From Production to Delivery: Exploring Our Nitric Acid Supply Chain in Nigeria

From Production to Delivery: Exploring Our Nitric Acid Supply Chain in Nigeria

Welcome to our blog, where we take you on a fascinating journey through the intricacies of our nitric acid supply chain in Nigeria. Join us as we unveil the behind-the-scenes operations from production to delivery, delving into the challenges and triumphs that shape this vital industry. Whether you’re curious about the chemical processes involved or simply interested in understanding how we ensure a seamless flow of this essential substance, prepare to be captivated by an exploration like no other. So buckle up and get ready for an eye-opening adventure into the heart of our nitric acid supply chain.

Introduction to Nitric Acid: What is it and its uses in various industries?

Introduction to Nitric Acid: What is it and its uses in various industries?

Nitric acid, also known as aqua fortis or spirit of niter, is a highly corrosive mineral acid with the chemical formula HNO3. It is a clear, colorless liquid with a pungent odor and is commonly used in various industrial processes.

Nitric acid is primarily produced by the oxidation of ammonia through the Ostwald process. This involves reacting ammonia with oxygen and water vapor over a platinum/rhodium catalyst at high temperatures. The resulting nitric oxide gas is then further oxidized using air to form nitrogen dioxide, which is finally dissolved in water to produce nitric acid.

The production of nitric acid requires specialized equipment and careful handling due to its highly reactive nature. It must be stored and transported in special containers made of materials that are resistant to corrosion, such as stainless steel or glass.

But why is nitric acid so important? Let’s explore its uses in various industries:

1. Fertilizer Production:

One of the key uses of nitric acid is in the manufacturing of fertilizers. It plays a vital role in converting ammonia into ammonium nitrate – a compound widely used as an agricultural fertilizer due to its high nitrogen content. Ammonium nitrate helps improve soil fertility, increase crop yields, and promote healthy plant growth.

Understanding the Production Process of Nitric Acid: From raw materials to end product.

Nitric acid is a highly versatile and important chemical compound that is widely used in various industries such as agriculture, pharmaceuticals, and manufacturing. It is produced through a multi-step chemical process involving the conversion of raw materials into the end product – nitric acid. In this section, we will take a closer look at the production process of nitric acid, from its raw materials to the final product.

Raw Materials:

The main raw material for producing nitric acid is ammonia. Other essential inputs include air, water, and energy sources such as natural gas or electricity. Ammonia can be obtained through the Haber-Bosch process, where nitrogen from air is combined with hydrogen derived from natural gas under high pressure and temperature conditions.

Oxidation:

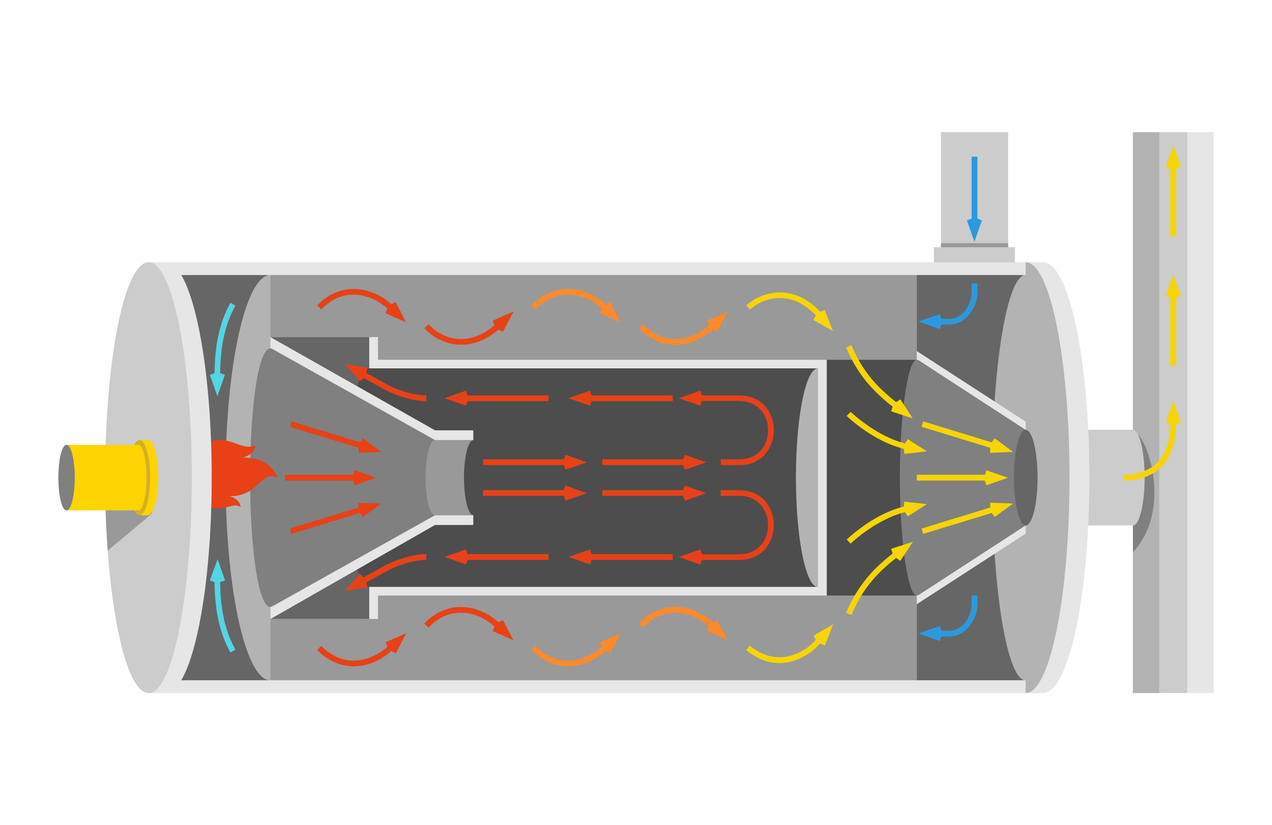

The first step in the production process involves oxidizing ammonia into nitric oxide (NO). This reaction takes place in a catalytic reactor at temperatures between 800-1000°C in the presence of oxygen. The reaction produces NO gas along with water vapor.

Absorption:

Next, NO gas is cooled and purified before being absorbed into water to form nitrous (HNO3) and nitric oxide (NO2) acids. This absorption process occurs in an absorption tower equipped with packed beds or trays where gases bubble up while liquids flow down.

Our Role in the Nitric Acid Supply Chain: How we procure and distribute Nitric Acid in Nigeria.

Our Role in the Nitric Acid Supply Chain: How we procure and distribute Nitric Acid in Nigeria

Nitric acid is a crucial chemical compound used in various industries, including fertilizers, explosives, and pharmaceuticals. As one of the leading suppliers of nitric acid in Nigeria, our role in the supply chain is essential to ensure a steady and reliable supply of this vital chemical.

Procurement Process

The procurement process for nitric acid begins with identifying reputable manufacturers who can provide us with high-quality products at competitive prices. We have established long-term relationships with trusted suppliers worldwide, ensuring a consistent supply of nitric acid throughout the year.

Once we have selected our suppliers, we carefully negotiate contracts to secure favorable terms and conditions for both parties. This includes determining delivery schedules, quality control measures, and pricing structures.

Quality Control

As part of our commitment to providing top-grade nitric acid to our customers, we have strict quality control measures in place during the procurement process. Our team conducts regular on-site inspections at supplier facilities to ensure that they meet international standards for production and handling.

Distribution Process

After procuring nitric acid from trusted manufacturers, it is transported by road or rail to our storage facilities strategically located across Nigeria. These facilities are equipped with state-of-the-art technology to maintain optimal storage conditions for nitric acid.

From there, our logistics team works closely with transportation companies to schedule timely deliveries based on customer demand.

Partnerships with Reputable Producers: An insight into our partnerships and how they benefit our customers.

Partnerships are an integral part of our nitric acid supply chain in Nigeria. We understand the importance of collaborating with reputable producers to ensure the highest quality and timely delivery of our products to our customers. In this section, we will provide an insight into our partnerships and how they benefit not only us but also our valued customers.

At [Company Name], we have established strong partnerships with some of the most reputable producers in the country. Our selection process for partners is rigorous and includes thorough research on their production processes, quality control measures, and reputation in the market. This ensures that we work with only those who adhere to the highest standards of production and share our commitment to delivering top-quality nitric acid to our customers.

One of our key partnerships is with [Partner Company Name], a leading producer of nitric acid in Nigeria. They have been in operation for over 20 years and have a well-established track record of producing high-grade nitric acid using advanced technology and strict quality control measures. Our collaboration with them has allowed us to access a steady supply of top-quality nitric acid at competitive prices, which ultimately benefits our customers.

In addition to sourcing from reputable producers, we also work closely with them to improve efficiency in our supply chain. This includes regular communication regarding production schedules and inventory levels, as well as forecasting demand from our end so that they can plan their operations accordingly.

Challenges in the Supply Chain: Exploring potential challenges and how we overcome them.

The supply chain for nitric acid in Nigeria is a complex and intricate process that involves numerous stakeholders and steps. While the end goal is to ensure a smooth flow from production to delivery, there are several challenges that can arise at various stages of the supply chain.

In this section, we will explore some of the potential challenges that can be encountered in the nitric acid supply chain in Nigeria and how we overcome them.

1. Supply Shortages:

One of the main challenges in any supply chain is ensuring a steady and reliable supply of raw materials. In the case of nitric acid, which is primarily produced through the oxidation of ammonia, any shortage or disruption in ammonia availability can cause severe disruptions in the entire supply chain.

To overcome this challenge, our company has established partnerships with multiple suppliers who provide us with a constant supply of high-quality ammonia. We also have contingency plans in place to quickly source alternative suppliers if necessary.

2. Production Delays:

Another major challenge that can impact our nitric acid supply chain is production delays. This could be due to technical issues, equipment breakdowns, or other unforeseen circumstances.

To mitigate these risks, we have invested heavily in state-of-the-art production facilities and machinery to ensure maximum efficiency and minimize downtime. Additionally, regular maintenance checks and backup systems are put in place to quickly resume production if any disruptions occur.

3. Transportation Issues:

Transportation plays a crucial role in delivering nitric acid from our production plants to our customers across Nigeria.

Delivery and Distribution

Delivery and distribution are crucial aspects of the nitric acid supply chain in Nigeria. These processes involve the transportation of the product from production sites to various industries and markets across the country. In this section, we will delve into the details of how nitric acid is delivered and distributed, as well as the challenges and solutions involved.

The journey of nitric acid begins at production plants where it is manufactured using ammonia or air oxidation processes. Once produced, it is then transported in bulk via road tankers or rail tank cars to storage facilities. These facilities serve as temporary holding areas before the product is further distributed to end-users.

One of the main challenges faced in delivery and distribution is ensuring timely and efficient transport of nitric acid to its intended destinations. The vast size of Nigeria poses a significant logistical challenge, with long distances between production sites and end-use locations. This can result in delays, which can be costly for both producers and consumers.

To overcome these challenges, many companies have invested in their own fleet of specialized trucks for delivery purposes. This allows them to have more control over transportation schedules, ensuring that products are delivered on time. Additionally, some companies also use third-party logistics providers who specialize in chemical transportation to ensure safe and timely delivery.

Another critical factor in delivery and distribution is maintaining high levels of safety during transport. Nitric acid is a hazardous substance that requires special handling procedures to prevent accidents or spills that could harm people or damage property.

Comments are closed.