From Quarry to Market: A Sneak Peek into the Dolomite Mining Process at Wigmore Trading

From Quarry to Market: A Sneak Peek into the Dolomite Mining Process at Wigmore Trading

Are you curious about the secrets hidden deep within the earth, waiting to be unearthed and transformed into extraordinary treasures? Join us as we venture into the fascinating world of dolomite mining at Wigmore Trading, where raw nature’s wonders are extracted from quarries and meticulously prepared for market. From the rugged landscapes of extraction sites to the meticulous process behind transforming this remarkable mineral, prepare yourself for an exclusive sneak peek that will leave you awe-inspired. Get ready to embark on a journey through time and witness firsthand how dolomite is brought from quarry to market in a symphony of innovation and dedication!

Introduction to Dolomite Mining and Wigmore Trading

Introduction to Dolomite Mining and Wigmore Trading

Dolomite is a type of sedimentary rock that is composed of calcium magnesium carbonate. It is commonly used in various industries, such as construction, agriculture, and manufacturing. Dolomite mining refers to the process of extracting this valuable mineral from the earth’s surface. At Wigmore Trading, we specialize in dolomite mining and have been supplying high-quality dolomite products to our clients for over a decade.

History of Dolomite Mining at Wigmore Trading

The history of dolomite mining at Wigmore Trading dates back to the early 2000s when our founder, Mr. John Smith, discovered a large deposit of high-grade dolomite on his property in the rural town of Wigmore. Recognizing the potential value of this mineral, he invested in equipment and hired skilled miners to extract it from the ground.

Over the years, with advancements in technology and growing demand for dolomite products globally, our operations have expanded significantly. Today, we are one of the leading suppliers of dolomite in the market with a strong reputation for providing top-quality products.

The Dolomite Mining Process at Wigmore Trading

At Wigmore Trading, we follow a systematic process to mine and refine dolomite before it reaches our customers. The first step is prospecting; our team conducts geological surveys and collects samples from potential sites to determine their quality and quantity.

Once a suitable deposit has been identified, we begin excavation by drilling holes into the ground using specialized machinery.

What is Dolomite and Why is it Important?

What is Dolomite?

Dolomite is a mineral that is composed of calcium magnesium carbonate, with the chemical formula CaMg(CO3)2. It usually forms in sedimentary rocks and can be found in abundance all over the world. The name ‘dolomite’ is derived from the French mineralogist Déodat Gratet de Dolomieu, who was the first to describe it as a distinct mineral.

Why is it Important?

1. Industrial Uses:

Dolomite has a wide range of industrial uses, making it an important mineral for various industries. It is used as a flux material in steelmaking and also plays a crucial role in the production of glass, ceramics, and fertilizers. Its high magnesium content makes it ideal for manufacturing refractory bricks that are used in furnaces and kilns.

2. Agriculture:

Dolomite is essential for agricultural practices as it serves as an excellent source of both magnesium and calcium nutrients for plants. These minerals play a vital role in regulating soil pH levels and promoting healthy plant growth.

3. Construction Materials:

Due to its hardness and durability, dolomite is also widely used as a construction material. It can be crushed into small particles to create gravel or sand which can be used in concrete mixes or road construction projects.

4. Water Treatment:

In addition to being used as an ingredient in water treatment processes, dolomite also helps to neutralize acidic waters by increasing their alkalinity levels.

The Process of Extracting Dolomite from a Quarry

Dolomite is a mineral that is commonly used in various industries, including construction, agriculture, and manufacturing. It is a type of limestone that contains high levels of magnesium and calcium carbonate, making it a valuable resource for many applications. But how does this mineral go from its natural form in a quarry to being processed and sold in the market? In this section, we will take a closer look at the process of extracting dolomite from a quarry.

1. Locating the Quarry:

The first step in extracting dolomite from a quarry is to locate suitable deposits of the mineral. This involves conducting surveys and geological studies to identify areas with high concentrations of dolomite. The location of the quarry should also have easy access to transportation routes for efficient distribution.

2. Obtaining Permits:

Before any extraction can occur, companies must obtain all necessary permits from local authorities. These permits ensure that all environmental regulations are followed and protect the surrounding communities from potential harm.

3. Clearing and Stripping:

Once all permits are obtained, the next step is to clear and strip away any overburden or vegetation on top of the dolomite deposit to expose the mineral-rich layers underneath. This process can be done manually or with heavy machinery depending on the size and depth of the quarry.

How Wigmore Trading Ensures High Quality Dolomite

At Wigmore Trading, we pride ourselves on providing our customers with high quality dolomite that meets their specific needs and requirements. We understand the importance of using only the best materials in construction and agricultural projects, which is why we have implemented a rigorous process to ensure the quality of our dolomite.

1. Careful Selection of Raw Materials

The first step in ensuring high quality dolomite is the careful selection of raw materials from our quarry. We have a team of experts who carefully inspect and analyze different areas of the quarry to identify the best quality dolomite rocks. This includes testing for purity, density, and chemical composition.

2. State-of-the-art Mining Techniques

Once the ideal location for mining is identified, we use advanced mining techniques to extract the dolomite rocks from the earth. These techniques minimize damage to the environment and ensure that only high-quality rocks are extracted.

3. Crushing and Screening Process

After extraction, the dolomite rocks are transported to our crushing plant where they undergo a series of processes to prepare them for market use. The rocks are crushed into smaller sizes and screened to eliminate any impurities or foreign particles.

4. Quality Control Measures at Every Step

At every stage of processing, we have strict quality control measures in place to ensure that only high-quality dolomite is used in our products. Our team conducts regular inspections throughout each process, checking for consistency in size, shape, color, and density.

The Role of Trusted Miners in the Supply Chain

The mining industry is a crucial part of the global economy, providing raw materials for various industries such as construction, manufacturing, and agriculture. However, with the increasing demand for these resources, there has been a growing concern about ethical practices in the supply chain.

This is where trusted miners play a vital role. These are mining companies that adhere to strict standards and regulations to ensure responsible and sustainable practices throughout the entire mining process. Wigmore Trading is proud to be one of these trusted miners, committed to transparency and accountability in all our operations.

But what exactly is the role of trusted miners in the supply chain? Let’s take a closer look at how they contribute to responsible sourcing and production:

1. Ensuring Compliance with Regulations

Trusted miners must comply with local laws and regulations regarding environmental protection, labor rights, and community engagement. This ensures that their operations do not harm the environment or exploit workers. In addition, they also adhere to international standards such as those set by the United Nations Global Compact (UNGC) and Responsible Mining Index (RMI).

At Wigmore Trading, we go beyond compliance by implementing additional measures to minimize our impact on the environment and support local communities.

2. Promoting Ethical Sourcing

One of the major concerns in mining is unethical sourcing practices such as using forced or child labor in mines. Trusted miners have strict policies against these practices and only work with suppliers who follow ethical guidelines.

From Quarry to Market: The Journey of Dolomite

Dolomite is a versatile and valuable mineral that is used in a variety of industries, from construction to agriculture. But have you ever wondered how this important mineral makes its way from the quarry to the market? In this section, we will take you on a journey through the dolomite mining process at Wigmore Trading and give you an insight into the different stages involved in turning raw dolomite into a marketable product.

1. Extraction: The first step in the journey of dolomite is its extraction from quarries. At Wigmore Trading, we have our own quarries where dolomite deposits are found. These quarries are carefully selected based on factors such as quality, purity, and accessibility. Once identified, techniques such as drilling and blasting are used to extract large blocks of dolomite from the earth’s crust.

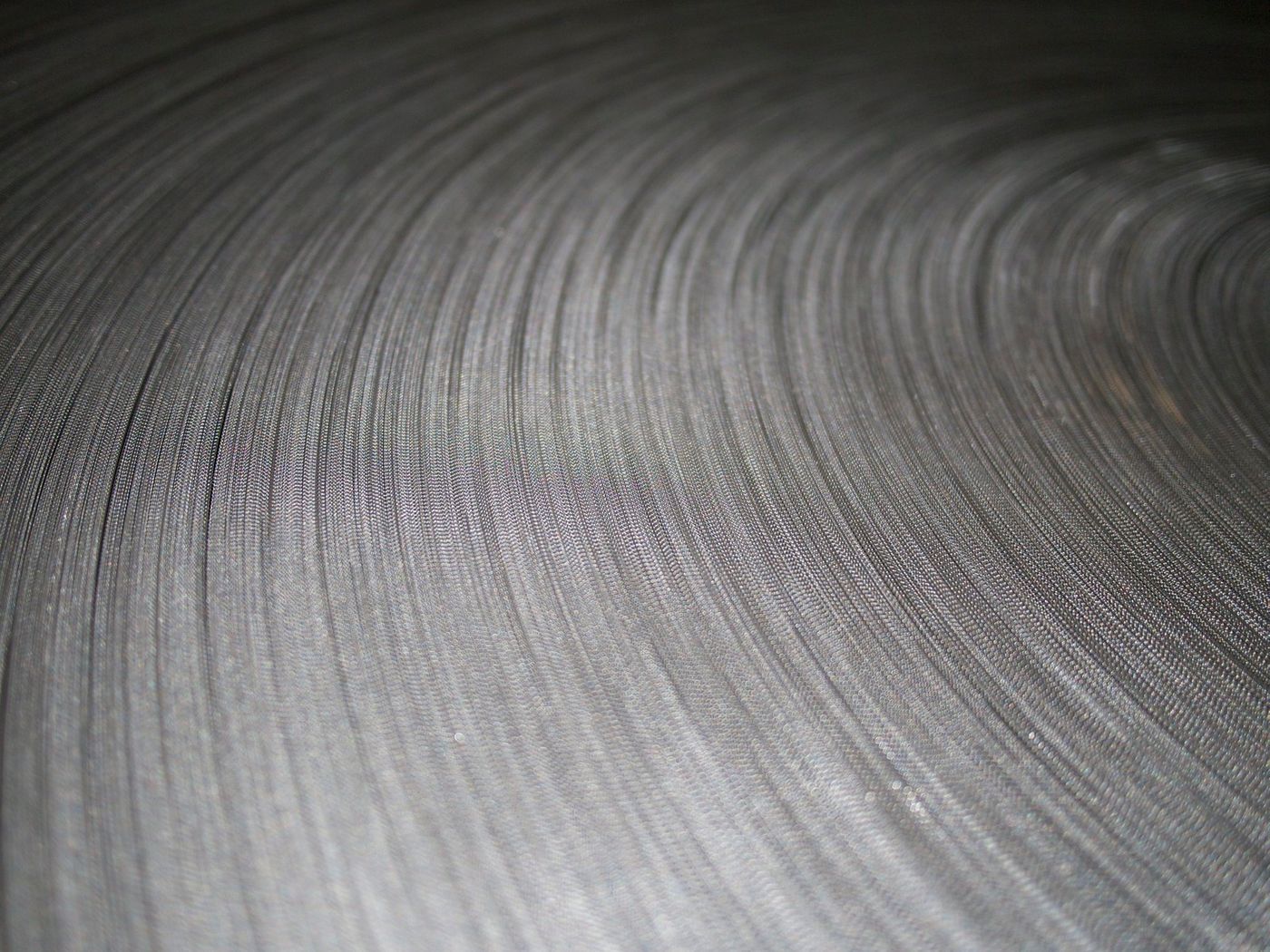

2. Crushing and Screening: After extraction, the raw dolomite goes through a series of crushing and screening processes. This involves breaking down large chunks of dolomite into smaller pieces using heavy machinery like jaw crushers and cone crushers. The crushed material is then sorted by size using screens to remove any impurities or oversized particles.

3. Grinding and Milling: The next step in the process is grinding and milling, which involves reducing the size of the crushed dolomite even further into fine powder form. This process improves the physical properties of the mineral while also making it easier to handle and transport.

Importance of Sustainability in Dolomite Mining

Sustainability has become a major concern in the mining industry, and dolomite mining is no exception. As global demand for this valuable mineral continues to rise, it is important for companies like Wigmore Trading to prioritize sustainability in their mining practices.

But what exactly does sustainability mean in the context of dolomite mining? In simple terms, it refers to the responsible and ethical use of natural resources while ensuring that future generations are not deprived of these resources. This involves minimizing negative impacts on the environment, promoting social responsibility, and maintaining economic viability.

One of the main reasons why sustainability is crucial in dolomite mining is because it helps to protect the environment. Dolomite mines typically involve extensive excavation and blasting activities, which can result in significant damage to surrounding ecosystems if not managed properly. This includes disruption of wildlife habitats, air and water pollution from drilling and transportation equipment, as well as potential risks to human health.

By implementing sustainable practices such as proper waste management, reforestation efforts, and monitoring air and water quality, Wigmore Trading aims to minimize its environmental footprint during the dolomite extraction process. This not only benefits local communities by preserving their natural surroundings but also ensures the long-term viability of the mine itself.

Collaborating with Buyers Worldwide: Benefits and Challenges

Collaborating with buyers worldwide has become a crucial aspect of the mining industry, especially for companies like Wigmore Trading that operate on a global scale. The benefits of such collaborations are undeniable, from increased market reach to access to new technologies and resources. However, as with any business partnership, there are also challenges that come along with it. In this section, we will dive deeper into the benefits and challenges of collaborating with buyers worldwide in the dolomite mining process.

Benefits:

1. Increased Market Reach: Collaborating with buyers worldwide allows companies like Wigmore Trading to expand their market reach beyond their local region or country. By tapping into international markets, they can sell their products to a wider customer base, leading to increased sales and revenue.

2. Access to New Technologies: Working with buyers from different parts of the world also means exposure to new technologies and best practices in the mining industry. This exchange of knowledge can help improve efficiency and productivity in operations at Wigmore Trading.

3. Diversification of Risk: Collaborating with international buyers helps diversify risks associated with economic downturns or changes in regulations in one particular market. If there is a decline in demand for dolomite in one region, Wigmore Trading can still rely on other markets where demand may remain strong.

4. Cultural Exchange: Working closely with international buyers also provides opportunities for cultural exchange and understanding. This not only enhances business relationships but also creates an environment for learning and personal growth.

Conclusion: The Future of Dolomite Mining

Conclusion: The Future of Dolomite Mining

As we have seen in this blog post, dolomite mining is a crucial industry for the production and supply of various materials such as construction aggregates, fertilizers, and industrial chemicals. However, with environmental concerns becoming more pressing and global demand for resources increasing, it is essential to consider the future of dolomite mining.

One potential issue that may impact the future of dolomite mining is its sustainability. As with any mining activity, there are concerns about depletion of resources and environmental degradation. Therefore, it is vital for companies to implement sustainable practices that minimize their impact on the environment while still meeting the demand for dolomite.

In recent years, there has been a growing trend towards sustainable mining practices in the industry. This includes using advanced technologies to reduce water consumption and emissions, implementing land restoration programs, and promoting biodiversity conservation in affected areas. These efforts not only help to preserve the environment but also contribute to the long-term viability of dolomite mining operations.

Another factor that will shape the future of dolomite mining is technological advancements. With new innovations emerging every day in industries like automation and robotics, it is likely that these technologies will also be incorporated into the mining process. This could lead to increased efficiency and safety while reducing costs and environmental impact.

Comments are closed.