industrial processes. Magnetic separators work as a protective barrier by capturing ferrous particles before they can enter sensitive machinery or contaminate products. This helps prolong the lifespan of equipment and reduces maintenance costs.

4) Versatile Applications: Magnetic separators from Wigmore Trading can be used in various industries such as mining, recycling, ceramics, plastics, textiles, among others. They are versatile enough to handle different types of materials like dry granules or wet slurries with equal efficiency.

5) Environmentally Friendly: Using magnetic separators is an eco-friendly solution as it reduces waste generation by removing metals and other contaminants from materials before disposal or recycling. This not only benefits the environment but also helps businesses comply with environmental regulations.

Using magnetic separators from Wigmore Trading has several benefits that can significantly enhance industrial processes in Nigeria. From improving product quality to increasing efficiency and protecting equipment, these devices are a valuable addition to any production line. Furthermore, their versatility and eco-friendly nature make them an ideal choice for businesses looking to streamline their operations while reducing their environmental impact.

Case Studies: Real-life Examples of Enhanced Industrial Processes with Wigmore Trading’s Magnetic Separators

Case studies are essential in showcasing the tangible benefits of using magnetic separators in various industrial processes. Through these real-life examples, we can see how Wigmore Trading’s magnetic separators have enhanced the efficiency and productivity of different companies across Nigeria.

One such case study is that of a steel manufacturing company in Lagos, Nigeria. Prior to implementing Wigmore Trading’s magnetic separators, the company faced significant issues with metal contamination in their final product. This not only resulted in customer complaints but also led to costly production delays and equipment damage. After consulting with Wigmore Trading experts and installing their high-quality magnetic separators, the company saw a drastic reduction in metal contamination levels. As a result, their final product was of higher quality, leading to increased customer satisfaction and reduced costs due to fewer production delays and equipment repairs.

Another success story comes from an oil refinery plant in Port Harcourt, Nigeria. The plant used large rotating drums for separating impurities from crude oil during the refining process. However, these drums were prone to breakdowns due to constant exposure to ferrous particles present in the crude oil. This resulted in frequent maintenance shutdowns and loss of production time. Upon switching to Wigmore Trading’s powerful magnetic drum separators, the plant saw a remarkable decrease in breakdowns and maintenance costs as ferrous particles were efficiently removed from the crude oil before it entered the drums.

In addition to improving product quality and reducing equipment downtime, Wigmore Trading’s magnetic separators have also helped companies increase their overall operational efficiency. For instance, a plastics manufacturing plant based in Abuja experienced significant improvement after incorporating Wigmore Trading’s inline magnetic filters into their production line. These filters effectively captured any ferrous contaminants present in raw materials before entering processing machines, resulting in reduced machine wear-and-tear and fewer interruptions during production runs.

These are just some examples of how different industries have benefited from using high-quality magnetic separators from Wigmore Trading. The versatility of these products makes them suitable for a wide range of industrial processes, from food processing to mining and beyond. Companies across Nigeria have seen a significant return on their investment in Wigmore Trading’s magnetic separators, with improved product quality, increased efficiency, and reduced costs.

These case studies demonstrate how Wigmore Trading’s magnetic separators have played a crucial role in enhancing industrial processes across different sectors in Nigeria. Their commitment to providing top-notch products and exceptional customer service has made them the go-to choice for companies looking to improve their operations. With continued innovation and advancements in technology, Wigmore Trading is set to revolutionize the industrial landscape in Nigeria further.

How to Choose the Right Magnetic Separator for Your Industry?

Magnetic separators are essential industrial tools that are used to remove unwanted magnetic materials from a variety of products. These powerful devices come in different sizes, shapes, and strengths, making it crucial to choose the right one for your specific industry needs. With the wide range of options available in the market, selecting the perfect magnetic separator can seem like a daunting task. In this section, we will guide you through the key factors to consider when choosing a magnetic separator for your industry.

1. Understand Your Product Characteristics:

The first step in selecting the right magnetic separator is to understand the characteristics of your product. This includes its size, shape, conductivity, and magnetic properties. For example, if you are dealing with small particles or granular materials, an inline magnetic separator would be more suitable compared to a plate magnet which is better suited for larger pieces.

2. Determine Your Separation Requirements:

Different industries have varying separation requirements depending on their production processes and end goals. Some industries may only need basic ferrous metal separation while others may require more advanced systems for removing both ferrous and non-ferrous metals. It is important to clearly define your separation needs before deciding on a specific type of magnetic separator.

3. Consider Installation Location:

The installation location of the magnetic separator plays a significant role in its effectiveness and efficiency. Factors such as space availability and flow rate should be considered when choosing between permanent or electromagnetic separators as well as whether it should be placed above or below conveyor belts or suspended over chutes.

4. Evaluate Maintenance Needs:

Maintenance is an inevitable part of any industrial equipment and magnetic separators are no exception. Some types require regular cleaning while others may need replacement parts after extended use. It is important to factor in these maintenance needs when selecting a magnetic separator so that it does not disrupt your production process.

5.Explore Different Designs:

Magnetic separators come in various designs such as drum magnets, grate magnets, pulley magnets, and more. Each design has its own unique features and benefits that can cater to specific industries and applications. It is recommended to research and explore different designs before making a decision.

Choosing the right magnetic separator for your industry requires careful consideration of your product characteristics, separation needs, installation location, maintenance requirements, and exploring different designs. By taking these factors into account, you can ensure that you invest in a magnetic separator that will effectively enhance your industrial processes and improve overall productivity.

Future of Magnetic Separators in Nigeria with Wigmore Trading

The future of magnetic separators in Nigeria looks promising with the availability of high-quality products from Wigmore Trading. As one of the leading suppliers of industrial equipment in Nigeria, Wigmore Trading has been at the forefront of introducing cutting-edge technologies to enhance various industries. Magnetic separators are no exception, and their presence in industrial processes is only set to increase in the coming years.

One of the main reasons for this predicted growth is the versatility and efficiency of magnetic separators. These devices use powerful magnets to attract and remove unwanted metallic particles from production materials, thus improving product quality and reducing downtime. In a country like Nigeria where industries such as mining, agriculture, food processing, and manufacturing are booming, these benefits are crucial for maintaining a competitive edge.

Moreover, with increasing concerns about environmental pollution and health hazards caused by metal contaminants in consumer goods, there is a growing demand for stricter quality control measures. This has led to a rise in the adoption of magnetic separators as an effective solution for removing even the smallest traces of metals from raw materials or finished products.

Wigmore Trading offers a wide range of magnetic separators suitable for different types of industries and applications. Their product line includes permanent magnetic pulleys, drum type magnetic separators, plate type magnetic separators, overband/crossbelt magnets, among others. These products have been carefully selected from reputable manufacturers known for their expertise in producing reliable and durable equipment.

But it’s not just about providing high-quality products; Wigmore Trading also focuses on offering exceptional customer service through prompt delivery times and expert technical support. With their team of experienced professionals who understand the unique needs and challenges faced by Nigerian industries, they provide tailored solutions that meet specific requirements.

Furthermore, Wigmore Trading constantly strives to stay up-to-date with industry advancements and technological innovations related to magnetic separation. This ensures that they can offer state-of-the-art products that cater to evolving industrial demands while keeping prices competitive.

As more Nigerian industries recognize the benefits of using magnetic separators and turn to trusted suppliers like Wigmore Trading, the future for these devices in the country is looking bright. With their commitment to quality and customer satisfaction, Wigmore Trading is well-positioned to play a significant role in enhancing industrial processes with magnetic separators in Nigeria.

–

Magnetic separators play a crucial role in enhancing industrial processes, especially in industries handling large quantities of materials. With the advancement of technology, magnetic separators have become essential tools for efficient and cost-effective material separation.

At Wigmore Trading Nigeria Limited, we offer a wide range of magnetic separators that are designed to meet the diverse needs of various industries. Our products are specially selected from top manufacturers worldwide, ensuring high-quality performance and reliability.

One of our popular magnetic separator options is the drum-type magnetic separator. This type of separator consists of a rotating drum with powerful magnets placed inside. When materials pass through the drum, the magnets attract and hold onto any ferrous impurities present in the material, separating them from the rest. The separated impurities can then be easily removed using an automated cleaning mechanism or manually by stopping the rotation of the drum.

Another commonly used option is the plate-type magnetic separator. This type consists of a series of magnetized plates arranged parallel to each other with a gap between them. As materials flow through this gap, any ferrous particles get attracted to these plates and stick to them until they are manually removed for cleaning.

For more specialized applications, we also offer high-intensity magnetic separators that use extremely powerful magnets to remove even tiny ferrous particles from bulk materials. These are often used in industries dealing with fine powders or liquids where traditional methods may not be sufficient.

Our team at Wigmore Trading understands that every industry has its unique needs and challenges when it comes to material separation. That’s why we also offer customized solutions tailored specifically for our clients’ requirements. We work closely with our customers to understand their processes and provide them with optimal solutions that improve efficiency and reduce downtime.

Apart from separating ferrous impurities from raw materials or finished products, our magnetic separators also prevent equipment damage caused by metal contaminants entering sensitive machinery such as crushers or conveyors. This results in fewer breakdowns and saves on maintenance costs.

Wigmore Trading’s magnetic separators are a cost-effective and efficient solution for enhancing industrial processes in various industries. With our high-quality products and personalized services, we aim to provide the best solutions for our clients’ material separation needs. Contact us today to learn more about our wide range of magnetic separators and how they can benefit your business.

Comments are closed.