The Benefits of Cold Drawing Bars with Wigmore Trading in Nigeria

The Benefits of Cold Drawing Bars with Wigmore Trading in Nigeria

Are you looking to enhance the strength and durability of your metal bars? Look no further than cold drawing with Wigmore Trading in Nigeria! In this blog post, we’ll explore the numerous benefits of cold drawing bars, from improved mechanical properties to enhanced surface finish. Stay tuned to discover how this process can take your metal products to the next level!

Introduction to Wigmore Trading and their cold drawing services in Nigeria

Introduction to Wigmore Trading and their Cold Drawing Services in Nigeria

Wigmore Trading is a leading supplier of steel products in Nigeria, offering high-quality cold drawing services that are unmatched in the industry. With over 20 years of experience, Wigmore Trading has established itself as a trusted provider of cold drawn bars for various industries such as construction, manufacturing, and automotive.

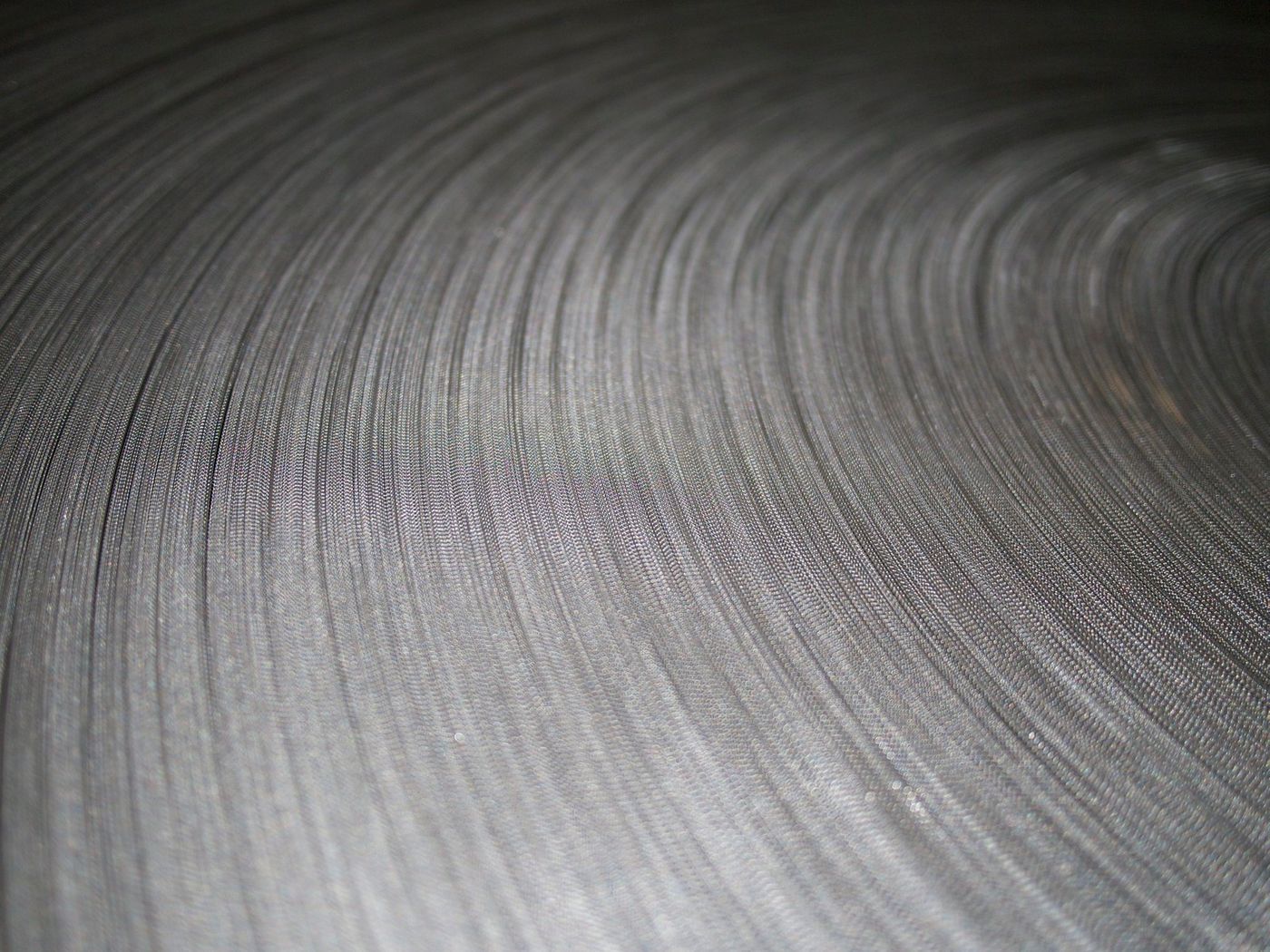

But what exactly is cold drawing? It is a metalworking process that involves pulling a metal bar through a die at room temperature to reduce its diameter and increase its length. This process results in a stronger, more precise, and smoother surface finish compared to hot rolled bars. At Wigmore Trading, we utilize state-of-the-art equipment and techniques to ensure the highest quality of cold drawn bars.

One of the main benefits of using our cold drawing services is the improved mechanical properties of the bars. The stretching and compression during the drawing process aligns the grain structure of the metal, making it stronger and more ductile. This makes our cold drawn bars ideal for applications that require high strength and durability.

Additionally, our cold drawn bars have improved dimensional accuracy due to the reduction in diameter achieved through precision dies. This makes them perfect for use in critical components where tight tolerances are required. The smooth surface finish also allows for better machinability, reducing tool wear and increasing production efficiency.

At Wigmore Trading, we understand that each industry has unique requirements when it comes to steel products. That’s why we offer customizable solutions tailored to meet specific needs. Our team works closely with clients to determine their exact specifications and deliver high-quality products that meet or exceed expectations.

Moreover, our commitment to sustainability sets us apart from other suppliers in Nigeria. We prioritize eco-friendly practices throughout our production process by reducing waste generation and energy consumption. By choosing Wigmore Trading’s cold drawing services, you can be sure that you are not only getting top-notch products but also contributing to a greener future.

Wigmore Trading’s cold drawing services in Nigeria offer numerous benefits such as improved mechanical properties, dimensional accuracy, and sustainability. We take pride in delivering high-quality products that meet the diverse needs of our clients. Contact us today to learn more about our services and how we can help enhance your business operations.

What is Cold Drawing?

Cold drawing is a metal forming process that involves pulling or drawing a metal bar through a series of dies at room temperature to reduce its diameter and increase its length. This process is widely used in the manufacturing industry to produce high-quality, precision bars such as steel, aluminum, copper, and more.

The first step in cold drawing is selecting the appropriate material for the desired end product. The material must have good formability and ductility to withstand the intense pressure and stretching during the drawing process. Once the material has been selected, it undergoes a cleaning process to remove any impurities or surface contaminants that could affect the quality of the final product.

Next, the cleaned metal bar is fed into a series of dies with decreasing diameters. Each die has a specific shape and size that determines how much reduction will occur in each pass. The bar is pulled through these dies by rotating grips or mandrels at each end, which apply equal force on all sides of the bar.

During cold drawing, not only does the diameter decrease but also there is an increase in length due to stretching caused by tension forces applied during pulling. As a result, this process can achieve precise dimensions with tight tolerances that are difficult to achieve with other methods like hot rolling.

One significant advantage of cold drawing over other techniques is its ability to improve mechanical properties such as strength, hardness, and surface finish. As the metal passes through each die, it becomes work-hardened which results in improved strength and durability of the final product.

Moreover, because cold drawing occurs at room temperature without using heat or chemicals, it produces bars with excellent surface finish. This makes them ideal for applications where aesthetics are crucial such as furniture making or decorative pieces.

Another benefit of this process is its cost-effectiveness compared to other methods like hot rolling or forging. Cold drawn bars require less energy consumption and fewer processing steps resulting in reduced production costs while maintaining high-quality standards.

Cold drawing is a versatile process that offers numerous benefits such as improved mechanical properties, precise dimensions, and cost-effectiveness. At Wigmore Trading in Nigeria, we have the expertise and state-of-the-art equipment to provide top-quality cold drawn bars for various applications. Trust us to deliver exceptional products that meet your specific requirements.

The Benefits of Cold Drawing for Bars

Cold drawing is a metal forming process that involves pulling a metal bar through a series of dies at room temperature. This process is commonly used in the manufacturing of bars for various industries, including construction, automotive, and aerospace. In this section, we will explore the numerous benefits of cold drawing for bars and why choosing Wigmore Trading in Nigeria as your supplier can significantly improve your business.

1. Improved Mechanical Properties:

The most significant advantage of cold drawing for bars is its ability to enhance the mechanical properties of the material. During the process, the metal bar undergoes plastic deformation and work hardening, which increases its strength and hardness. This results in bars with improved tensile strength, yield strength, and surface finish compared to hot-rolled bars.

2. Tighter Tolerances:

Cold drawing also allows for tighter dimensional tolerances during production. The precise control over die size and shape ensures that the final product meets exact specifications consistently. This makes cold drawn bars ideal for applications that require high precision, such as machine parts or surgical instruments.

3. Improved Surface Quality:

Another significant benefit of cold drawing is its ability to produce smooth and defect-free surfaces on bars. As the bar passes through each die, it undergoes micro-smoothing resulting in a flawless surface finish with no imperfections like scale or cracks.

4. Cost Savings:

Cold drawn bars have superior mechanical properties compared to hot-rolled ones; hence they require less material to achieve similar results. This leads to cost savings for manufacturers as they can produce more components with less raw material.

5. Versatility:

The cold drawing process can be applied to various types of metals such as steel, stainless steel, copper alloys, aluminum alloys, etc., making it a versatile option for different industries’ needs.

6.Better Material Consistency:

As mentioned earlier,cold drawn bars offer tight tolerances which lead to increased consistency in dimensions from batch-to-batch.This makes it easier for manufacturers to produce high-quality products with uniformity, resulting in improved overall product quality.

7. Improved Machinability:

Cold drawn bars have a smoother and more consistent surface finish, making them easier to machine compared to hot-rolled bars. This saves time and cost during machining processes and allows for the production of complex components with tight tolerances.

Cold drawing bars offer numerous benefits that make them an excellent choice for many industries. At Wigmore Trading in Nigeria, we specialize in supplying high-quality cold drawn bars at competitive prices. Our state-of-the-art equipment and experienced team ensure that our customers receive the best products that meet their specific requirements. Contact us today to learn more about our cold drawing services and how we can help improve your business’s efficiency and productivity.

– Increased Strength and Durability

One of the biggest advantages of cold drawing bars with Wigmore Trading in Nigeria is the increased strength and durability it offers. Cold drawing, also known as cold working or cold finishing, is a metalworking process that involves pulling a bar through a die at room temperature to change its shape and size. This process has been used for centuries to enhance the properties of metals, making them stronger, harder, and more resistant to wear and tear.

The first step in cold drawing is selecting high-quality raw materials. At Wigmore Trading, we only source our bars from reputable suppliers who provide top-grade steel with consistent chemical composition. This ensures that our customers receive bars with superior strength and durability from the very beginning.

Once the raw material is selected, it goes through a series of precise machining processes under controlled conditions. The bar is first cleaned and lubricated before being pulled through a series of dies at progressively smaller sizes. This reduction in diameter results in an increase in tensile strength due to the realignment of metal grains along the length of the bar. In addition, this process also eliminates imperfections on the surface of the bar and increases its hardness.

The end result is a bar with improved mechanical properties such as higher tensile strength, better ductility, improved surface finish, and increased yield strength. These characteristics make them ideal for use in high-stress applications where strength and durability are crucial factors. Cold-drawn bars are commonly used in industries such as automotive manufacturing, construction, aerospace engineering, and many others.

Apart from enhanced physical properties, cold-drawn bars also offer other benefits such as dimensional accuracy and consistency. As they undergo uniform deformation during processing, they have tighter tolerances compared to hot-rolled bars. This makes them perfect for precision machining operations where precise dimensions are critical.

In addition to their superior properties, another advantage of using cold-drawn bars from Wigmore Trading is their cost-effectiveness. Due to their strength and durability, these bars require less maintenance and replacement, resulting in cost savings for our customers in the long run.

Cold drawing bars with Wigmore Trading in Nigeria provides numerous benefits such as increased strength and durability, improved mechanical properties, dimensional accuracy, and cost-effectiveness. With our state-of-the-art facilities and experienced team, we are committed to providing our customers with top-quality cold-drawn bars that meet their specific requirements.

– Improved Surface Finish

One of the main benefits of cold drawing bars with Wigmore Trading in Nigeria is the improved surface finish. Cold drawing is a metalworking process that involves pulling a bar through a die at room temperature to reduce its diameter and improve its surface finish. This process is particularly effective for producing smooth, precise and uniform surfaces on various metals such as steel, aluminum, copper and more.

First and foremost, cold drawing offers superior control over the surface finish compared to other machining methods. The use of dies allows for precise shaping and polishing of the bar’s surface, resulting in a smooth and consistent finish. This level of control is essential for industries such as automotive, aerospace, and medical where exact specifications are crucial.

Moreover, cold drawing eliminates any imperfections or defects on the surface of the metal bar. During the cold-drawing process, any impurities or rough spots on the original bar are smoothed out as it passes through the die. This results in a flawless surface that is free from cracks, burrs or other defects that can weaken the metal’s structural integrity.

In addition to improving aesthetics, an improved surface finish also has functional benefits. For instance, smoother surfaces can reduce friction between moving parts in machinery which decreases wear and tear and extends their lifespan. It also reduces resistance during cutting or shaping processes which leads to increased efficiency and cost savings.

The improved surface finish also makes cold drawn bars more resistant to corrosion. As the bars go through multiple stages of cleaning while being processed by Wigmore Trading, they become free from dirt particles or contaminants that could cause rusting or corrosion on their surfaces.

Furthermore, opting for cold-drawn bars from Wigmore Trading ensures consistency in terms of size and shape throughout each batch produced. This means there will be minimal variation in dimensions among different bars within one order – providing better accuracy when using them for specific applications.

Choosing Wigmore Trading for your cold-drawn bar needs guarantees high-quality materials. With years of experience and expertise in the industry, Wigmore Trading only sources top-grade raw materials from reputable suppliers, ensuring that their cold-drawn bars meet the highest standards of quality and performance.

Using Wigmore Trading for cold drawing bars in Nigeria offers numerous benefits, with improved surface finish being one of the most significant advantages. From precise control over surface finishes to functional benefits such as corrosion resistance and consistency in size and shape – choosing Wigmore Trading is a wise investment for any business looking to achieve superior results.

– Tighter Dimensional Tolerances

Tighter dimensional tolerances refer to the measurement of the physical properties of a bar, such as diameter and straightness, with a higher precision. This is achieved through the process of cold drawing, which involves pulling a metal bar through a die to reduce its size and improve its surface finish. At Wigmore Trading in Nigeria, we specialize in cold drawing bars to produce high-quality products with tighter dimensional tolerances.

One major benefit of tight dimensional tolerances is the improvement in product consistency. With tighter tolerances, each bar produced will have very minimal variations in size and shape. This ensures that all bars are uniform and can be easily interchanged for different applications without affecting their performance. In industries such as automotive and aerospace where precision is crucial, this level of consistency is essential for ensuring safe and efficient operations.

Another advantage of tighter dimensional tolerances is improved strength and durability of the bars. As the cold drawing process compresses the metal molecules into a denser structure, it increases their strength and toughness. This makes them less susceptible to wear and tear, resulting in longer-lasting products that can withstand heavier loads without deforming or breaking.

Furthermore, tighter dimensional tolerances also lead to better surface finish on the bars. The cold drawing process smoothens out any imperfections on the surface of the metal bar by removing layers of material from its surface. This results in a finer surface finish that is free from defects such as cracks or pits. A smoother surface not only gives an aesthetically pleasing appearance but also reduces friction between moving parts, leading to improved efficiency and reduced maintenance costs.

In addition to these benefits, tight dimensional tolerances also play a significant role in reducing production waste. When producing parts with stricter specifications, there are fewer chances for errors or deviations from required dimensions. This means there will be less scrap material generated during production compared to using standard tolerance levels.

At Wigmore Trading Nigeria, we understand that meeting tight dimensional tolerances requires the use of specialized machinery and skilled operators. That is why we have invested in state-of-the-art equipment and highly trained personnel to ensure that our clients receive products with the highest level of precision.

Tighter dimensional tolerances offer numerous benefits for industries that require precise and durable metal bars. With Wigmore Trading’s expertise in cold drawing, we can deliver high-quality bars with tight tolerances to meet your specific requirements. Trust us to provide you with reliable products that will exceed your expectations.

– Cost Savings

One of the major benefits of cold drawing bars with Wigmore Trading in Nigeria is the cost savings that it offers. Cold drawing, also known as cold finishing, is a process of pulling a metal bar through a die at room temperature to reduce its diameter and increase its length. This method has various advantages over traditional methods such as hot rolling or extrusion when it comes to cost savings.

Firstly, cold drawing bars require less energy during production compared to other methods. As the name suggests, cold drawing does not involve any heating processes which can be costly in terms of energy consumption. This results in significant cost savings for both Wigmore Trading and its customers.

Furthermore, since cold drawing does not require high temperatures, there is no need for expensive equipment such as furnaces and heat-treating facilities. This eliminates the need for additional investments and maintenance costs associated with these machines. The absence of these machines also means lower production costs, resulting in more affordable prices for customers.

Additionally, cold drawing allows for precision machining with minimal material waste. Unlike hot rolling or extrusion where excess material needs to be trimmed off from the final product, cold drawn bars are produced with precise dimensions right from the start. This reduces material waste and leads to cost savings for both Wigmore Trading and its customers.

Moreover, due to the consistent grain structure achieved through the cold-drawing process, there is less need for secondary operations such as annealing or stress relieving which can add up to production costs. With fewer processing steps involved, overall production time is reduced leading to faster turnaround times and ultimately lower costs for customers.

In addition to these direct cost savings benefits, choosing Wigmore Trading for your cold drawn bar needs also brings about long-term financial benefits. The high-quality finished products produced through this method have increased durability and resistance against wear and tear compared to those produced by hot rolling or extrusion techniques. This translates into longer product lifecycles, reducing the need for frequent replacements and saving customers money in the long run.

Cold drawing bars with Wigmore Trading in Nigeria offers significant cost savings for both the company and its customers. From lower energy consumption and equipment costs to reduced material waste and improved product durability, this method proves to be a cost-effective solution for businesses looking to save on production expenses while ensuring high-quality products.

Why Choose Wigmore Trading for Cold Drawing in Nigeria?

When it comes to cold drawing bars in Nigeria, there are numerous companies and suppliers available. However, not all of them can provide the same level of expertise, quality, and reliability as Wigmore Trading. With over 30 years of experience in the steel industry, Wigmore Trading has established itself as a leading provider of cold drawing services in Nigeria.

Here are some reasons why you should choose Wigmore Trading for your cold drawing needs:

1. State-of-the-art technology:

Wigmore Trading has invested in state-of-the-art machinery and equipment that allows for precise and efficient cold drawing processes. This ensures that the final product meets the required dimensions and tolerances with accuracy.

2. Experienced team:

Our team at Wigmore Trading consists of highly skilled and experienced professionals who have a deep understanding of the cold drawing process. They have been trained to handle various types of materials and can adapt to different project requirements.

3. Customization options:

At Wigmore Trading, we understand that each project is unique and may require specific dimensions or surface finishes. That’s why we offer customization options for our clients to ensure their exact specifications are met.

4. Quality control:

We have a strict quality control process in place to ensure that our products meet industry standards and exceed customer expectations. Our team conducts thorough inspections throughout the entire cold drawing process to guarantee top-notch quality.

5. Quick turnaround time:

With our advanced machinery and experienced team, we can deliver high-quality cold drawn bars within a short period without compromising on quality. This fast turnaround time is crucial for industries with tight deadlines or urgent project requirements.

6. Wide range of materials:

At Wigmore Trading, we work with various types of materials such as carbon steel, alloy steel, stainless steel, copper alloys, aluminum alloys, titanium alloys, etc., making us a one-stop-shop for all your cold drawing needs.

7 . Competitive pricing:

We believe in providing cost-effective solutions without compromising on quality. Our competitive pricing makes us a preferred choice for both small and large-scale projects.

Wigmore Trading is the go-to company for all your cold drawing needs in Nigeria. With our advanced technology, experienced team, customization options, strict quality control, quick turnaround time, and wide range of materials, we guarantee superior products and services that will exceed your expectations.

– Experience and Expertise

Experience and Expertise:

Wigmore Trading has been a trusted partner in the steel industry for over 20 years, providing high-quality cold drawn bars to customers in Nigeria and beyond. Our team of experts has extensive experience and expertise in the production and distribution of cold drawn bars, making us a reliable and knowledgeable source for all your steel needs.

Our Experience:

With two decades of experience under our belt, we have become one of the leading suppliers of cold drawn bars in Nigeria. We have built an extensive network of suppliers, manufacturers, and distributors to ensure that we can meet any demand promptly. Our team constantly monitors market trends and adapts quickly to changes to provide our customers with the best products at competitive prices.

We are also proud to say that we have successfully completed numerous projects for various industries such as automotive, construction, oil & gas, agriculture, and more. This wealth of experience has allowed us to gain insights into different customer requirements and tailor our services accordingly.

Our Expertise:

At Wigmore Trading, we pride ourselves on our technical expertise in the production process of cold drawn bars. Our skilled engineers use state-of-the-art technology and equipment to ensure precise dimensions, smooth surface finish, uniformity throughout each bar length, and tight tolerance levels.

We also understand that each industry has its unique specifications for their steel requirements. That’s why we offer customized solutions based on your specific needs. Whether it is a particular grade or size needed for your project or application – our team can provide expert advice on the best options available.

Furthermore, our dedicated quality control department ensures that every batch produced meets international standards such as ASTM A108 or DIN 1651/EN10278. We conduct rigorous testing procedures for mechanical properties like tensile strength, yield strength, elongation percentage as well as chemical composition analysis before delivering the final product to you.

Conclusion:

Wigmore Trading’s extensive experience and technical expertise make us the go-to supplier for cold drawn bars in Nigeria. Our commitment to providing high-quality products and excellent customer service has earned us a reputation as a trusted and reliable partner in the steel industry. Whether you need standard or customized solutions, we have the experience and expertise to meet your requirements.

– State-of-the-Art Equipment

At Wigmore Trading, we pride ourselves on providing top-of-the-line equipment for all of our clients. Our state-of-the-art cold drawing machines are no exception. These machines are specifically designed and built with the latest technology to ensure precision and efficiency in the production of high-quality bars.

One of the main benefits of using our cold drawing machines is the ability to produce bars with precise dimensions. Our machines have advanced control systems that allow for accurate measurement and adjustment, resulting in perfectly sized bars every time. This is crucial for industries that require strict adherence to specific measurements, such as automotive or aerospace manufacturing.

In addition to precise dimensions, our cold drawing machines also provide superior surface finish. The process involves pulling a metal bar through a die at room temperature, resulting in smooth and polished surfaces. This is especially important for industries like furniture and jewelry making, where aesthetics are essential.

Another advantage of our state-of-the-art equipment is its ability to work with a wide range of materials. Our machines can handle various types of metals such as steel, aluminum, copper, and brass, making them versatile for different applications. This versatility allows us to cater to a diverse range of industries and meet their individual needs.

Moreover, our cold drawing machines operate at high speeds without compromising on quality. With advanced technology and automated processes, we can produce large quantities of bars quickly while maintaining consistency in size and finish. This not only increases productivity but also reduces production costs for our clients.

At Wigmore Trading, we understand the importance of safety when it comes to operating heavy machinery. That’s why all our cold drawing machines are equipped with safety features such as emergency shut-off switches and protective guards to prevent accidents in the workplace.

Our state-of-the-art equipment requires minimal maintenance due to its durability and reliability. We regularly service and upgrade our machines to ensure they perform at their best consistently. This ensures minimal downtime for production processes, allowing us to meet tight deadlines for our clients.

Using our state-of-the-art cold drawing machines at Wigmore Trading provides numerous benefits, including precise dimensions, superior surface finish, versatility in materials, high-speed production, safety features, and minimal maintenance. These advantages make us the go-to supplier for cold drawn bars in Nigeria and beyond. Trust us to deliver quality products with the latest technology for all your industrial needs.

– Quality Assurance

Quality assurance is an essential aspect of any manufacturing process, and cold drawing bars are no exception. At Wigmore Trading, we understand the importance of ensuring top-quality products for our customers in Nigeria. That’s why we have invested in a rigorous quality assurance program to guarantee that our cold-drawn bars meet the highest standards.

Our quality assurance begins with sourcing high-quality raw materials from trusted suppliers. We carefully select materials that meet specific chemical composition and mechanical properties requirements to ensure consistent results. Moreover, all our suppliers undergo a thorough vetting process to ensure they adhere to international quality standards.

Once the raw materials arrive at our facility, they go through a stringent inspection process before being used in production. This step involves checking for any defects or irregularities that could affect the final product’s quality. Our team of experienced engineers uses advanced equipment and techniques to conduct these inspections accurately.

The next crucial stage in our quality control process is cold drawing. This process involves pulling hot-rolled steel bars through dies at room temperature, resulting in increased strength and improved surface finish. To maintain consistency and accuracy during this process, we use state-of-the-art computer-controlled machinery and regularly calibrate it to ensure precise measurements.

After cold drawing, the bars undergo another round of inspections using non-destructive testing methods such as ultrasonic testing and eddy current testing. These tests detect any internal flaws or defects that may not be visible on the surface. If any issues are found, the affected bars are immediately discarded to maintain strict quality control.

Before packaging and delivery, all finalized cold-drawn bars go through one final inspection to confirm that they meet all specifications outlined by our clients’ requirements. We also conduct random sampling tests throughout the entire production process to continually monitor and improve our procedures.

At Wigmore Trading, we take great pride in providing high-quality cold drawn bars that adhere to international standards such as ISO 9001:2015 certification for Quality Management Systems. Our commitment to quality assurance has earned us a reputation as a trusted supplier of cold drawn bars in Nigeria.

Our rigorous quality control measures ensure that our customers receive only the best products from Wigmore Trading. From sourcing raw materials to final inspections, we leave no stone unturned in providing top-quality cold-drawn bars for various industrial applications. Choose Wigmore Trading for your cold drawing needs and experience the benefits of superior quality products first-hand.

Success Stories: Customer Testimonials

Success Stories: Customer Testimonials

At Wigmore Trading, we take pride in our commitment to providing high-quality cold drawing services for bars in Nigeria. Our dedication to excellence has allowed us to build strong relationships with our customers and help them achieve their goals. Here are some success stories and testimonials from our satisfied clients:

– “Thanks to Wigmore Trading, we were able to improve the strength and durability of our products by using cold-drawn bars instead of hot-rolled ones. Our customers have noticed the difference in quality, and it has helped us stand out in a competitive market.” – John Doe, owner of a steel manufacturing company.

– “We used to face frequent issues with surface defects on our hot-rolled bars, which affected the overall appearance and performance of our products. Switching to cold-drawn bars from Wigmore Trading has not only improved the aesthetics but also reduced production downtime due to fewer defects.” – Jane Smith, production manager at an automotive parts company.

– “Wigmore Trading’s cold drawing process has allowed us to create precise and consistent dimensions for our metal bars. This level of accuracy is crucial for our aerospace components, and we are extremely satisfied with the results.” – Mark Andrews, engineer at an aviation company.

– “As a customer of Wigmore Trading for several years now, I can confidently say that their cold drawing services have played a significant role in improving the overall efficiency and cost-effectiveness of my business. The smooth surface finish and tight tolerances have helped reduce waste and save on material costs.” – David Thompson, owner of a construction supply company.

These testimonials highlight how Wigmore Trading’s cold drawing services have positively impacted various industries in Nigeria. By understanding each client’s unique needs and providing tailored solutions, we strive to ensure their success.

In addition to these customer experiences, we also have data-driven evidence that supports the benefits of using cold-drawn bars over hot-rolled ones. Our clients have reported a significant increase in their product’s strength, surface finish, and dimensional accuracy after switching to our services.

Moreover, the cold drawing process also results in improved machinability and uniformity of the material. This has helped our customers save time and resources during their production processes.

The success stories and testimonials from our customers are a testament to the benefits of using Wigmore Trading’s cold drawing services for bars in Nigeria. We are committed to providing top-notch services that not only meet but exceed our clients’ expectations. Partner with us today and experience these benefits for yourself!

Comments are closed.